Heterochromatic blasting bead and application thereof

A technology of bursting beads and different colors, which is applied in the fields of application, tobacco, food science, etc., can solve the problems of reducing consumers' smoking experience, poor compactness of the outer surface of the bead wall, and reducing the desire to smoke, so as to improve the smoking experience Good feeling, good appearance and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

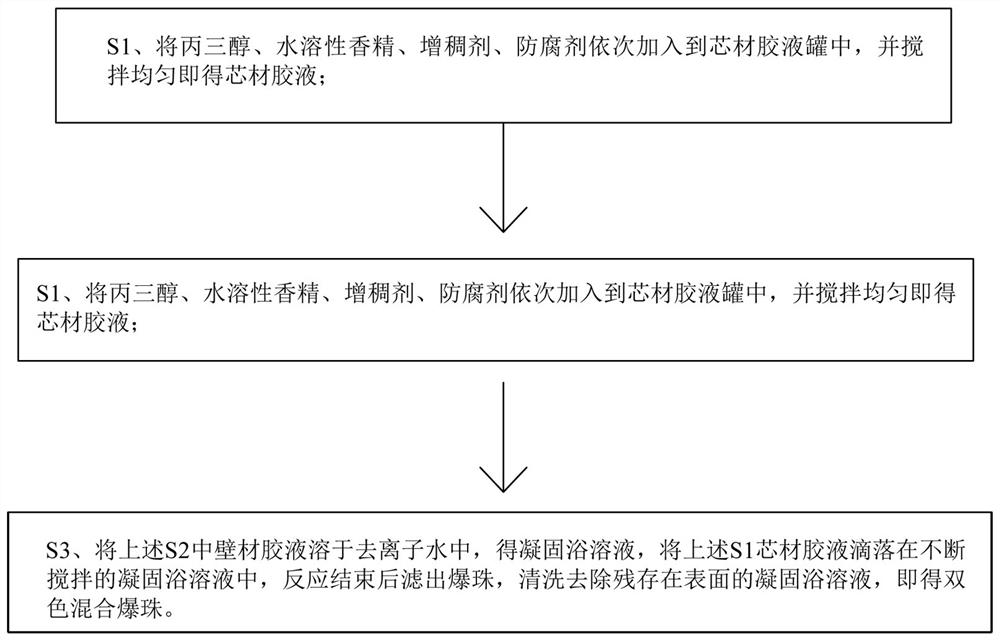

[0047] In the embodiment of the present invention, the preparation method of two-color mixed popping beads specifically includes the following steps:

[0048] S1. Add glycerin, water-soluble essence, thickener and preservative into the core material glue tank in sequence, and stir evenly to obtain the core material glue;

[0049] S2. Add the color-developing glue, hydroxypropyl cellulose, sodium alginate, chloride salt and glycerin into the wall material glue tank, and stir evenly to obtain the wall material glue;

[0050] S3. Dissolve the above-mentioned wall material glue in S2 in deionized water to obtain a coagulation bath solution. Drop the above-mentioned S1 core material glue into the constantly stirring coagulation bath solution. Coagulate the bath solution on the surface to get the two-color mixed popping beads.

Embodiment 1

[0053] A kind of different color quick-fried beads, including a core material and a wall material. The core material is prepared from raw materials comprising the following components: 20g glycerin, 1g rose essence, 1g pectin, 1g lactic acid Streptococcus, the wall material is prepared from raw materials comprising the following components: 100g chromogenic glue, 5g hydroxypropyl cellulose, 5g sodium alginate, 5g calcium chloride, 1g glycerin.

[0054] In this example:

[0055] The preparation process of chromogenic glue solution is as follows:

[0056] a. Add konjac glucomannan-soybean protein isolate composite membrane material into deionized water to prepare a solution, add carmine pigment, and disperse evenly to obtain glue X, wherein konjac glucomannan-soybean protein isolate composite membrane material, The mass ratio of deionized water to carmine pigment is 3:100:1;

[0057] b. Add the konjac glucomannan-zein composite film material into deionized water to prepare a ...

Embodiment 2

[0064] A kind of different color quick-fried beads, comprising a core material and a wall material, in parts by weight, the core material is prepared from raw materials comprising the following components: 22g glycerol, 2g rose essence, 1.2g pectin, 1.2 g nisin, the wall material is prepared from raw materials comprising the following components: 120g chromogenic glue, 6g hydroxypropyl cellulose, 10g sodium alginate, 10g calcium chloride, 5g glycerin.

[0065] In this example:

[0066] The preparation process of chromogenic glue solution is as follows:

[0067] a. Add konjac glucomannan-soybean protein isolate composite membrane material into deionized water to prepare a solution, add carmine pigment, and disperse evenly to obtain glue X, wherein konjac glucomannan-soybean protein isolate composite membrane material, The mass ratio of deionized water to carmine pigment is 3:100:1,

[0068] b. Add the konjac glucomannan-zein composite film material into deionized water to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com