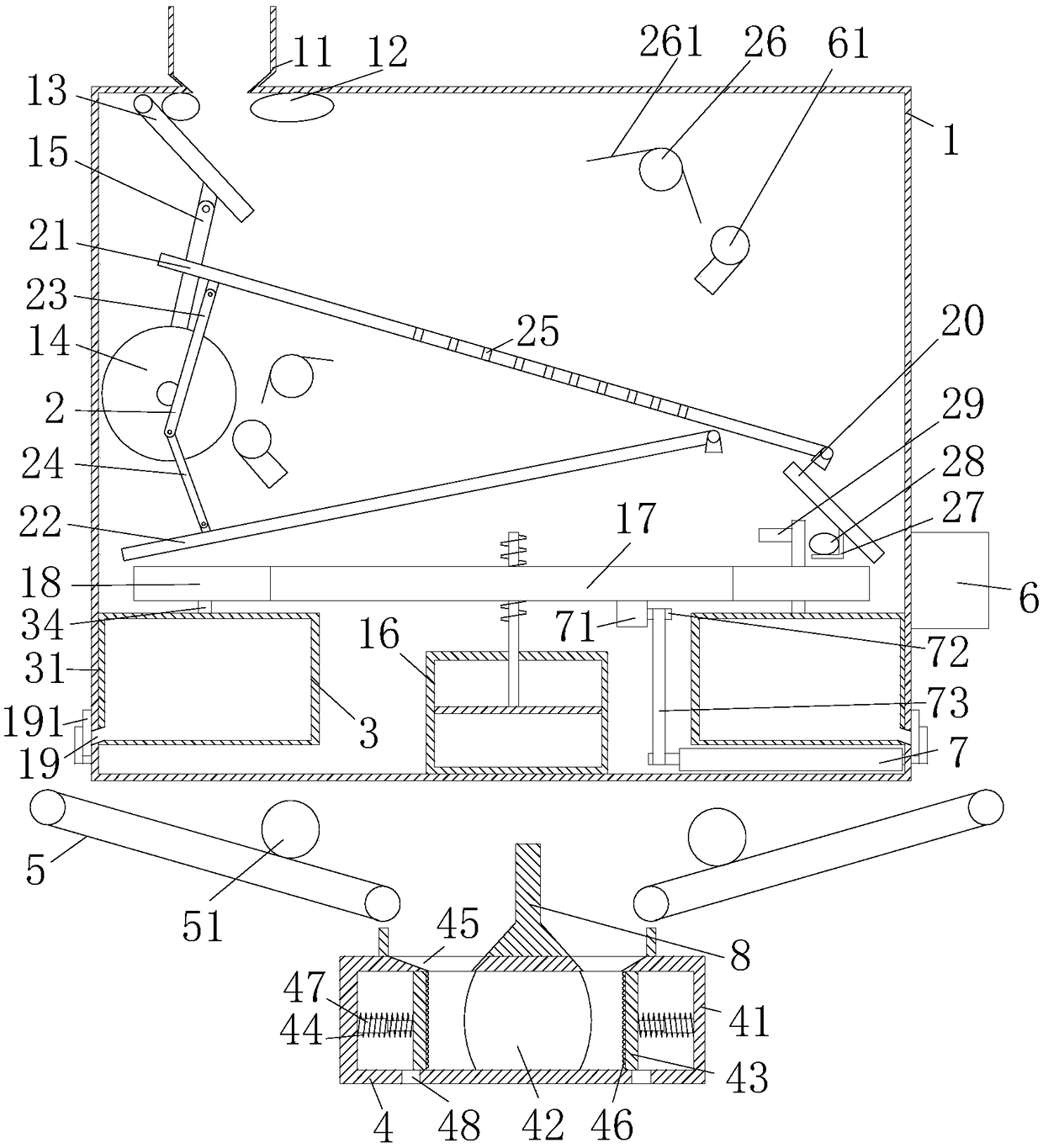

Tea production system

A production system and tea technology, applied in tea treatment before extraction, etc., can solve problems such as uneven stir-frying, decline in tea quality, and incomplete stir-frying of large tea leaves, so as to prevent uneven stir-frying and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] As an embodiment of the present invention, an air outlet 61 is provided above the first conveying plate 21 and the second conveying plate 22, and each of the air outlets 61 communicates with the gas collection chamber 6 through a conduit and a solenoid valve; At this time, the gas in the gas collection chamber 6 is controlled by the electromagnetic valve to enter the air outlet 61, so that the tea leaves can be dried, and the air circulation in the frame body 1 can increase the greening speed of the tea leaves.

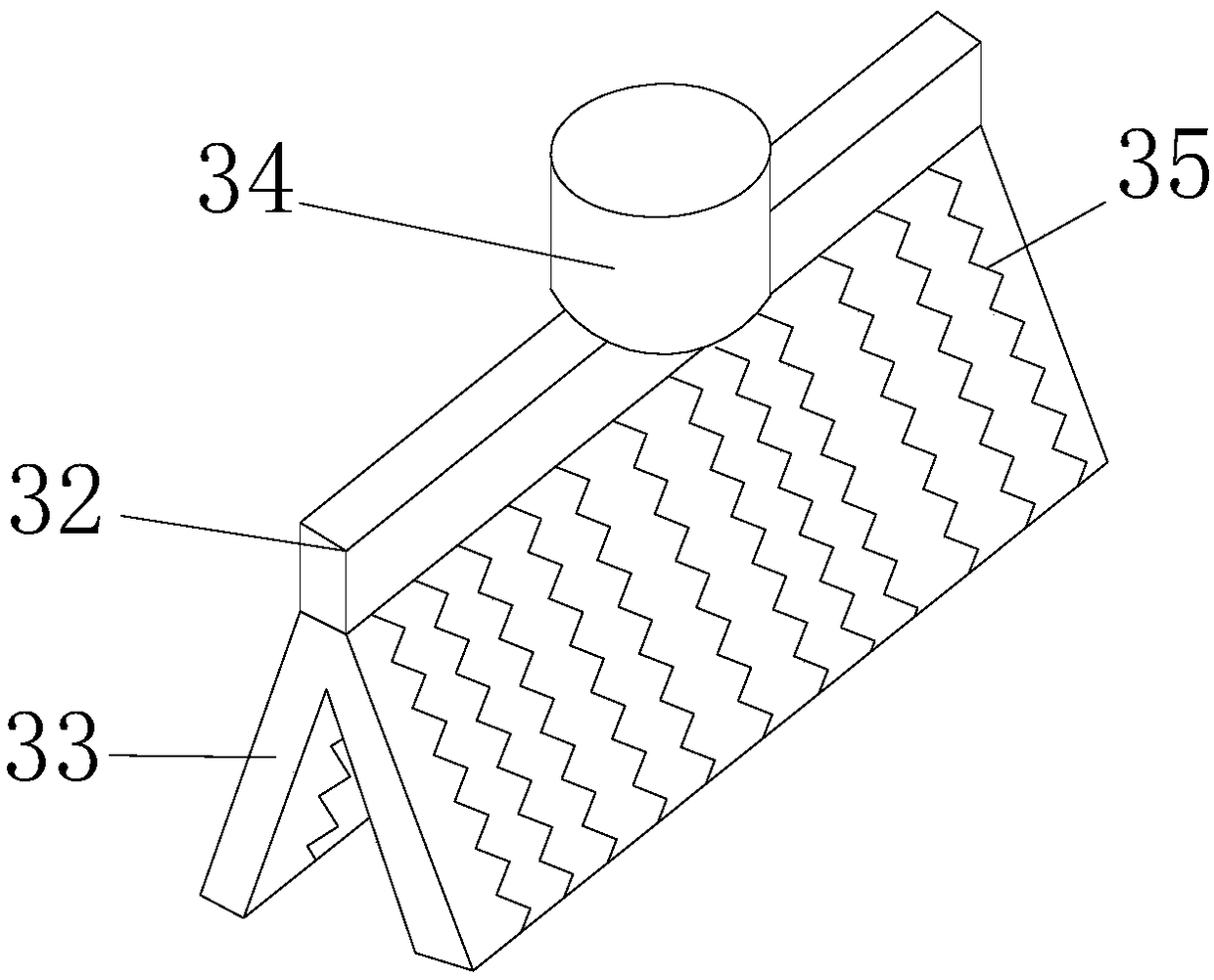

[0033] As an embodiment of the present invention, the stir-frying barrels 31 of the two stir-frying units 3 are all made of stainless steel materials. During operation, the stainless steel materials have the characteristics of strong thermal conductivity and long service life, so that when the tea leaves are stir-fried More even heating and less maintenance.

[0034] As an embodiment of the present invention, between the bottom of the stir-frying barrel 31 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com