Fine machining technology for green tea and machining system thereof

A technology of green tea and process, which is applied in the field of finishing process and processing system of green tea, which can solve the problems of affecting the quality of green tea, frying of tea leaves, affecting the quality of tea, etc., and achieve the effect of preventing deposition, complete greening and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

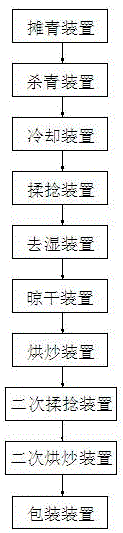

[0054] A finishing process for green tea, which comprises the following steps

[0055] ① Picking, the tea leaves are manually picked from the tea tree according to one bud and one leaf;

[0056] ②, green spreading, put the tea leaves picked in step ① into the green spreading device, spread them evenly to a thickness of 2cm, and stand green for 20 hours;

[0057] ③, greening, put the tea leaves spread out in step ② into the greening tube of the greening device, and bake at a high temperature of 300 ° C, and at the same time, pass hot air at 180 ° C into the greening tube; the greening is 2 minutes;

[0058] ④, cooling, put the tea leaves after step ③ is finished in a cooling device to cool to 25°C;

[0059] ⑤, kneading, put the cooled tea leaves in step ④ into a kneading device and knead them into strips under pressure;

[0060] ⑥, dehumidification, put the tea leaves kneaded in step ⑤ into the dehumidification device, and remove 20% of the internal moisture of the tea leaves...

Embodiment 2

[0067] A finishing process for green tea, which comprises the following steps

[0068] ① Picking, the tea leaves are manually picked from the tea tree according to one bud and one leaf;

[0069] ②, green spreading, put the tea leaves picked in step ① into the green spreading device, spread them evenly to a thickness of 3 cm, and spread them for 15 hours;

[0070] ③, greening, put the tea leaves spread out in step ② into the greening tube of the greening device, and bake at a high temperature of 400 ° C, and at the same time, pass hot air at 120 ° C into the greening tube; the greening is 4 minutes;

[0071] ④, cooling, put the tea leaves after step ③ is finished in a cooling device to cool to 16°C;

[0072] ⑤, kneading, put the cooled tea leaves in step ④ into a kneading device and knead them into strips under pressure;

[0073] ⑥, dehumidification, put the tea leaves kneaded in step ⑤ into the dehumidification device, and remove 30% of the internal moisture of the tea leave...

Embodiment 3

[0080] A finishing process for green tea, which comprises the following steps

[0081] ① Picking, the tea leaves are manually picked from the tea tree according to one bud and one leaf;

[0082] ②, green spreading, put the tea leaves picked in step ① into the green spreading device, spread them evenly to a thickness of 2.5cm, and stand green for 18 hours;

[0083] ③, greening, put the tea leaves spread out in step ② into the greening cylinder of the greening device, and bake at a high temperature of 350°C, and at the same time, pass hot air at 150°C into the greening cylinder; greening for 3 minutes;

[0084] ④, cooling, the tea leaves after step ③ is finished are put into a cooling device and cooled to 20°C;

[0085] ⑤, kneading, put the cooled tea leaves in step ④ into a kneading device and knead them into strips under pressure;

[0086] ⑥, dehumidification, put the tea leaves kneaded in step ⑤ into the dehumidification device, and remove 25% of the internal moisture of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com