Solid bean paste and preparation method and use method thereof

A production method and watercress technology, applied in the field of watercress, can solve the problems of limited use range, difficulty in mastering cooking time and cooking temperature, affecting the taste of ingredients, etc., and achieve the effects of improving appearance, improving quality and edible taste, and improving cooking range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

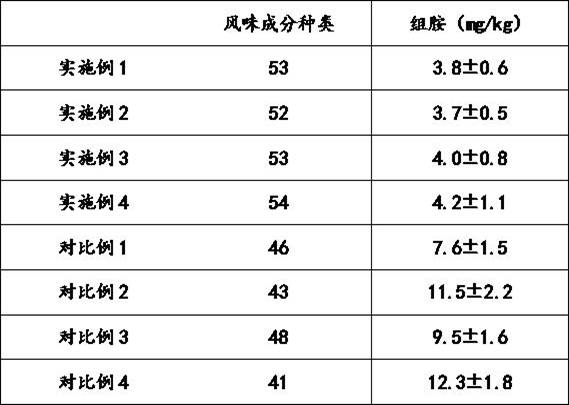

Examples

Embodiment 1

[0023] The content of each component in the solid watercress is calculated in parts by weight: 80-100 parts of watercress, 20-30 parts of fermented watercress, 4-6 parts of monosodium glutamate, 3-5 parts of spices, 4-6 parts of white sugar, anti-caking 0.5 to 0.8 parts of the agent.

[0024] A method for preparing solid watercress, the method comprising the following steps: S1, pulverize and grind the fermented Pixian watercress into tiny particles with a pulverizer or a colloid mill, and the particle size of the small particles is 100-200 S2, uniformly mixing the tiny particles obtained in step S1 with the juice in the fermentation process, wherein the mixing ratio of the tiny particles to the juice is 2:1; S3, drying, drying the mixed material through a fluidized bed, Improve the quality of the drying environment and improve drying efficiency; S4, grind the dried solid into powder, and grind the dried solid to 60-100 mesh; S5, mix the ground powder with monosodium glutamate...

Embodiment 2

[0026] The content of each component in the solid watercress is calculated in parts by weight: 85 parts of watercress, 25 parts of fermented watercress, 4 parts of monosodium glutamate, 4 parts of spices, 4 parts of white sugar, 0.6 parts of anticaking agent,

[0027] A method for preparing solid watercress, the method comprising the following steps: S1, pulverize and grind the fermented Pixian watercress into tiny particles with a pulverizer or a colloid mill, and the particle size of the small particles is 100-200 S2, uniformly mix the tiny particles obtained in step S1 with the juice in the fermentation process, wherein the mixing ratio of the tiny particles and the juice is 3:1, the stirring time is 30min, the temperature during the mixing and stirring process is 24°C, and Mix evenly; S3, dry, dry the mixed material through a fluidized bed, the drying temperature is 30-38°C, and the drying time is 2-3h, so as to improve the quality of the drying environment and improve the ...

Embodiment 3

[0029] The content of each component in the solid watercress is calculated in parts by weight: 80 parts of watercress, 30 parts of fermented watercress, 6 parts of monosodium glutamate, 5 parts of spices, 4 parts of white sugar, and 0.6 parts of anticaking agent.

[0030] A method for preparing solid watercress, the method comprising the following steps: S1, pulverize and grind the fermented Pixian watercress into tiny particles with a pulverizer or a colloid mill, and the particle size of the small particles is 100-200 S2, uniformly mixing the tiny particles obtained in step S1 with the juice in the fermentation process, wherein the mixing ratio of the tiny particles and the juice is 4:1, the stirring time is 30min, the temperature during the mixing and stirring process is 24°C, and Mix evenly; S3, dry, dry the mixed material through a fluidized bed, the drying temperature is 30-38°C, and the drying time is 2-3h, so as to improve the quality of the drying environment and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com