Method and device for measuring refractive index of curved optical component based on Brewster's law

A technology of optical components and measuring devices, which is used in the measurement of refractive power, testing optical performance, etc., to achieve generalization, shorten measurement time, and solve dynamic errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

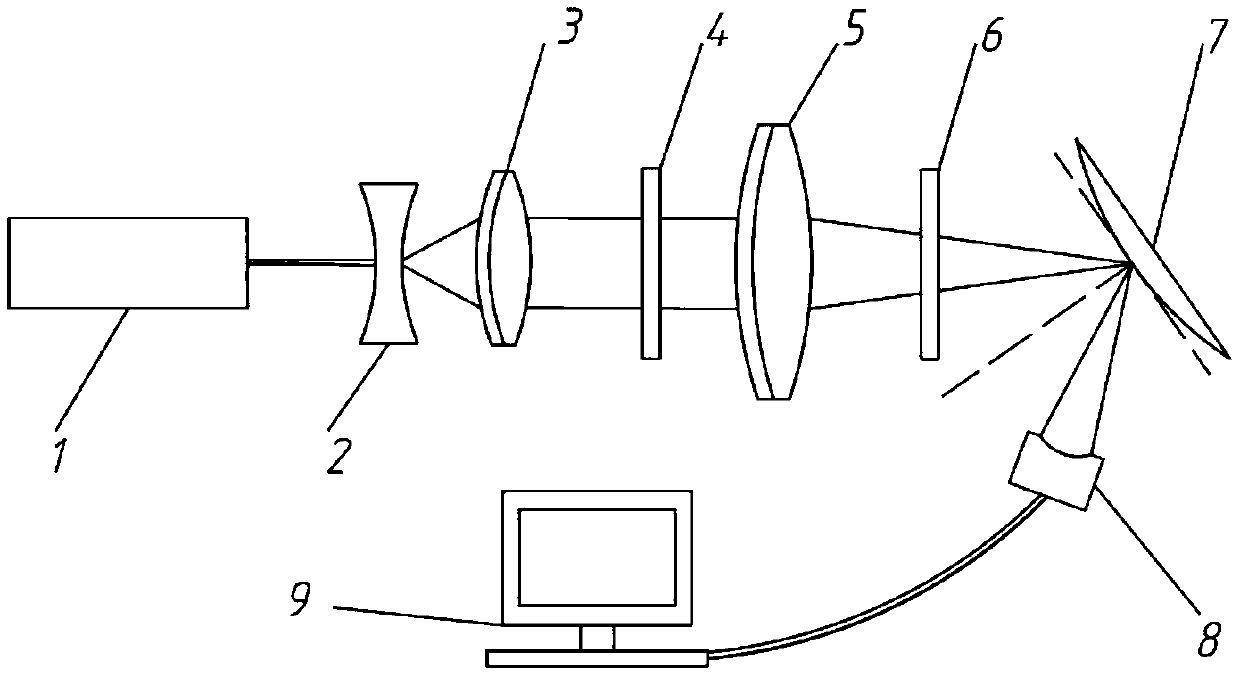

[0039] A device for measuring the refractive index of curved optical elements based on Brewster's law, such as figure 1 As shown, it includes a laser 1 , a beam expander 2 , a collimator 3 , a first linear polarizer 4 , a converging lens 5 , a second linear polarizer 6 , an area array detector 8 , and a computing processing system 9 .

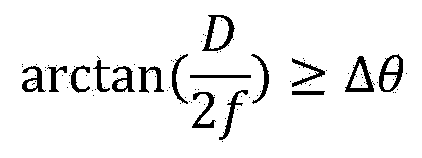

[0040] The medium 7 to be measured in this embodiment is a rectangular prism whose material is K9. During the measurement process, the laser 1 uses a He-Ne laser with a center wavelength of 632.8nm, and the spot diameter is 2mm; the beam expander 2 operates at a wavelength of 450-780nm, and the beam expansion rate is 6 times; the first linear polarizer 4, the first line The extinction ratio of the polarizer 6 is 100:1, and the transmittance is greater than 50%. Taking the horizontal direction as a reference, the polarization angle of the first linear polarizer 4 is 60°, and the polarization angle of the second linear polarizer 6 is 0°; the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com