Ceramic heating body as well as core and atomizer utilizing ceramic heating element

The technology of a ceramic heating body and a ceramic body is applied in the field of electronic cigarettes, which can solve the problems of burning oil-conducting cotton, poor experience, affecting taste, etc., and achieve the effects of preventing oil frying, good taste, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

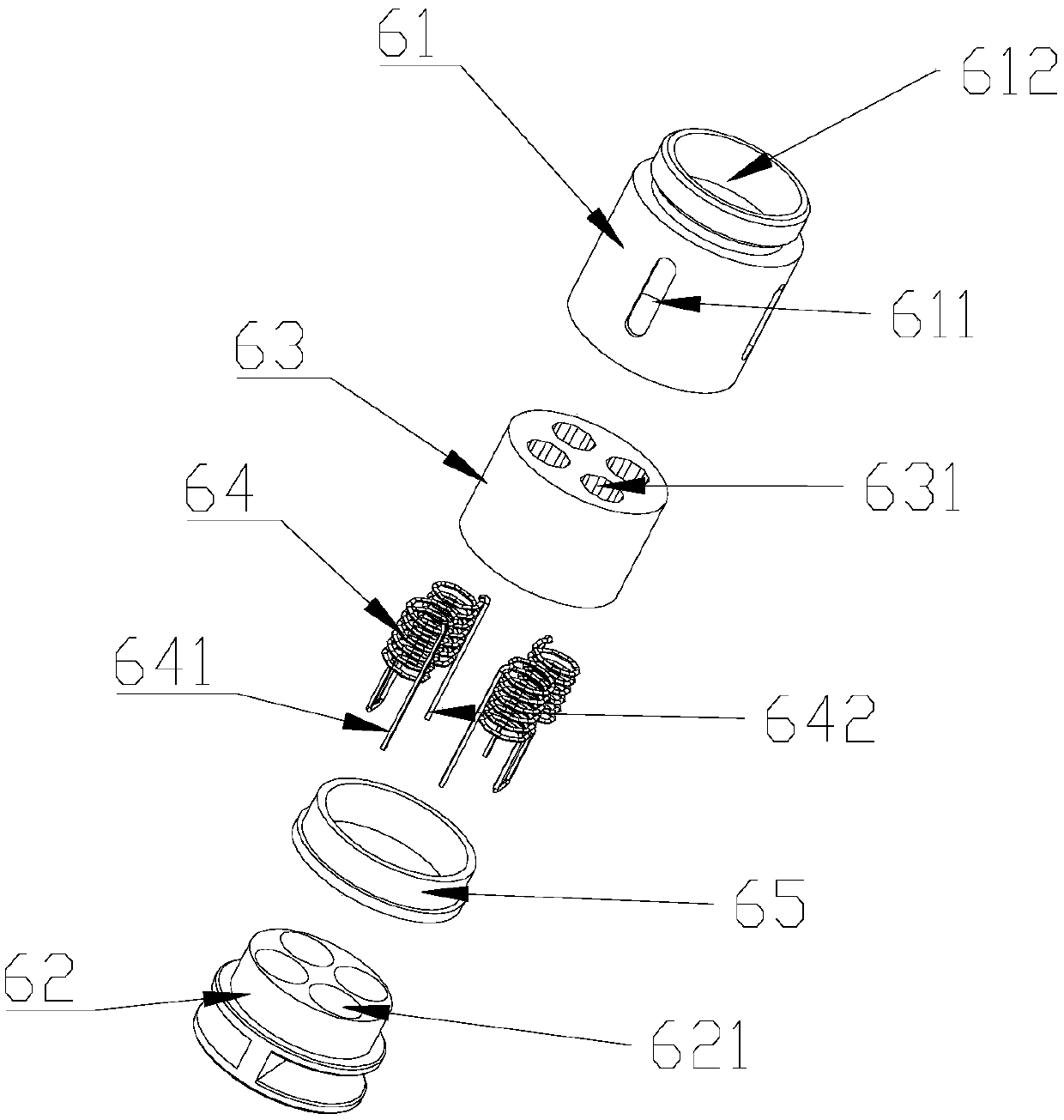

[0037] see Figure 4-5 As shown, the number of the heating element 64 is one, and the heating element 64 is a spiral ring structure. center, and the air intake passage 631 is gourd-shaped, and the heating element 64 is molded into the air intake passage 631.

Embodiment 2

[0039] see Figure 6 As shown, the number of the heating element 64 is two, the heating element 64 is a plate-shaped structure, the vertical projection of the heating element 64 is an open square, and the number of the air inlet channel 631 is one, and the air inlet channel 631 is arranged on the ceramic body 63, and the air intake passage 631 is a square, and the heating element 64 is molded into the air intake passage 631.

Embodiment 3

[0041] see Figure 7 As shown, the number of the heating element 64 is two, the heating element 64 is a plate-shaped structure, the vertical projection of the heating element 64 is an open regular hexagon, the number of the air intake channel 631 is two, and the air intake channel 631 surrounds The center of the ceramic body 63 is evenly distributed, and the air intake channel 631 is a regular hexagon, and the heating element 64 is molded into the air intake channel 631 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com