Cigarette body for circumferential heating non-burning cigarette

A heat-not-burn, cigarette technology, used in applications, tobacco, smoker's products, etc., can solve the problems of great influence of suction resistance and taste, and cigarettes can not meet the design requirements, so as to increase the amount of smoke and improve smoking. The effect of suction experience and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

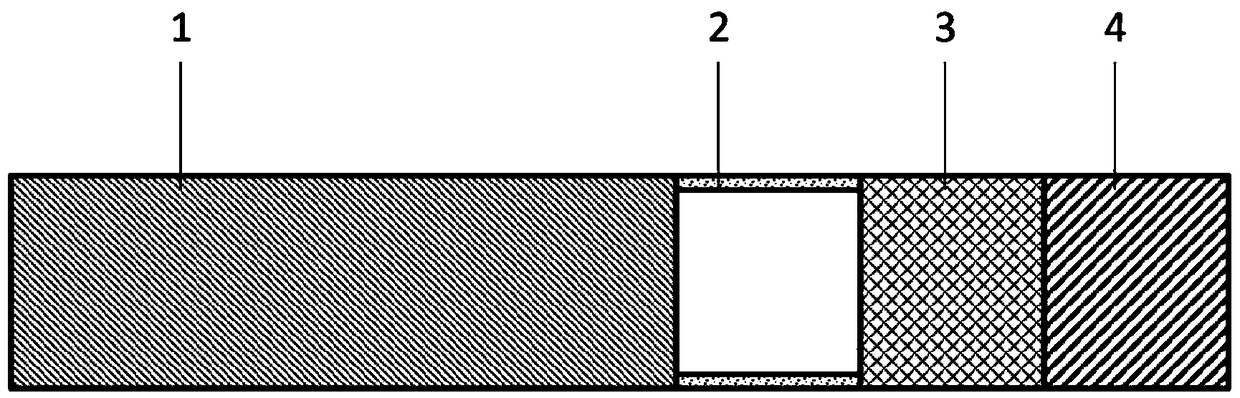

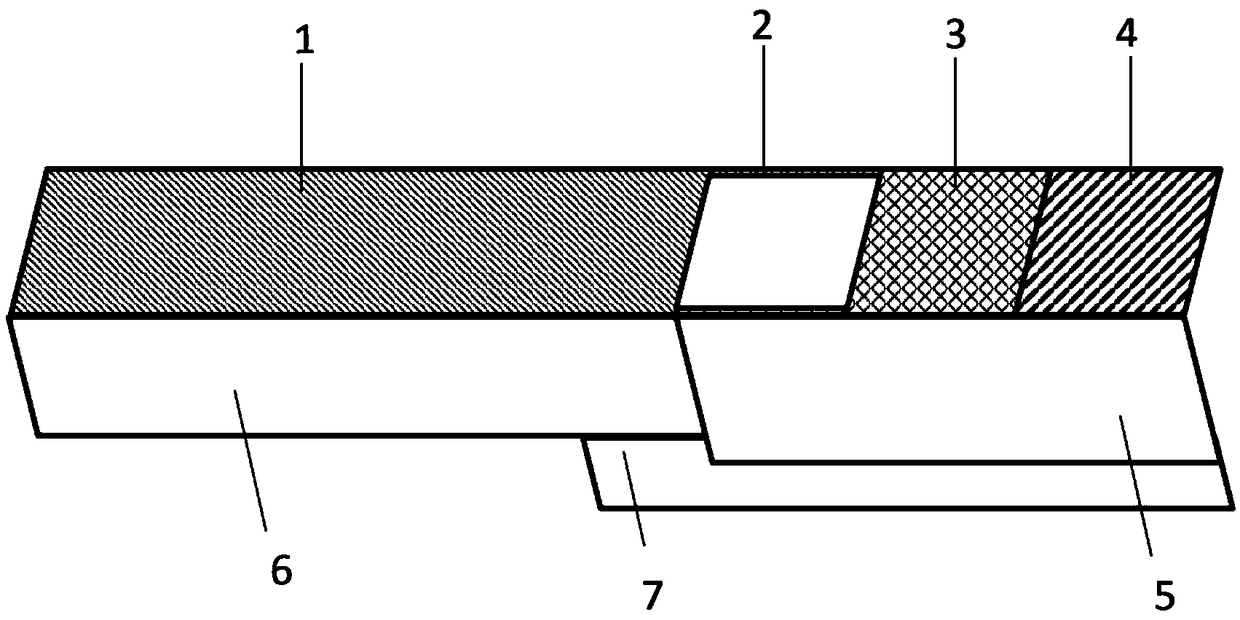

[0035] Such as figure 1 As shown, this embodiment is a cigarette stick for circumferential heat-not-burn cigarettes, which is composed of a smoking core base material 1, a paper tube unit 2, a filter rod unit 3, and a condensation unit 4;

[0036] Composite molding paper 5 is arranged on the outside of the paper tube unit 2, the filter rod unit 3 and the condensation unit 4;

[0037] Cigarette paper 6 is arranged on the outside of the base material 1 of the smoking core;

[0038] A tipping paper 7 is provided outside the composite molding paper 5 and the cigarette paper 6;

[0039] The condensing unit 4 is made of gathered polylactic acid film.

[0040] The paper tube unit 2 is made by composite processing of paper materials.

[0041] The wall thickness of the paper tube unit 2 is 0.25mm.

[0042] The length of the paper tube unit 2 is 1 / 3 of the total length of the paper tube unit 2 , the filter rod unit 3 and the condensation unit 4 .

[0043] The condensing unit 4 is a...

Embodiment 2

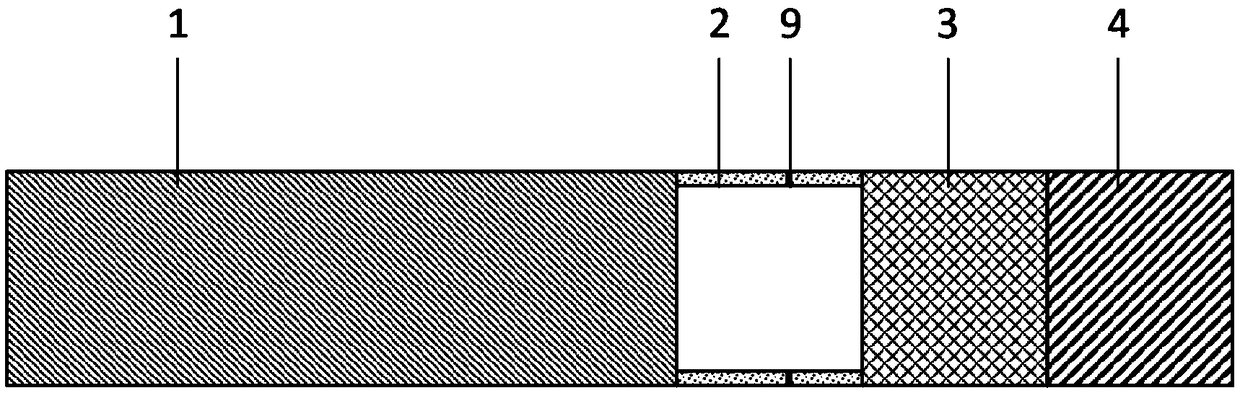

[0045] Such as image 3 As shown, this embodiment is a cigarette stick for circumferential heat-not-burn cigarettes, which is composed of a smoking core base material 1, a paper tube unit 2, a filter rod unit 3, and a condensation unit 4;

[0046] Composite molding paper 5 is arranged on the outside of the paper tube unit 2, the filter rod unit 3 and the condensation unit 4;

[0047] Cigarette paper 6 is arranged on the outside of the base material 1 of the smoking core;

[0048] A tipping paper 7 is provided outside the composite molding paper 5 and the cigarette paper 6;

[0049] The condensing unit 4 is formed by gathering and processing polylactic acid tow.

[0050] The paper tube unit 2 is made by composite processing of paper materials.

[0051] The paper tube unit 2 has ventilation holes 9 .

[0052] The ventilation holes are prepared by laser drilling.

[0053] The wall thickness of the paper tube unit 2 is 0.25mm.

[0054] The length of the paper tube unit 2 is ...

Embodiment 3

[0057] Such as Figure 4 As shown, this embodiment is a cigarette stick for circumferential heat-not-burn cigarettes, which is composed of a smoking core base material 1, a paper tube unit 2, a filter rod unit 3, and a condensation unit 4;

[0058] Composite molding paper 5 is arranged on the outside of the paper tube unit 2, the filter rod unit 3 and the condensation unit 4;

[0059] Cigarette paper 6 is arranged on the outside of the base material 1 of the smoking core;

[0060] A tipping paper 7 is provided outside the composite molding paper 5 and the cigarette paper 6;

[0061] The condensing unit 4 is made of a blend material of diacetate fiber tow and polylactic acid tow.

[0062] The paper tube unit 2 is made by composite processing of paper materials.

[0063]The inner wall of the paper tube unit 2 has an aroma-increasing and cooling layer 10, and the aroma-increasing and cooling layer 10 is a high molecular polymer.

[0064] The wall thickness of the paper tube u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com