Patents

Literature

85results about How to "Shorten frying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ready-to-eat flavored fish skin and preparation method thereof

The invention provides ready-to-eat flavored fish skin and a preparation method thereof. The preparation method comprises the following technology steps: (1) macerating fish skin in wine: adding an edible alcohol solution of which the mass is 20-40% as much as the mass of the fish skin and of which the volume concentration is 60-90% to pretreated fish skin; uniformly stirring the pretreated fish skin and the edible alcohol solution so as to obtain a mixture; and placing the mixture in a sealing manner at a room temperature for 30-60 minutes, and then draining the edible alcohol solution so as to obtain wine-macerated fish skin; (2) preserving the wine-macerated fish skin: adding preserving materials to the wine-macerated fish skin obtained in the step (1), and uniformly stirring the preserving materials and the wine-macerated fish skin so as to obtain a new mixture; and preserving the new mixture in a sealing manner at the temperature of 4-15 DEG C for 4-12 hours so as to obtain preserved fish skin; (3) baking the preserved fish skin: baking the preserved fish skin obtained in the step (2) at the temperature of 50-70 DEG C for 20-50 minutes, after baking, cooling the baked fish skin to be room temperature, and then processing the cooled fish skin into slices so as to obtain dried fish skin slices; (4) deep-frying the dried fish skin slices; and (5) removing oil from the deep-fried fish skin slices, seasoning the dried fish skin slices after oil removal, and packaging the seasoned dried fish skin slices. According to the method disclosed by the invention, original color and original nutrition of the fish skin can be reserved to the maximum extent, the mouth feel and the preservation property are improved, and the processing technology is simple and environmental-friendly.

Owner:SICHUAN UNIV

Method for producing cassava modified starch for wrapping fried foods

InactiveCN102363636AReduce fuel consumptionShorten frying timeFood coatingFood shapingCassava (food)Citric acid

The invention discloses a method for producing modified starch for wrapping fried foods. In the method, cassava starch is used as a raw material, phosphorus oxychloride is used as a crosslinking agent, citric acid is used as an esterifying agent, a wet-process crosslinking-esterification-granulation-high-temperature drying-water returning chemical and physical modification process route is adopted, and multiple modification methods are used for preparing the modified starch for wrapping fried foods. In the invention, a technical process of combining a wet process and a dry process is adopted,the grain form of the starch is changed by a physical method, advantages complementation is realized, and the process flow is simple and applicable. The modified starch has the characteristics of high high-temperature expandability, high stability, high gelatinous property, high film forming property and the like; the use performance of the starch is improved; and the modified starch can improve the appearance, color and mouthfeel of fried food products and increase the tenderness-keeping and juice-retaining properties of products. Meanwhile the modified starch can reduce the used amount of athickening agent, reduce cost and improve the product yield.

Owner:广西农垦明阳生化有限公司

Milk-fragrance pleurotus eryngii crisp chip and preparation method thereof

InactiveCN103461965AThe liquid composition is uniformThe composition of the immersion liquid is consistentFood preparationSugarPolyphenol

The invention discloses a milk-fragrance pleurotus eryngii crisp chip and a preparation method thereof. The milk-fragrance pleurotus eryngii crisp chip comprises the following raw materials in parts by weight: 10-20 parts of pleurotus eryngii sheet, 1-2 parts of milk powder, 2.5-5 parts of white granulated sugar, 0.5-1 part of citric acid, 0.025-0.05 parts of tea polyphenol, and 6-12 parts of purified water. The preparation method comprises the steps of raw material treatment, impregnation, dehydration, vacuum frying, deoiling, cooling, packing and the like. The milk-fragrance pleurotus eryngii crisp chip has the characteristics of being appropriately fragrant, soft and crisp, has supplement of more nutrient substances and beneficial nourishing of pleurotus eryngii, is uniform in milk fragrance, appropriately acid and sweet, fragrant, crisp, tasty, and convenient to carry and eat, and is more appropriate for carrying and eating of travel and field operation people. The milk-fragrance pleurotus eryngii crisp chip is simple in preparation method and controllable in quality, can be massively produced, and has a better market prospect.

Owner:徐州绿之野生物食品有限公司

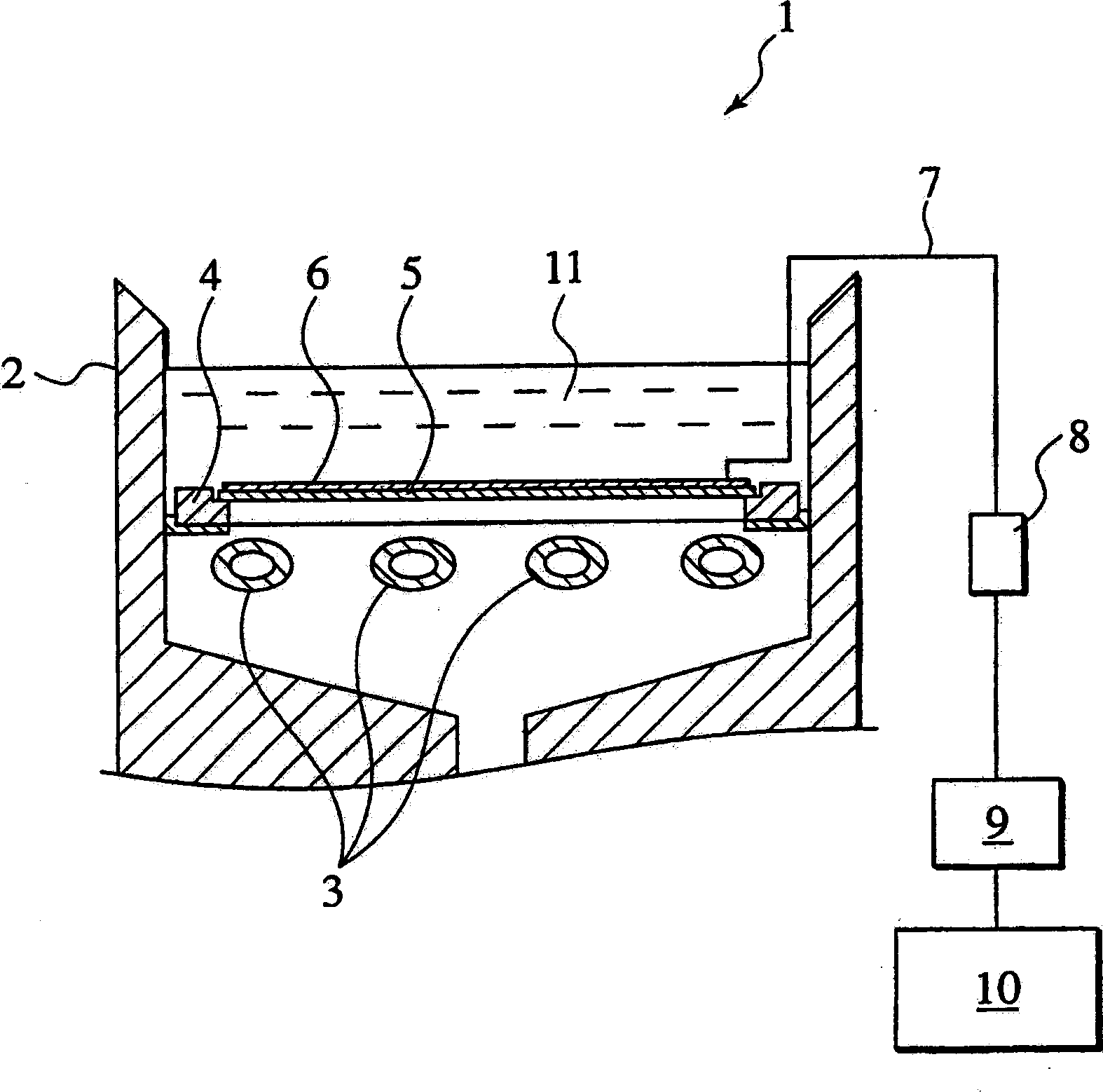

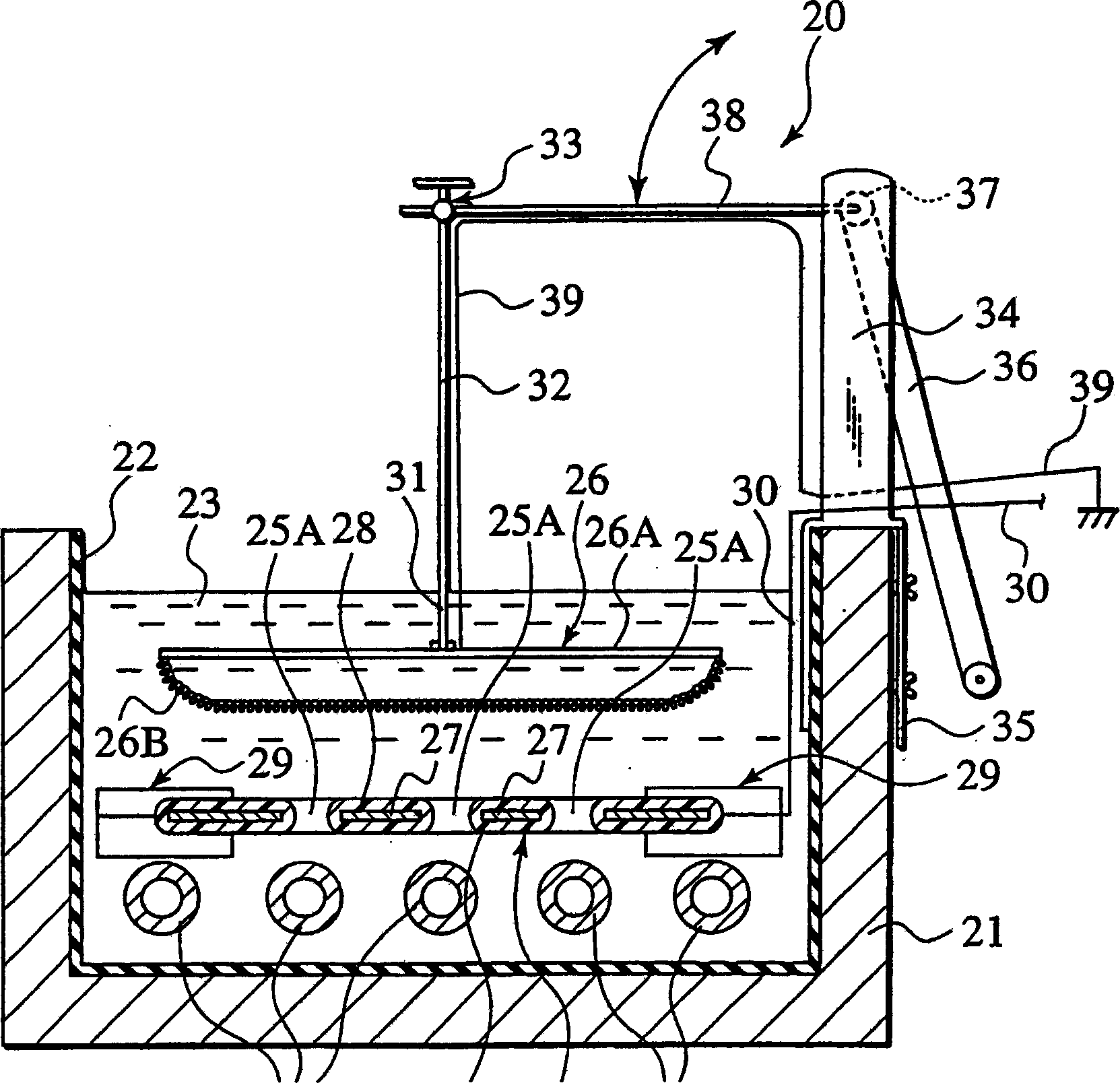

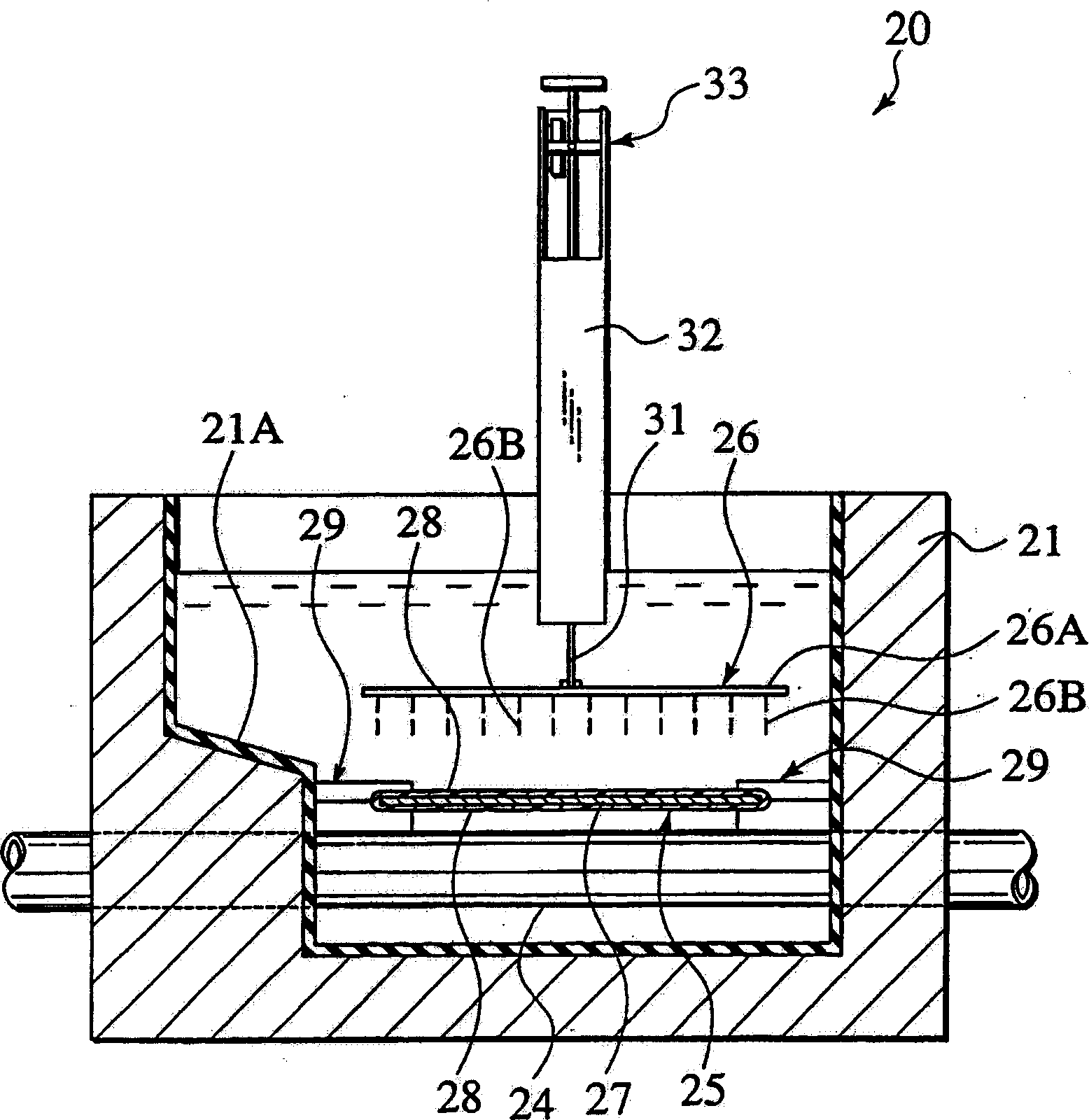

Fryer

InactiveCN1484508AImprove securityImprove utilization efficiencyWater-boiling vesselsDeep fat fryersPower flowEngineering

An electrode unit 25 applied with a high voltage and a grounded earth plate 26 are disposed in an oil bath 21 in a mutually opposed relationship, and an electric field shielding layer 22 made of insulation material is disposed so as to surround a frying region between the electrode unit and the earth plate 26, with the electrode unit 25 being applied with the high voltage to create a high-voltage weak current in the frying region. For this reason, a safety of a user can be enhanced, permitting the high-voltage weak current to afford a preferable influence to food material.

Owner:超级厨具株式会社

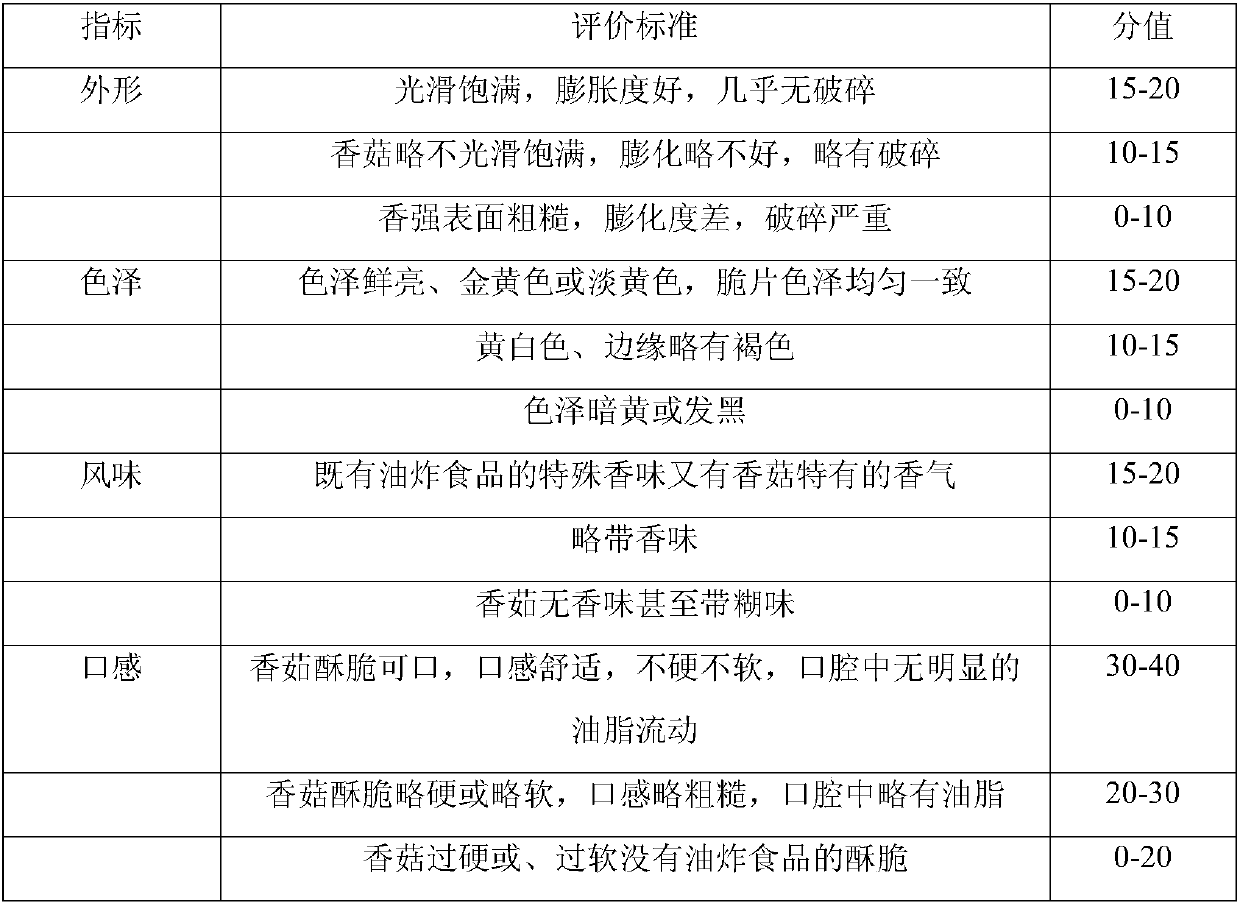

Processing method of shiitake mushroom crispy chips

InactiveCN107751981AIncrease the fragranceInhibitory activityFood ingredient functionsFlavorShiitake mushrooms

The invention belongs to the technical field of food processing and in particular relates to a processing method of shiitake mushroom crispy chips. The processing method comprises the following steps:preparing materials, protecting color, curing, immersing, quickly freezing, carrying out oil frying in vacuum and removing oil. According to the shiitake mushroom crispy chips prepared by the processing method, a color protection technology and hot soup are matched with spices with a certain ratio to prepare the shiitake mushroom crispy chips, the brittleness reaches 3400g, the moisture content is low and is only 1.3 percent and the oil content is 23.5 percent, so that the crispiness of the shiitake mushroom crispy chips is extremely ensured; the shiitake mushroom crispy chips have a smooth and full appearance, good expansion degree, are hardly broken, have bright color and luster and are golden yellow or light yellow; the crispy chips have uniform and consistent color and luster, have aspecial flavor of oil-fried foods and also have a special aroma of shiitake mushrooms; and the shiitake mushrooms are crispy and palatable, have a comfortable mouthfeel and are neither hard nor soft,and no obvious oil flows in an oral cavity.

Owner:贵州省印江自治县梵净山生态菌业有限公司

Processing method for reducing fat content of fried potato cakes

The invention discloses a processing method for reducing the fat content of fried potato cakes. The processing method comprises the following steps of: mixing wheat flour, gluten protein powder and sodium tripolyphosphate to prepare a film coating agent of potato cakes; quickly freezing a single coated potato cake and then frying; deoiling and then quickly freezing for the second time. The invention can effectively reduce the fat content of the fried potato cakes and improve the sensory quality of products.

Owner:福建省新润食品有限公司

Fried minced fillet product and preparation method thereof

InactiveCN104489765AEnhance layeringIncrease selenium contentSugar food ingredientsFood preparationIce waterSugar

The invention discloses a fried minced fillet product. The fried minced fillet product is characterized by comprising the following components: frozen minced fillet, silver carp meat, rice, ice water, cornstarch, salad oil, fresh egg white and seasonings. The invention further discloses a preparation method of the fried minced fillet product. The fresh silver carp meat is added, thus the layering sense of the product is improved, the fish smell is stronger, and the meat quality is more tender; after adding the selenium-enriched rice, on one hand, the selenium content in the product is increased, and the product is more nutrient; on the other hand, the cereals and the minced fillet are reasonably matched, and dietary nutrition is balanced; the used fat is soybean oil, and the unsaturated fatty acid content is increased compared with the way of adding fats in the traditional minced fillet product; low-temperature drying frying is adopted, white granulated sugar is replaced by glucose and xylose, and the frying time is shortened and the frying temperature is lowered under the condition of high vacuum degree, thus the product is easier to colour.

Owner:SHANDONG HELI AGRI DEV

Processing method of dried crispy fishes

InactiveCN107751848AImprove qualityIncrease tightnessFood ingredient as antioxidantFood ingredient as taste affecting agentDried fishDistillation

The invention discloses a processing method of dried crispy fishes. The processing method of the dried crispy fishes is characterized by comprising the following steps: (1), carrying out washing, namely sorting trash fishes, putting the sorted fishes into clean water, adding treatment liquid so as to carry out dipping, removing viscera, and carrying out washing; (2), carrying out pickling, namelyuniformly mixing a pickling material with the washed fish meat, containing the mixture in a sealed container, and carrying out pickling ; (3), carrying out marinating, namely immersing the pickled fishes in a marinade, and carrying out ultrasonic oscillation; (4), carrying out steaming, namely roasting the marinated fishes, putting the baked fishes on a distillation layer of a steamer, and carrying out steaming; (5), carrying out oil-frying, namely brushing surfaces of the steamed fishes with camellia seed oil, brushing inner side and outer side of the steamed fish meat with seasoning paste, carrying out baking in an oven, and carrying out oil-frying by immersing the baked fishes in oil; and (6), carrying out sealed packaging, namely performing ultraviolet lamp irradiation on the oil-friedfishes so as to carry out sterilization, and filling nitrogen into packages so as to obtain the dried crispy fishes.

Owner:蚌埠市徽吉星农业科技农民专业合作社

Application of L-arabinose to coloring agent of fried minced fillet product

ActiveCN103948016AGood colorUniform colorFood ingredient functionsFood preparationBiotechnologyGolden syrup

The invention relates to the technical field of a food coloring agent, and in particular relates to an application of L-arabinose to a coloring agent of a fried minced fillet product. The application comprises the following steps: feeding the coloring agent containing the L-arabinose into oil with the weight being equal to that of the coloring agent; preheating the mixture and frying into the caramel color; feeding 5-10 times of water to prepare golden syrup; and putting the minced fillet product into the syrup to enable the surface of the product is evenly stained with the syrup, and frying. A caramelization reaction is carried out, and the colored syrup exists on the coating of the surface of the minced fillet product, so that the minced fillet product has attractive golden yellow color after being fried; the coloring agent not only is good in coloring effect and even in coloring, but also has small possibility of generating carcinogenic substances such as acrylamide due to low temperature, short time and rapid coloring in the frying process.

Owner:SHENGQUAN HEALTANG CO LTD

Special coloring agent of deep-fried minced fillet type products

ActiveCN103960650AAttractive golden colorPlay a synergistic roleSugar food ingredientsFood ingredient functionsBiotechnologyArabinose

The invention relates to the technical field of food coloring agents, and in particular relates to a special coloring agent of deep-fried minced fillet type products. The coloring agent is prepared from the following components in parts by weight: 0.5-99.5 parts of L-arabinose, 0.5-99.5 parts of D-xylose and 0-60 parts of glucose. A preparation method of the coloring agent comprises the following steps: the L-arabinose, the D-xylose and the glucose are uniformly mixed, then are added into oil with weight equal to that of the mixture and are preheated for hot frying to obtain caramel; 5-10 times of water is added to prepare gold-yellow syrup; minced fillet type products are put into the syrup to uniformly cover the surfaces of the products with the syrup and then are fried. Therefore, the gold-yellow color of the deep-fried minced fillet type products is attractive, and the taste of the deep-fried minced fillet type products cannot be affected; in a deep-frying process, the temperature is low, the time is short, and the coloring speed is high, so that cancerogenic substances such as acrylamide are almost not generated.

Owner:SHENGQUAN HEALTANG

Oil pressing technology and application of high-oleic acid peanuts

InactiveCN109181841AReduce cumbersomeEnhance aroma substancesFatty-oils/fats productionEdible oils/fatsMaillard reactionPyrene

The invention relates to an oil pressing technology and an application of high-oleic acid peanuts. The peanuts are preprocessed with microwaves to reduce the tediousness in the production process of strong fragrant peanut oil, the fragrance degree can be controlled by controlling the microwave treatment time, a high temperature generated by the microwaves increases fragrant substances generated bya Maillard reaction, and the microwaves make oil have a good flavor, and avoid a burnt smell caused by traditional frying; the microwave treatment destroys the physical structure of the peanuts, so oil molecules can be easily squeezed out; the microwave pretreatment utilizes energy generated by high-speed movement of polar molecules in the molecules, so the purposes of easy uniform heating, shortening of the frying time, no burnt smell and reduction of the content of benzo(a)pyrene in the oil are achieved; and the microwave pretreatment avoids the drying treatment of the peanut raw material,so the energy consumption is reduced.

Owner:SHANDONG LUHUA GROUP

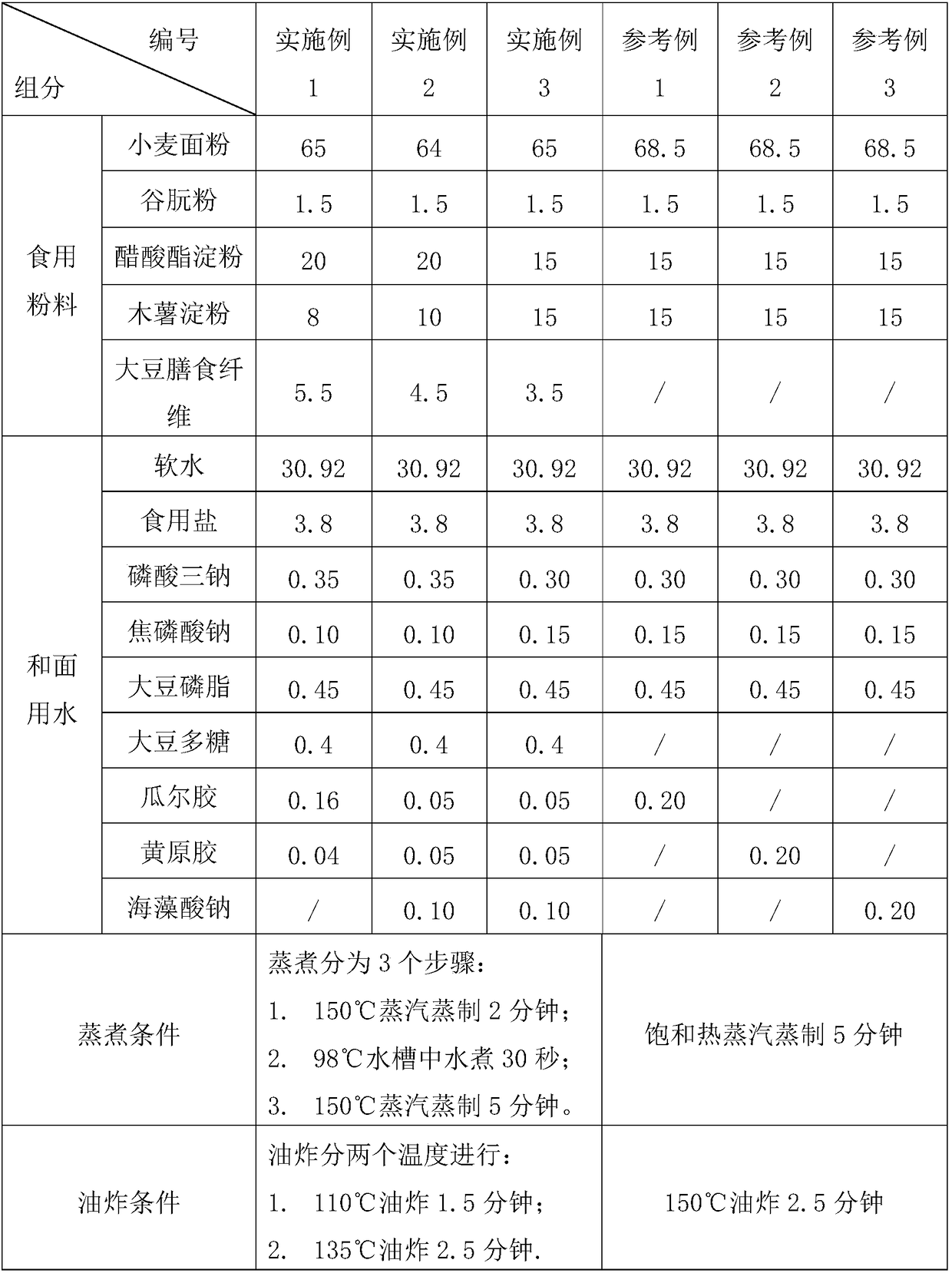

Oil-fried Udon noodles and processing method thereof

InactiveCN108208578AExcellent extension performanceExcellent pasting propertiesFood scienceWater solubleWater use

The invention discloses a processing method of oil-fried Udon noodles. The processing method of the oil-fried Udon noodles comprises the following steps of uniformly dissolving edible salt, compound phosphates, an emulsifier, a thickening agent and water-soluble soybean polysaccharides in weakly alkaline soft water so as to obtain water used for making dough; adding the water used for making doughinto edible flour, and carrying out vacuum stirring so as to make dough; performing 1-time compounding on the dough by utilizing a composite rolling machine so as to obtain a dough band, and performing curing treatment on the dough band; rolling the dough band by using a rolling machine so as to obtain dough sheet; cutting the dough sheet into stripes by using a cutter, and carrying out preliminary shaping by performing knurling by using a baffle so as to obtain noodles; sending the shaped dough noodles into a staged steaming box via a conveyor belt; stretching the steamed noodles, carrying out quantitative cutting, and carrying out oil-frying in a pan so as to carry out dewatering, and thus, oil-fried noodle blocks are prepared. The noodles are oil-fried by adopting two-stage oil-frying,wherein the first stage is low-temperature frying and the second stage is high-temperature frying. By optimizing raw material formula and processing method, the oil-fried Udon noodles prepared according to the processing method are chewy, soft and smooth in taste, as well as good in tenacity. And thus, a new idea and direction of noodle product industry is provided. The oil-fried Udon noodles andthe processing method thereof have wide market prospects and market benefits.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

A production process of ultrasonic-assisted freezing and vacuum-frying edible mushrooms

ActiveCN103892255BEasy to removeAvoid affecting heat transfer efficiencyFood dryingFood ultrasonic treatmentVacuum pressureUltrasonic assisted

The invention relates to an ultrasonic-assisted freezing and vacuum frying production process of edible fungi. The process is used for solving the problem that no relatively perfect pre-drying technique for the vacuum low-temperature frying of the edible fungi exists at present. The process disclosed by the invention comprises the following steps: (1) selecting edible fungus raw materials; (2) carrying out ultrasonic pre-drying at the ultrasonic frequency of 28kHz, at the ultrasonic power of 80-120W, under the vacuum pressure of 5-10kPa and at the temperature of 20-45 DEG C till the water content is 20-30%; (3) carrying out quick-freezing at the temperature of minus 50-minus 30 DEG C till the edible fungi are completely frozen; (4) carrying out vacuum frying for 5-20 minutes under the vacuum pressure of 0.1-5kPa and at the oil temperature of 80-90 DEG C; (5) carrying out vacuum deoiling under the vacuum pressure of 0.1-5kPa; (6) carrying out seasoning; (7) carrying out inert gas filling packaging to obtain finished products. The process disclosed by the invention is capable of stably maintaining the shape and the color of the fried edible fungi.

Owner:ZHEJIANG FORESTRY ACAD

Preparation method of expanded popcorn and product thereof

The invention provides a preparation method of expanded popcorn. The method comprises the following steps: selecting materials; removing impurities; grading corn kernels through screening, wherein the corn kernels are divided into 2-3 grades according to sizes of the corn kernels; boiling: putting impurity-removed corn kernels with uniform sizes in the same grade in a pot, adding water of which the weight is 1.5-2.5 times of the weight of the raw materials, and heating and boiling the water for 120-150 minutes; draining the boiled corn kernels, and drying the corn kernels until the water content of the corn kernels is reduced to 10.5-14%; expanding the obtained dry corn kernels; screening the corn kernels; putting the screened corn kernels in oil with the temperature of 180-190 DEG C for frying for 55-65 seconds; flavoring the fried corn kernels; and carrying out microwave drying on the flavored corn kernels until the water content of the corn kernels is reduced to be within 3%, thereby obtaining the expanded popcorn. The method provided by the invention lowers the temperature, shortens the time, reduces the nutrient loss, reduces the energy consumption and reduces the production cost, the product has good mouthfeel, and the shelf life is prolonged.

Owner:HUNAN AGRICULTURAL UNIV

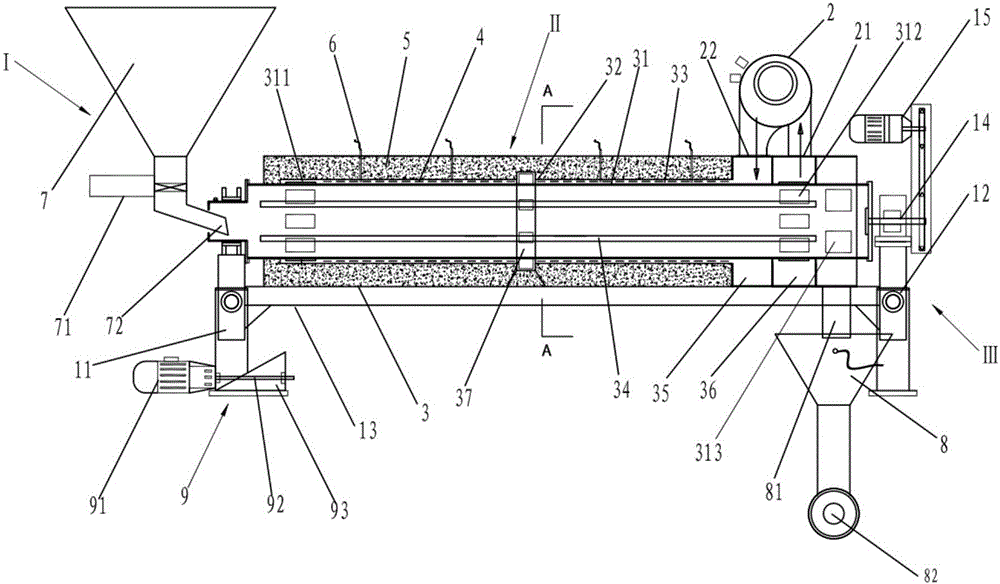

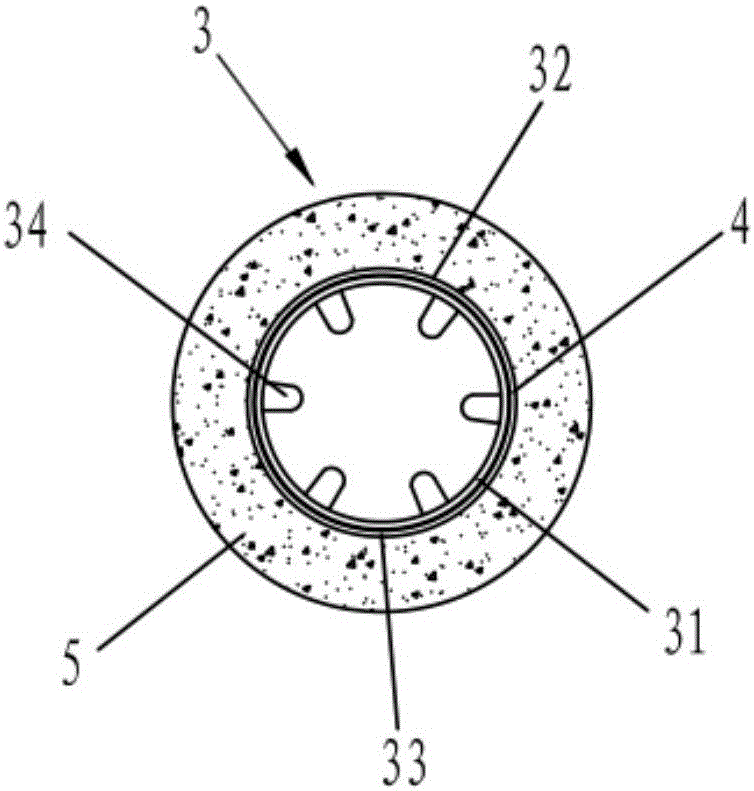

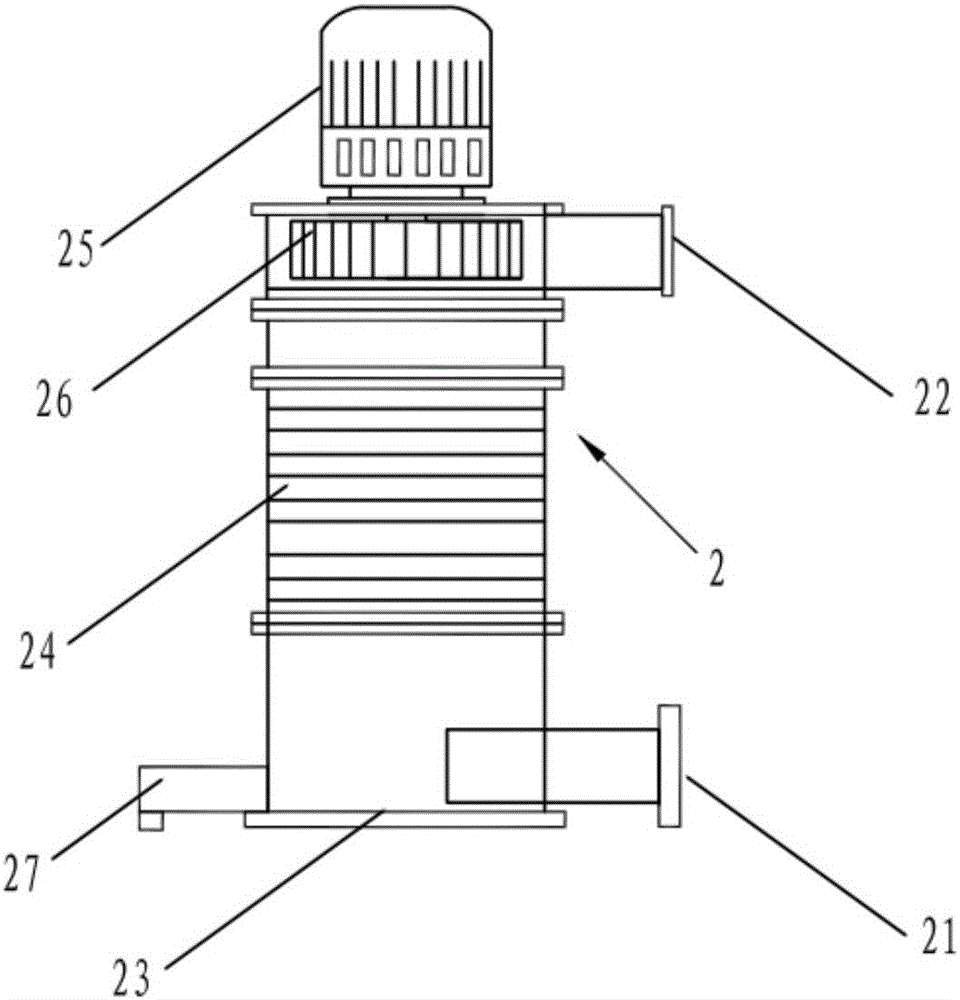

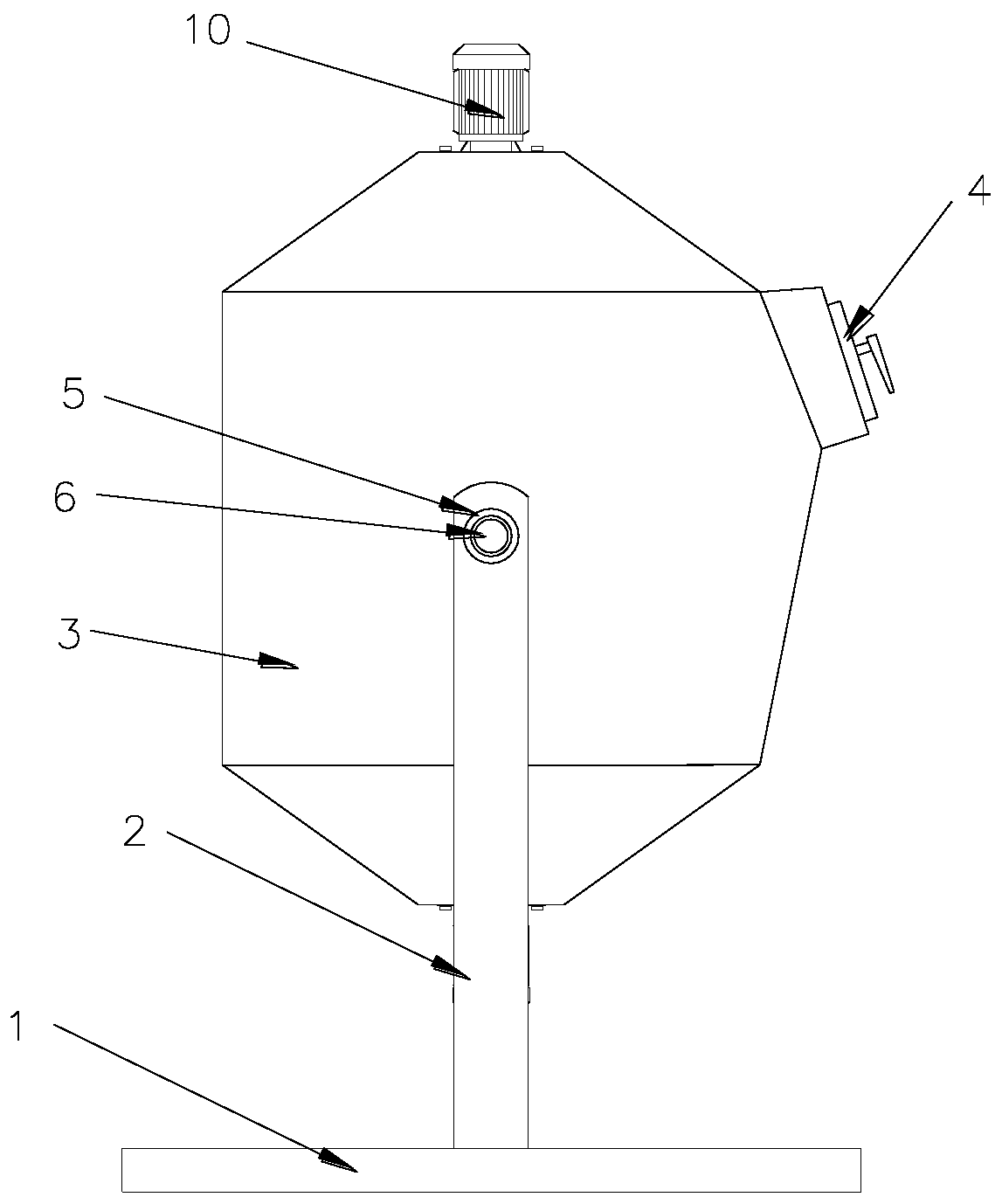

Continuous parching equipment

The invention relates to continuous parching equipment which comprises a rack, a feeding mechanism, a parching mechanism, a discharging mechanism and an oil stain separation and collection device. The parching mechanism is mounted above the rack, the feeding mechanism and the discharging mechanism are arranged at the feeding end and the discharging end of the parching mechanism respectively and communicated with the parching mechanism, and the parching mechanism comprises a roller and a heating element. The roller comprises an inner barrel and an outer barrel arranged outside the inner barrel in a sleeving mode, a closed air channel is formed between the inner barrel and the outer barrel, and the heating element is arranged in the air channel. An air inlet of the oil stain separation and collection device is communicated with the interior of the roller, an air outlet of the oil stain separation and collection device is communicated with the air channel, and high-temperature smoke generated in the roller is purified through the oil stain separation and collection device and then is subjected to secondary heating through the air channel to be guided back to the roller. In the seed parching process, cyclic utilization of heat is achieved, it is guaranteed that the equipment is free of emissions, the production environment can be clean, and the aims of saving energy and reducing emissions are achieved.

Owner:浙江宇清热工科技股份有限公司

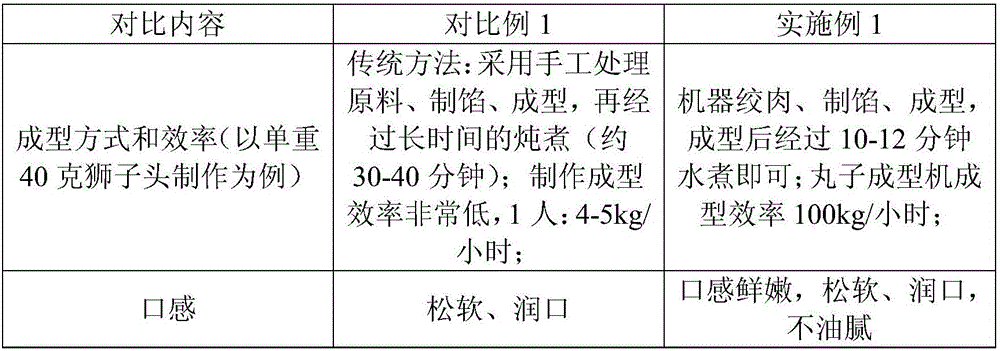

Large meatballs and preparation method thereof

InactiveCN105918920AImproved frying and coloring effectShorten frying timeFood scienceXyloseChemistry

The invention relates to the technical field of foods, and especially relates to large meatballs and a preparation method thereof. The large meatballs are prepared from the following raw materials: 20-30 parts of lean meat, 32-42 parts of marbled meat, 1-3 parts of gingers, 1-3 parts of chives, 7-13 parts of Chinese water chestnuts, 7-13 parts of ice water, 3-7 parts of egg liquid and 0.2-2 parts of potato starch. The large meatballs further comprise an accessory ingredient A or an accessory ingredient B; the accessory ingredient A comprises 0.1-0.5 part of baking soda and 0.5-2 parts of hydroxypropyl distarch phosphate; and the accessory ingredient B comprises 0.1-0.5 part of baking soda, 0.5-2 parts of hydroxypropyl distarch phosphate, 0.1-0.6 part of xylose and 0.2-1.2 parts of glucose. The preparation method comprises the following steps: mixing materials, shaping the mixture, and carrying out cooking. Moisture as well as fresh and tender taste of the meat used for making the large meatballs provided by the invention are better preserved during the processing steps, so that taste of the meat is prevented from being tenacious, hardening and roughening. The prepared large meatballs are fresh, tender, loose and soft in taste. The preparation method disclosed by the invention is simple, easy to operate and suitable for industrialized production.

Owner:SANQUAN FOOD

Method for processing frozen seasoning fish roe product

Provided is a method for processing a frozen seasoning fish roe product. The method comprises a step (1) of taking roes of fresh cods having undergone film removal and cleaning, or heating and stirring the frozen cod roes at 110-120 DEG C until the cod roes are unfrozen for standby application; a step (2) of adding the cod roes, water and seasoning according to a mass ratio of (50%-60%):(10%-20%):(20%-40%) into a stir-frying pot, wherein the seasoning is obtained by mixing light soy sauce, dark soy sauce, white sugar, salt, skipjack concentrated solution, fresh ginger juice and mirin according to a mass ratio of (6-8):(4-6):(15-18):(1-2):(0.1-0.5):(0.3-0.6):(0.5-1.0), heating the materials with stirring until the materials boil, and then adopting a programmed freezing mode to perform stir-frying; wherein the programmed freezing mode comprises the steps of first performing stir-frying for 8-15 min at 100-110 DEG C, then performing stir-frying for 15-25 min at 85-90 DEG C, and finally performing at 60-70 DEG C until the product is dry; and a step (3) of cooling, packaging, sterilizing and freezing the well stir-fried cod roes to obtain the frozen seasoning fish roe product. According to the method, the stir-frying time is shortened, production efficiency is improved, and the manufactured frozen seasoning fish roe product is excellent in flavor and nutrition and safe to eat.

Owner:兰溪市浙工大技术转移中心

Maltose red bean paste and preparation method thereof

InactiveCN107853544ARefreshing and pleasant tasteSmooth and delicate flavorFood ingredientsFlavorRed bean

The present invention discloses maltose red bean paste and a preparation method thereof. The red bean paste mainly comprises the following raw materials: raw bean paste, ultra-high malt syrup and modified starch. A weight ratio of the raw bean paste, ultra-high malt syrup and modified starch is 100:(60-100):(5-15). The ultra-high malt syrup is used to replace sucrose to stir-fry stuffing, the beanpaste is fresher and pleasant in mouthfeel, refreshing, smooth and delicate in flavor, also higher in stability, not easy to be aged and longer in shelf life, and can also reduce costs. In addition,a treatment method of adding trisodium phosphate and sodium hydroxide during bean soaking enables red beans to fully absorb water and be softened, and starch molecules to fully swell, and shortens bean soaking time, and can also enable anthocyanins in the red beans to be decomposed to produce a bean fragrance under an micro-alkaline condition. A mild bean cooking process of a primary cooking and asecondary cooking can reduce a bean breaking rate, enables red bean cells to be complete in tissues and liable to absorb sugar, shortens stuffing stir-frying time, and improves product quality and yield.

Owner:FUTASTE PHARM CO LTD

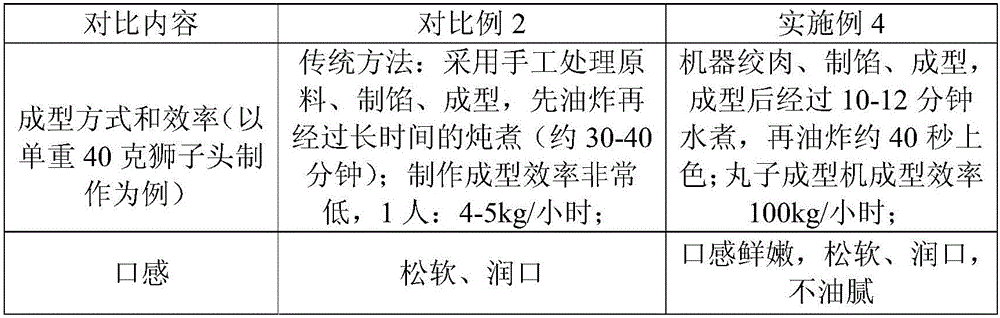

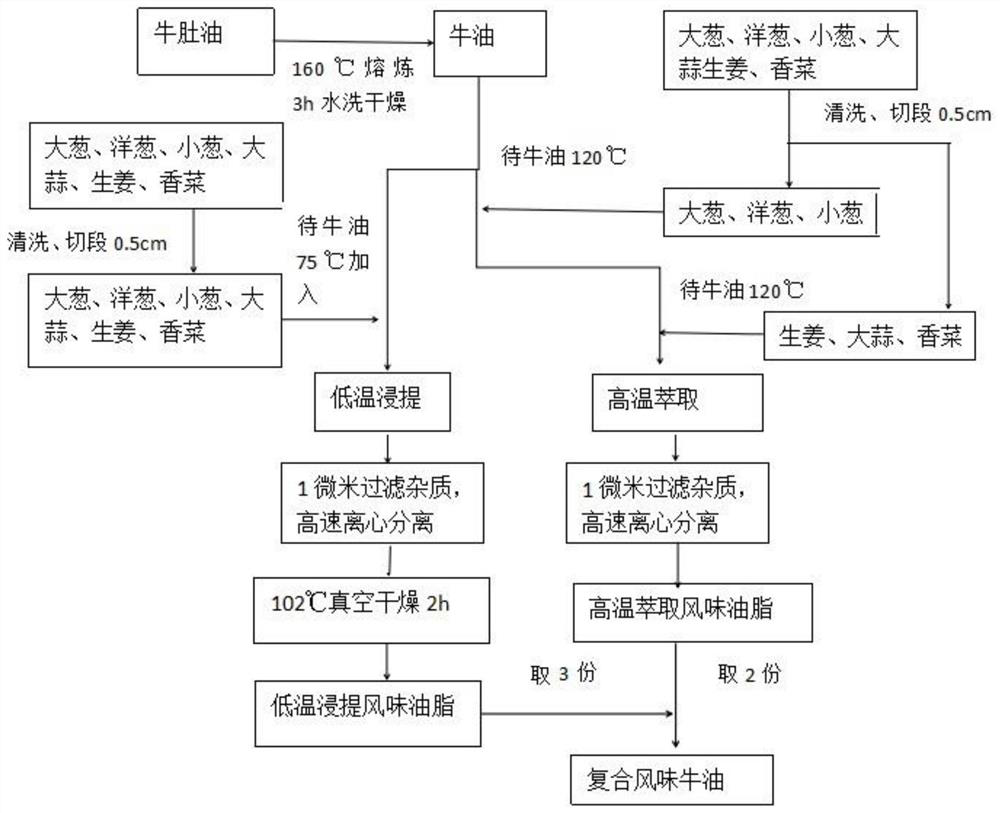

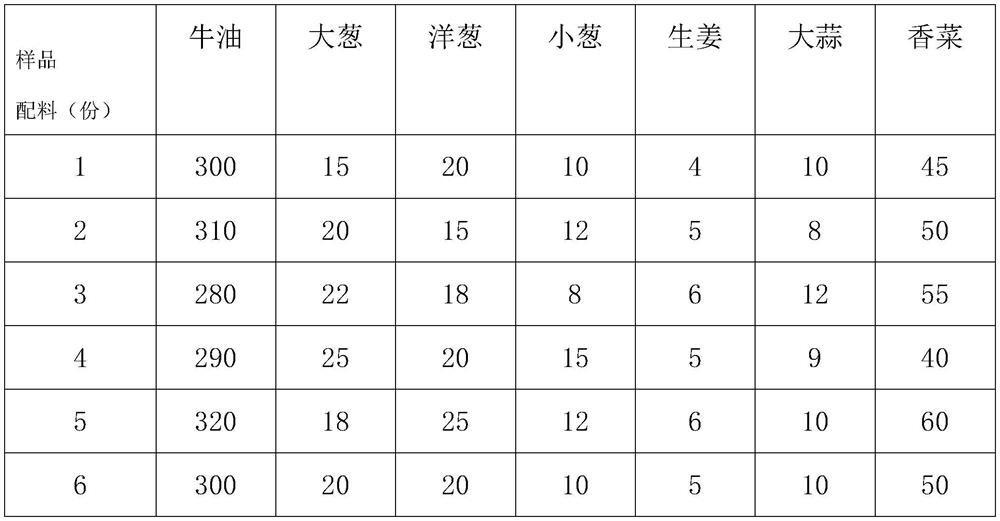

Composite flavor beef tallow and production process thereof

The invention discloses composite flavor beef tallow and a production process thereof. The composite flavor beef tallow is prepared by matching selected beef tallow with green Chinese onion, onion, shallot, ginger, garlic and caraway. The invention further provides a production process of the composite flavor beef tallow. The composite flavor beef tallow is prepared by adopting a low-temperature extraction technology and a high-temperature extraction technology. The composite flavor beef tallow increases the composite vegetable flavor of dishes, makes up the deficiency of flavor in the frying process of hotpot condiments and the like, improves the product yield, reduces the cost, saves resources, shortens making time, comprehensively reduces the frying cost by more than 25%, is used for frying the hotpot condiments and taking the hotpot condiments out of a pot, can further be used for frying crayfish, frying in a dry pot, seasoning spicy fish and the like, and the taste is convenient.

Owner:GUANGHAN HANGJIA FOOD CO LTD

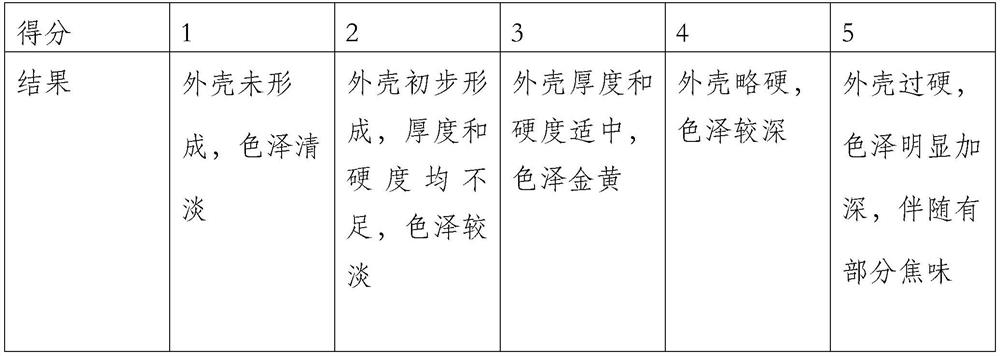

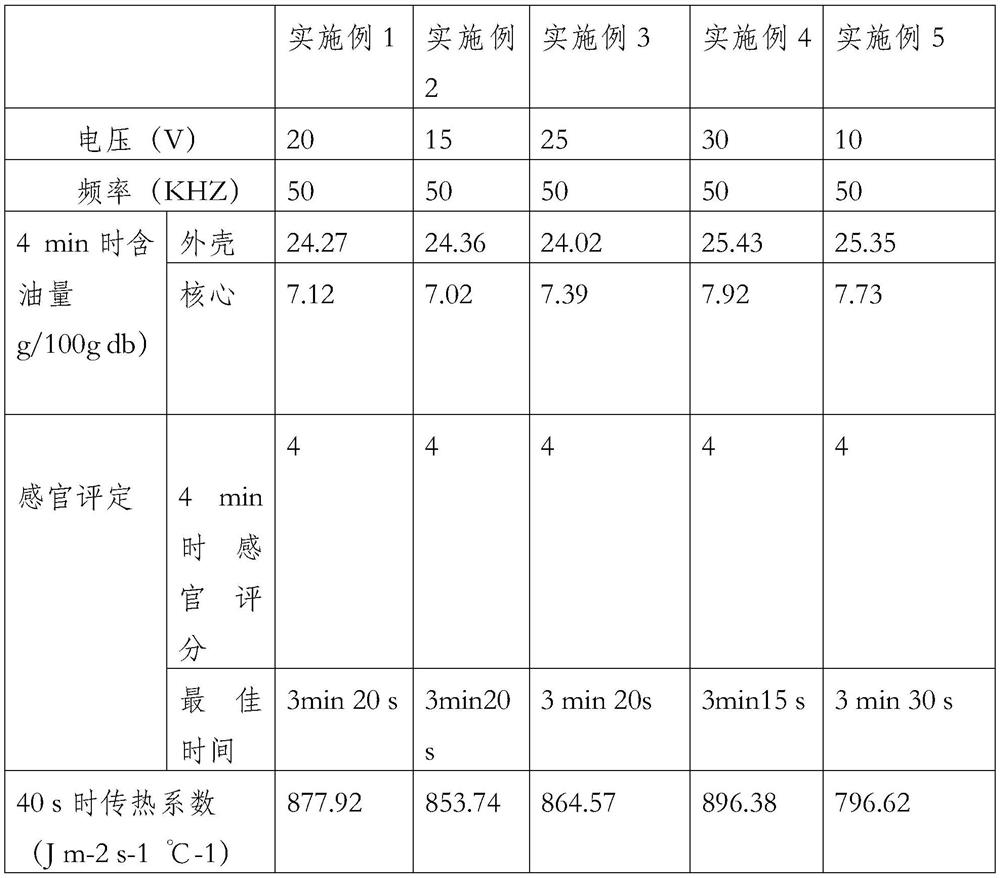

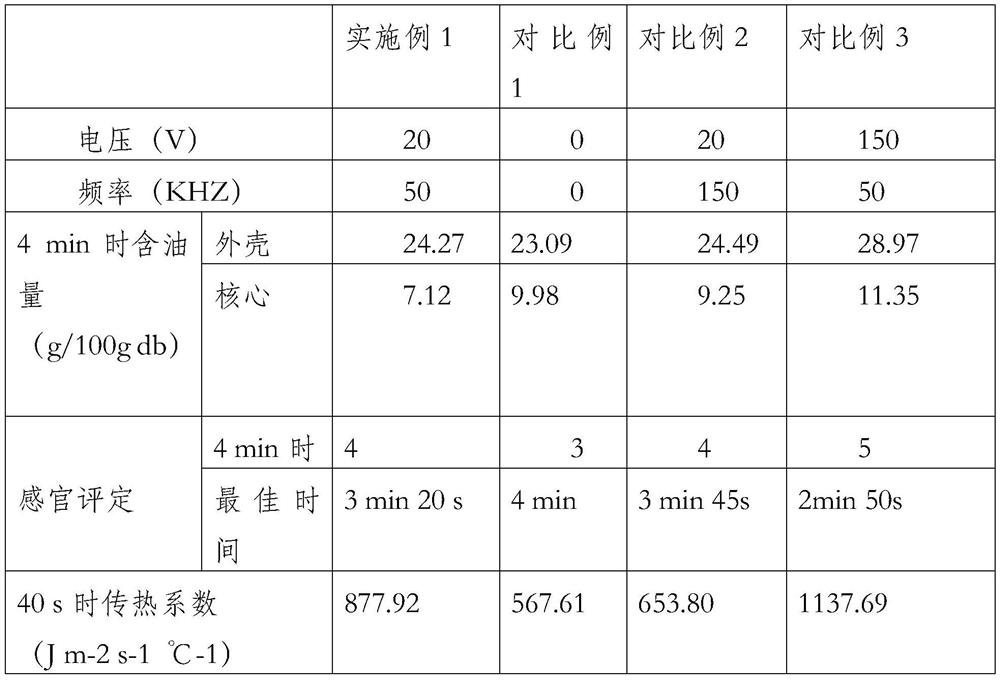

Moderate-intensity electric field treatment based method for reducing oil absorption amount of fried food

ActiveCN112890078AReduce splashPrevent Mutual AggregationFood electrical treatmentThermodynamicsEngineering

The invention discloses a moderate-intensity electric field based treatment method for reducing oil absorption amount of fried food. The method comprises the following steps: oil is heated, materials are added for frying treatment, and moderate-intensity electric field treatment is applied in the frying treatment process, wherein the voltage range of the electric field treatment is 5-100 V, and the frequency range of the electric field treatment is 1-100 KHz; and the frying treatment temperature is 120-200 DEG C. According to the moderate-intensity electric field treatment based method for reducing the oil absorption amount of the fried food, the uniform and strong moderate-intensity electric field is formed after parallel polar plates in a frying pan are powered on, and after the materials are put into the frying pan to be fried, an electric field can affect bubbles generated by the materials and prevent the bubbles from being mutually gathered, so that the heat transfer efficiency is improved, the frying time is shortened, and splashing of oil droplets is reduced; and meanwhile, rapid heat transfer also accelerates rapid formation of hardened shells on the surfaces of the materials, evaporation of internal water is further inhibited, and the oil absorption amount is reduced.

Owner:JIANGNAN UNIV

Instant peach gum puffing crisp chips and preparing method thereof

The invention discloses instant peach gum puffing crisp chips and a preparing method thereof. The preparing method comprises the following steps of peach gum pretreatment, mixing, injection molding shaping, deep frying puffing, cooling and packaging, wherein high-pressure and high-temperature and negative-pressure low-temperature continuous deep frying puffing is adopted in the step of deep frying puffing. According to the instant peach gum puffing crisp chips and the preparing method thereof, peach gum serves as the main raw material, the peach gum puffing crisp chips low in oil content, nutrient and healthy are prepared through high-pressure and high-temperature and negative-pressure low-temperature continuous deep frying puffing, and the prepared peach gum puffing crisp chips are especially unique in flavor and taste; in addition, due to the fact that the peach gum contains the functional factor arabinose which can assist in losing weight and reducing blood glucose, the health level of the deep-fried puffing product is greatly increased.

Owner:XIANGNAN UNIV

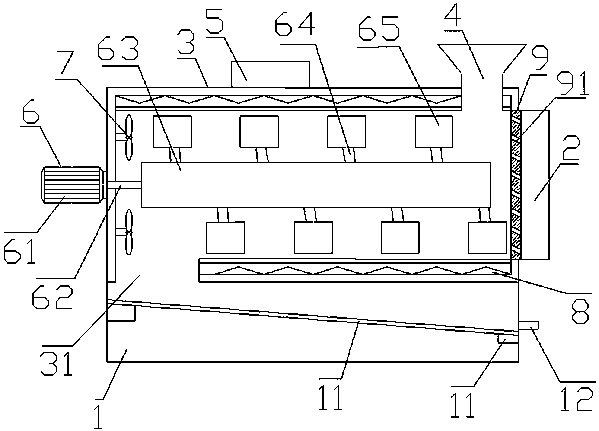

Production device and production process of fresh and crisp melon seeds

The invention discloses a production device and a production process of fresh and crisp melon seeds. The production device adopts an up-and-down turnover roller type structure, electric heating devices and stirring mechanisms are arranged on the top end and the bottom end of a roller, stirring blades of the stirring mechanisms also comprise long blades and short blades, and the long blades and theshort blades are connected with the electric heating device, melon seeds in the center and the edge of the roller bottom can be effectively turned over, so that the melon seeds in the roller body integrally, uniformly and quickly flow along with a stirring shaft; besides, the roller is turned over once every a period of time, so that the melon seeds in the roller are raised and fall back to the bottom of the roller, the melon seeds in the roller can be turned over and flow, the melon seeds can be more uniformly and fully heated in combination with the baking of an electric heating wire, and the probability of insufficient baking or excessive baking of the melon seeds is reduced; the overall quality of finished melon seeds is remarkably improved, and the obtained melon seeds are fresh, crispy and delicious; and the stir-frying mode of matching up-and-down rolling and stirring can enable the melon seeds to be stir-fried more quickly, so that the stir-frying time is shortened.

Owner:福州翁财记食品有限公司

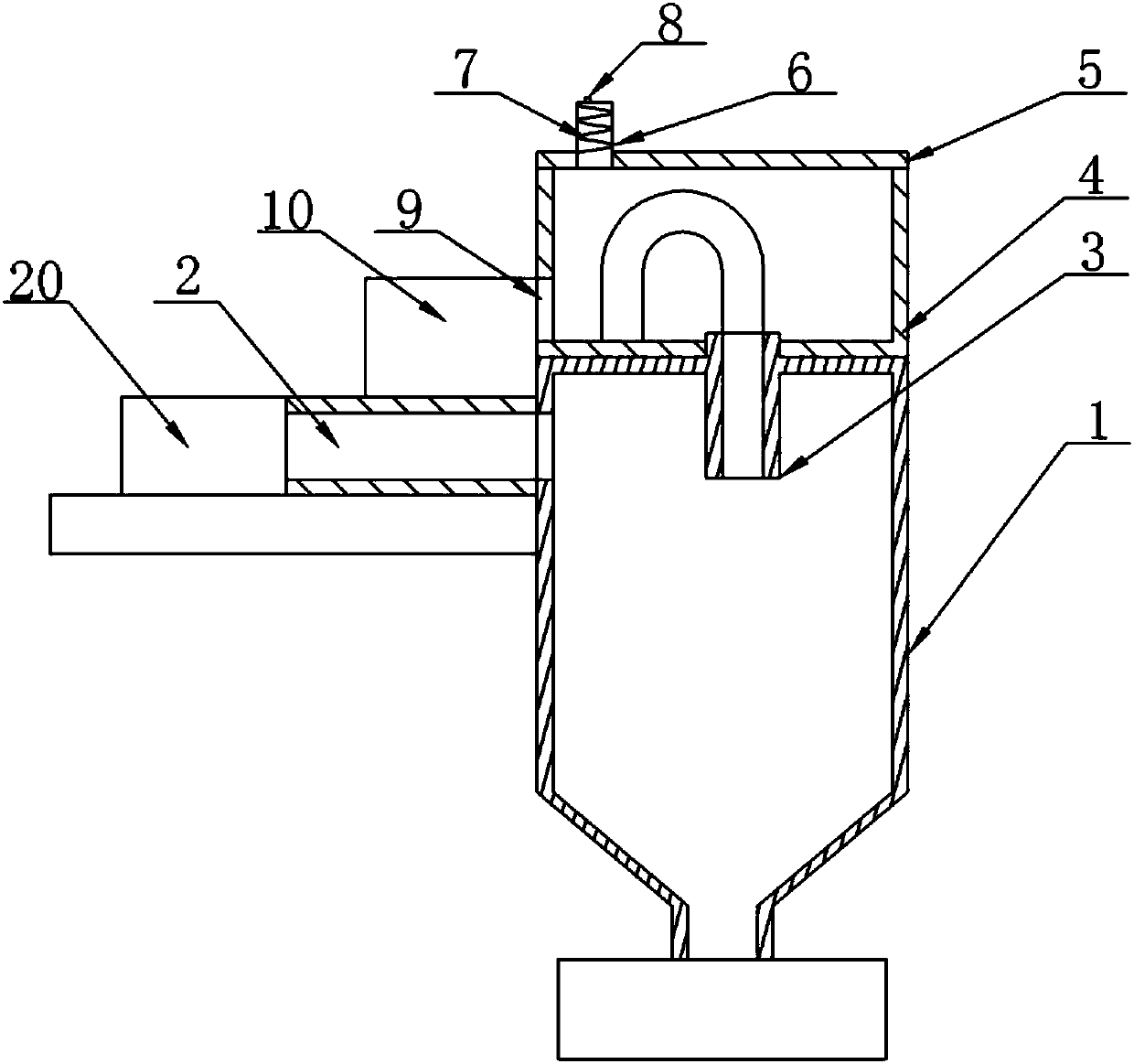

Tea leaf processing device

PendingCN107716437AQuality improvementResidue reductionPre-extraction tea treatmentTea dryingEngineeringTea leaf

The invention relates to the technical field of tea leaf processing and discloses a tea leaf processing device. The tea leaf processing device comprises a rack and a cyclone separator. The cyclone separator comprises a cylinder and a cone. The cone is provided with an opening. The cylinder is provided with an air inlet channel, and the cylinder is fixedly provided with an air outlet channel. A cleaning box is fixed to the cylinder and is provided with a U-shaped pipe. The cleaning tank is provided with a cover body and is provided with a first electromagnetic valve. A first pressure switch isarranged at the lower portion of the cover body. A water pipe is arranged at the upper portion of the cover body. The water pipe is provided with a second pressure switch, and a dewatering mechanism is arranged above the air inlet channel. The dewatering mechanism comprises a dewatering box and a motor, and the dewatering box is fixedly installed on the motor. The dewatering box is provided with awater outlet hole and is fixedly provided with a second electromagnetic valve. A discharging port is formed in a bottom plate of the dewatering box, and the discharging port is provided with a sliding plate and a discharging pipe. A V-shaped plate is provided with a spring, the spring is connected with a third pressure switch, and the air inlet channel is fixedly provided with an air heater. Thetea leaf processing device is simple in structure and capable of sufficiently cleaning tea leaves and removing pesticide and fertilizer residues on the surfaces of the tea leaves.

Owner:湄潭华山剑茗茶业有限公司

Five-spice cashew

InactiveCN108077865ARich tasteShorten frying timeFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentIcing sugarFlavor

The invention discloses a five-spice cashew. The five-spice cashew comprises the following raw materials in parts by weight: cashew kernels, flour, powdered sugar, salt, five spice powder, glutinous rice flour, corn flour and egg liquid. The five-spice cashew is prepared in the following steps: continuously baking the cashew kernels under low temperature; moving out; spreading to cool; fully stirring the powdered sugar, the salt and the egg liquid in parts by weight; uniformly mixing the flour, the five spice powder, the glutinous rice flour and the corn flour in parts by weight; coating the cooled cashew kernels with the egg liquid; then coating with the mixed powder; frying the cashew kernels coated with the powder for 1.5-3min through oil under the temperature of 150-170 DEG C; spreading to cool; then packing. According to the five-spice cashew, the cashew kernels are continuously baked under low temperature, and the oil frying time is reduced, so that the health is ensured; the cashew kernel surfaces are coated with sugar syrup and then is coated with mixed powder containing the flour and the five spice powder, so that the five spice flavor of the cashew is rich; the cashew subjected to quick oil frying is crispy and delicious and meets the demand of people on flavor and taste.

Owner:良品铺子股份有限公司

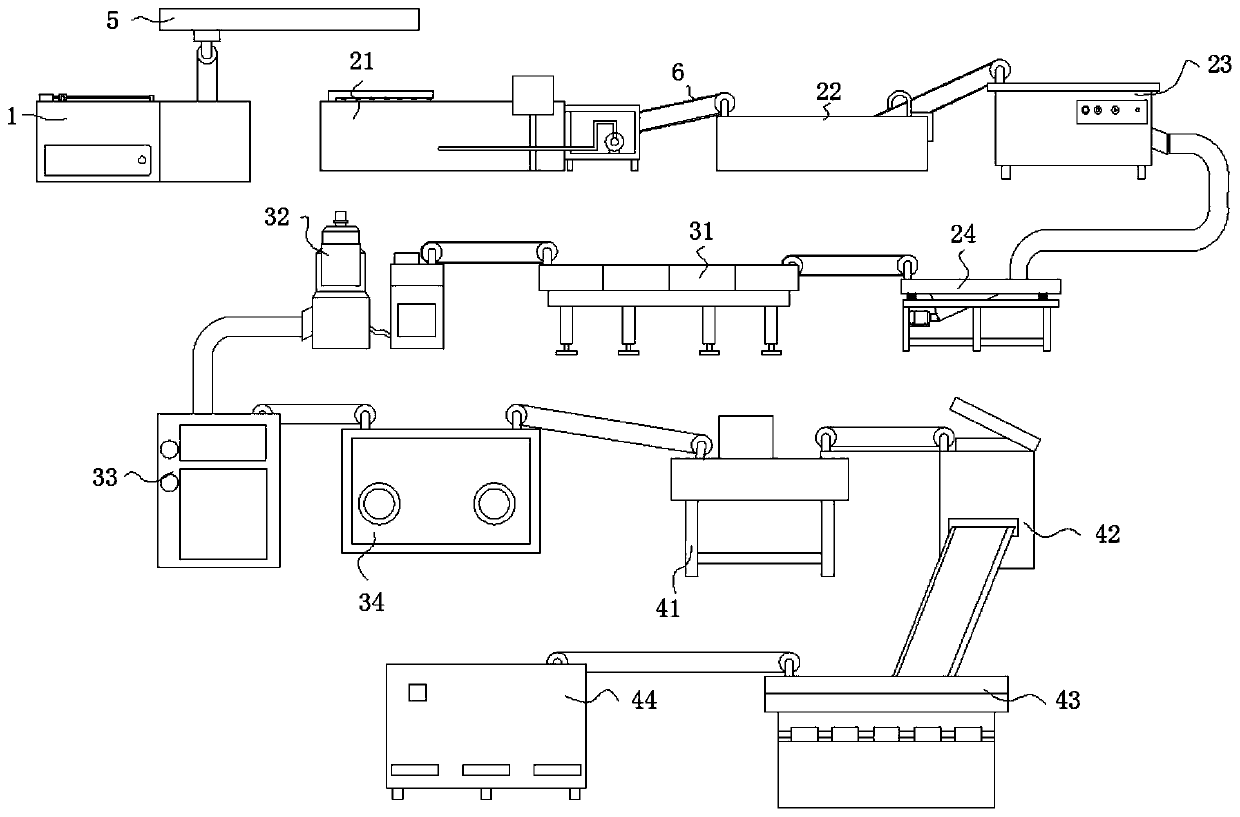

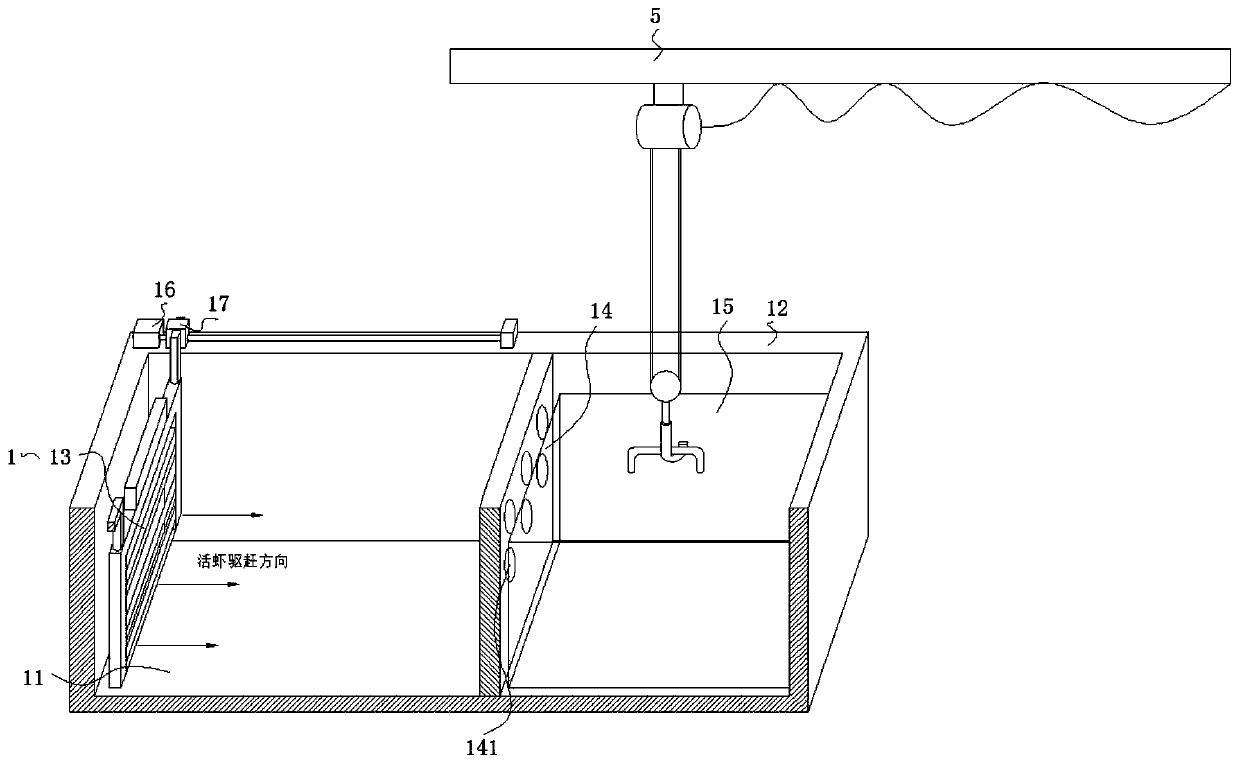

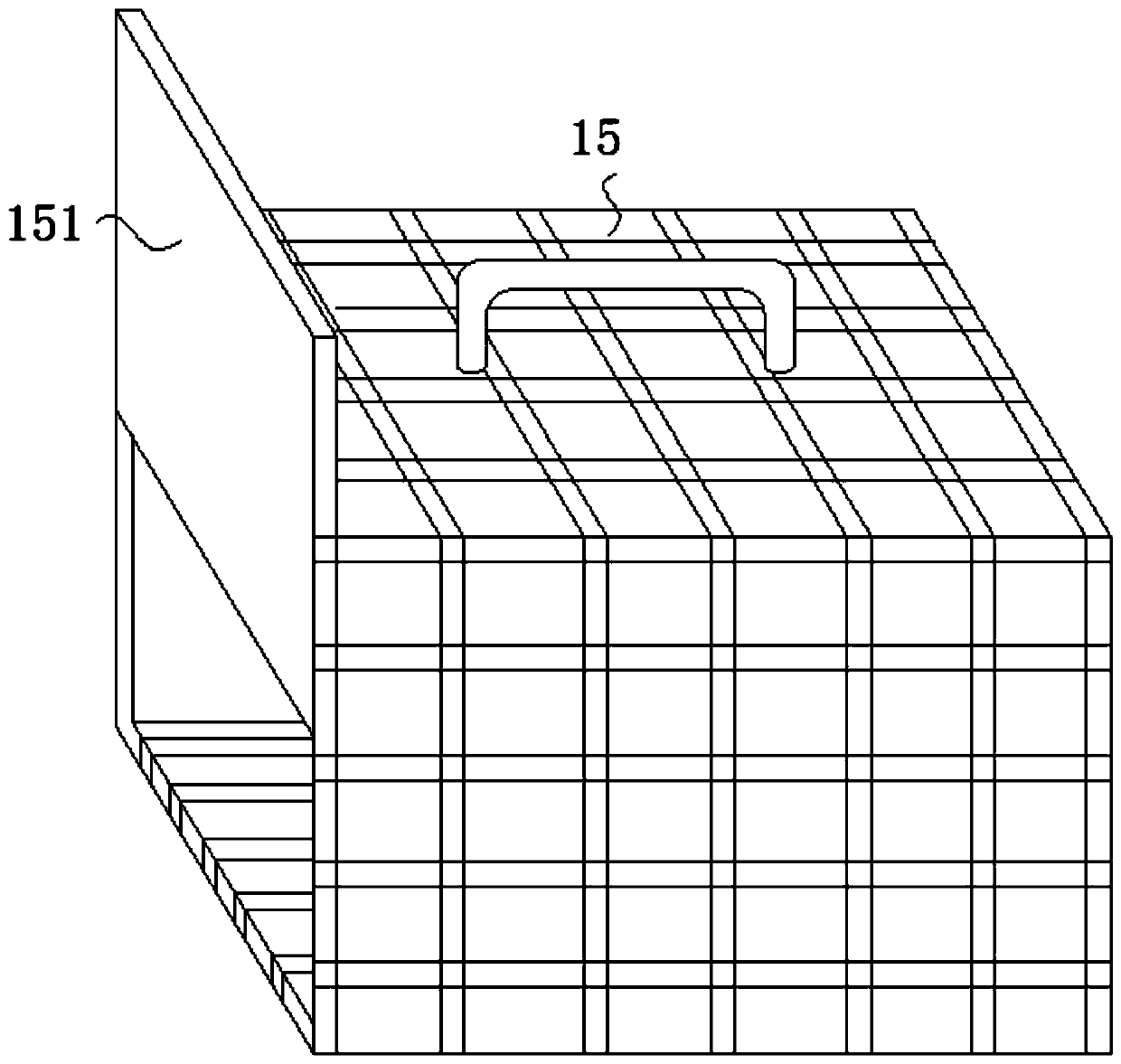

Assembly-line processing device and technology of quick-frozen spicy crayfishes

PendingCN110101038AIncrease elasticityImprove chewinessOil/fat bakingShellfish/bivalves grading/classificationBiochemical engineeringAssembly line

The invention discloses assembly-line processing device and technology of quick-frozen spicy crayfishes. The device comprises an electric pulse dead crayfish separating system, a cleaning system, a cooking system and a packaging and quick-freezing system. The device is characterized in that a lifting machine is arranged at the top of the electric pulse dead crayfish separating system, a cleaning system is arranged at one side of the bottom of the lifting machine, a conveying belt is connected between the cleaning system and the cooking system, and the cooking system is connected with the packaging and quick-freezing system through the conveying belt. The processing technology of the quick-frozen spicy crayfishes comprises the steps of 1, separating, 2, cleaning, 3, cooking and 4, packagingand quick-freezing, wherein in step 1, fresh crayfishes purchased from the market are put in a separating pool, a power supply of an electric pulse crayfish shocking instrument is connected, the pulsed voltage of electrode plates is 150-200 V, and the power of the electrode plates is 80-100 W. The assembly-line processing device and technology have the advantages that the processing efficiency ishigh, and the crayfishes have good meat flavor.

Owner:韩文静

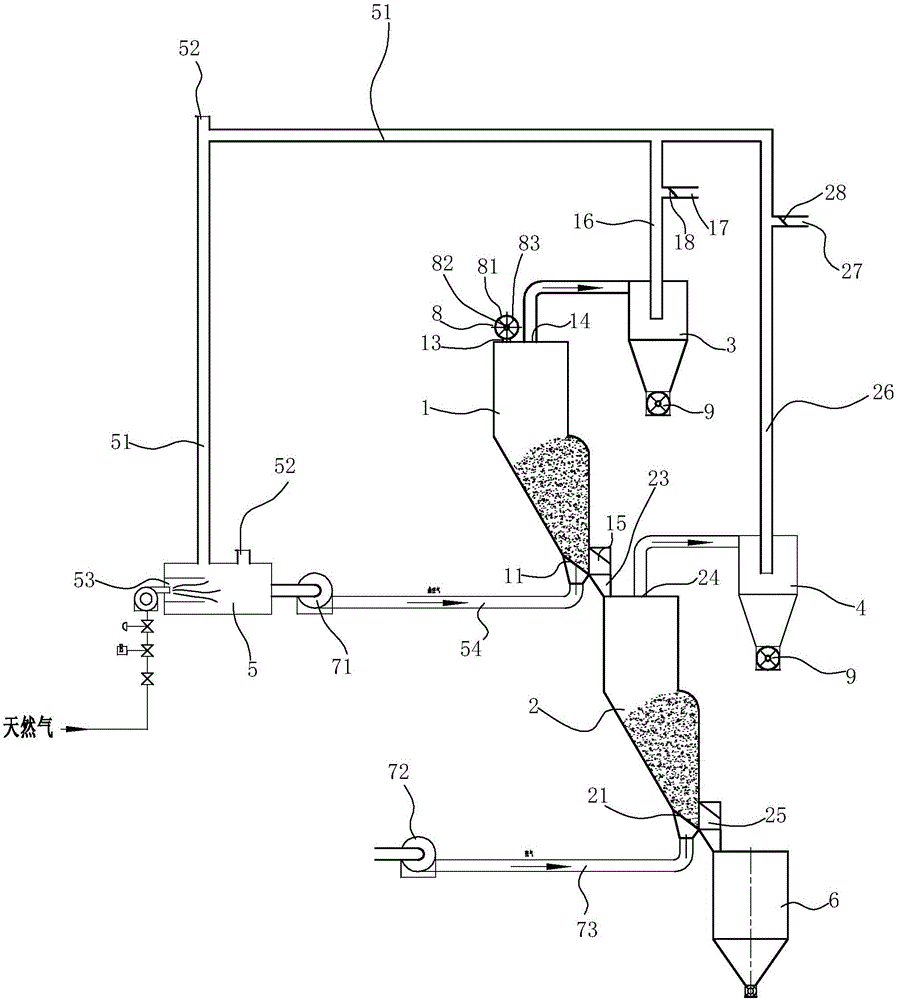

Cereal stir-frying system

The invention relates to a cereal stir-frying system. The cereal stir-frying system is characterized by comprising a roasting chamber with a gas distributor, and a cooling chamber, wherein the roasting chamber communicates with an air heating chamber and a first dust remover, hot wind exhausted from the first dust remover returns to the air heating chamber, a discharge opening of the roasting chamber is connected with a feed opening of the cooling chamber, the cooling chamber communicates with a cold air pipeline and a second dust remover, and hot wind after heat exchange returns to the air heating chamber. According to the cereal stir-frying system disclosed by the invention, cereals are heated under the state of stirring, so that the heat exchange efficiency is high, the stir-frying speed is high, the production efficiency is high, gravels are prevented from being used, raw materials are hygienic, free from foreign matters and environmental-friendly, and the hygiene is guaranteed; besides, the gravels are not used as heating mediums, and subsequent separation equipment is not needed, so that the stir-frying time is shortened; control effects on protein denaturation and starch dextrinization degrees of cereals are good, the raw materials are uniformly heated, the quality is stable, and the problems of scorching the raw materials and the like cannot be caused.

Owner:NINGBO CHANGRONG BREWING EQUIP

Environmentally-friendly high-efficiency electromagnetic melon seed roasting machine

InactiveCN108541975AEfficient dust removalShorten frying timeFood treatmentEngineeringEnvironmentally friendly

The invention discloses an environmentally-friendly high-efficiency electromagnetic melon seed roasting machine. The environmentally-friendly high-efficiency electromagnetic melon seed roasting machine comprises a debris-collecting box, a dust-collecting box, a heating chamber, a feeding hopper, a controller, a stir-frying apparatus, fans and a heating apparatus; the feeding hopper is arranged ata right end of an upper surface of the heating chamber; the stir-frying apparatus is arranged at the middle of the heating chamber; fans are arranged on an inner side of a left side wall of the heating chamber; the dust-collecting box is arranged on a right side of the heating chamber; a first material outlet is arranged on a left side of a lower surface of the heating chamber; the heating chamberis a double-layer structure, and is arranged with a heating apparatus between the inner walls and the outer walls; the heating apparatus is in electric connection with the controller; the debris-collecting box is arranged at a lower end of the heating chamber; a vibration sieve plate is arranged, in an inclined way, at the middle of the debris-collecting box; the vibration sieve plate is in electric connection with the controller; and a second material outlet is arranged on a right side of the debris-collecting box. The environmentally-friendly high-efficiency electromagnetic melon seed roasting machine provided by the invention is capable of effectively removing dust, and high in work efficiency.

Owner:许昌智工机械制造有限公司

Processing method of nostoc commune mutton sauce

The invention relates to a processing method of a nostoc commune mutton sauce. The processing method comprises the following steps of (1) taking fresh mutton, cutting the taken mutton into mutton blocks, and pre-cooking the mutton blocks to obtain pre-cooked mutton; (2) taking scallions and ginger to make deodorization materials; (3) steaming the pre-cooked mutton, and cutting the steamed mutton into diced mutton; (4) deep-frying the diced mutton with soybean oil; (5) taking fresh nostoc commune, and cutting up the taken nostoc commune; (6) taking peanut oil, dry red chili and water, and performing heating for decoction to obtain decocted materials; and (7) heating the decocted materials to 150-160 DEG C, then adding the deep-fried mutton, performing stir-frying, adding a chili sauce, continuing stir-frying, finally adding the cut-up nostoc commune, table salt and chicken essence, performing uniform stirring, performing cooling, performing measurement, and performing packaging so as to obtain the nostoc commune mutton chili. According to the making method of the mutton sauce, the mutton and the nostoc commune are combined, so that the made mutton sauce not only reserves the nutrients of the nostoc commune but also is rich in delicious taste of the mutton; and in the making process, deodorization treatment is not performed on the mutton with wine, but a fresh, fragrant and delicious mutton sauce can still be made.

Owner:白娟娟

Processing method of spicy diced rabbit

The invention relates to a processing method of spicy diced rabbit, which comprises the following steps: (1) taking whole rabbits, cutting them into large pieces, and precooking them to obtain precooked rabbit meat; (2) taking scallions, ginger and rice wine, and making curd Seasoning; (3), precooked rabbit meat, cut into small cubes; (4), fried spices; (5), made spice sauce; (6), stewed rabbit meat; (7), fried rabbit meat; (8) ), making spicy sauce; (9), frying and packaging. In the processing method of the spicy diced rabbit of the present invention, the rabbit meat is first steamed and then fried, which can not only reduce the frying time of the rabbit meat, but also improve the final taste of the rabbit meat, and, after frying with the spicy sauce, the color is increased, The color, aroma and taste are complete, the nutritional value is relatively high, and the taste is relatively mellow and strong.

Owner:白娟娟

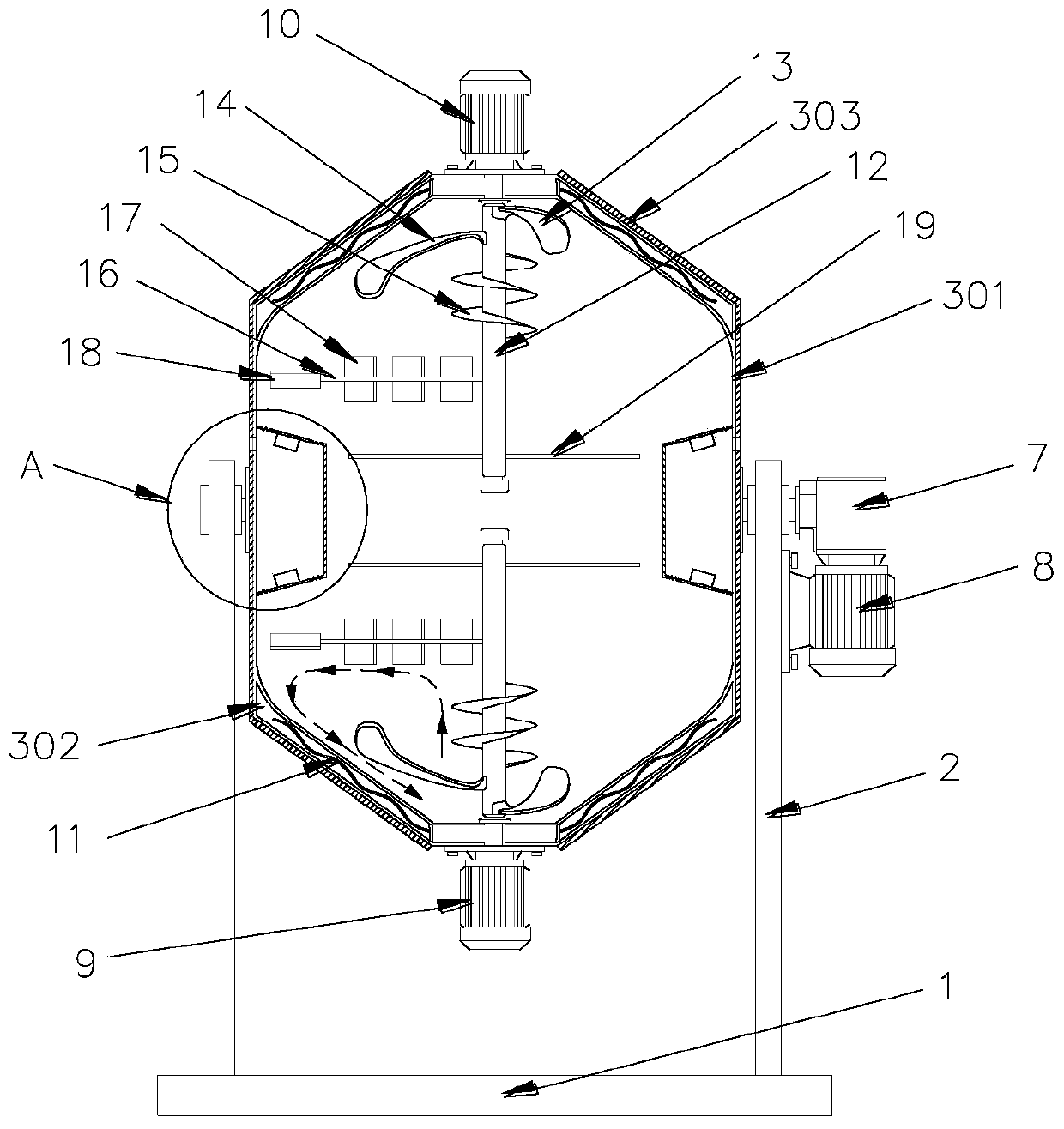

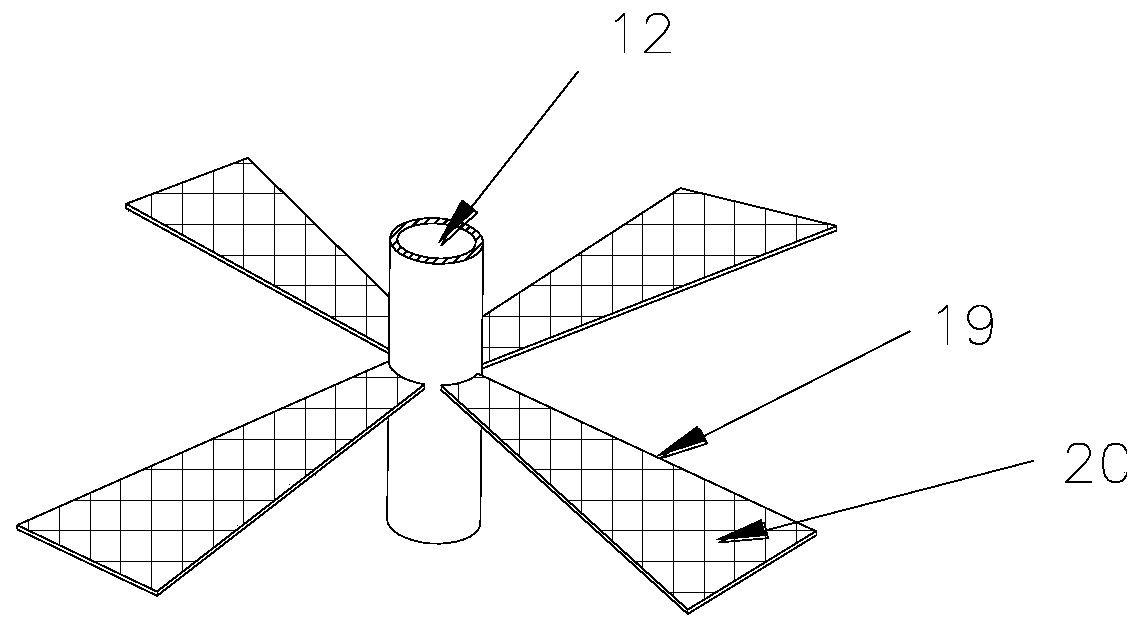

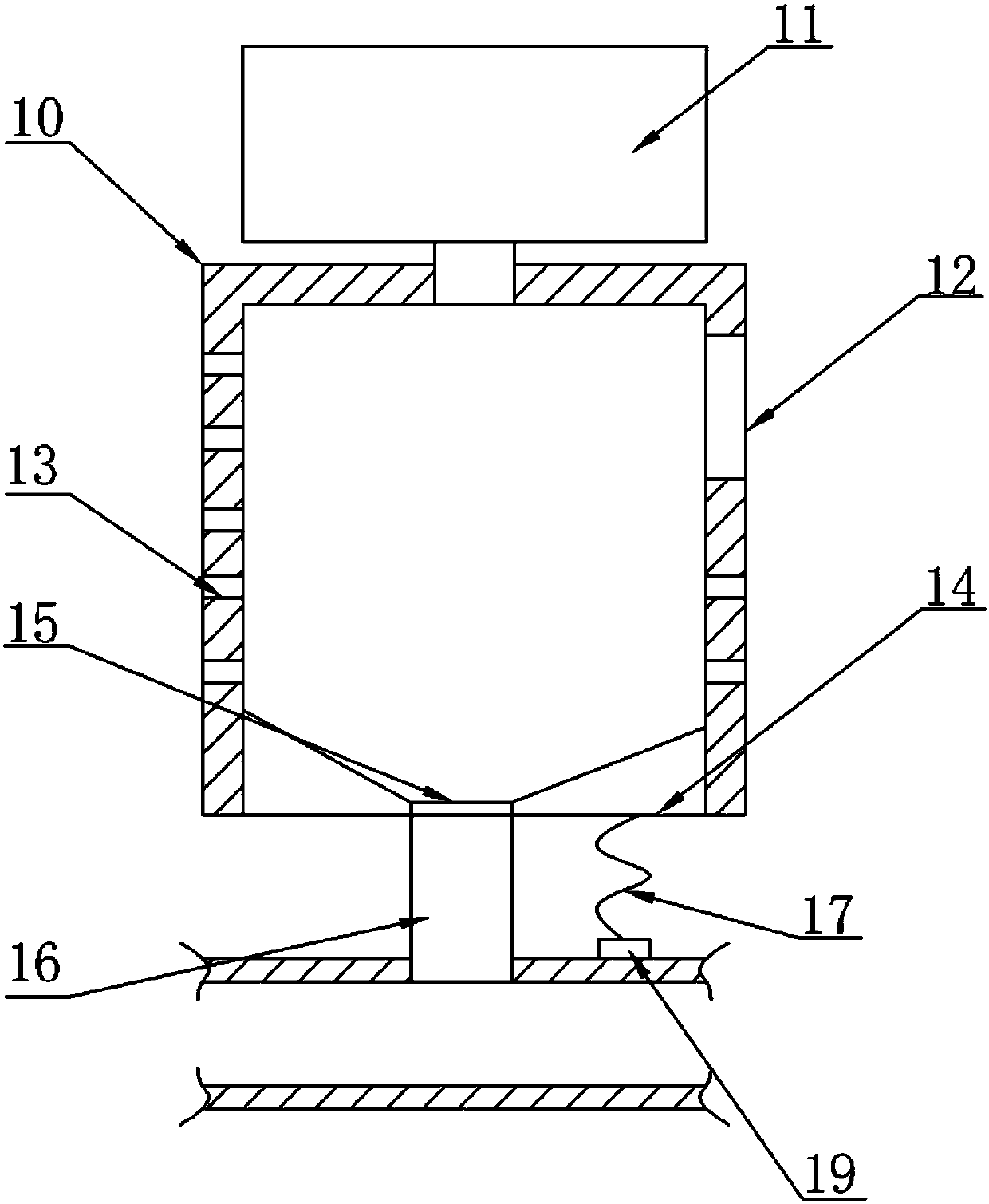

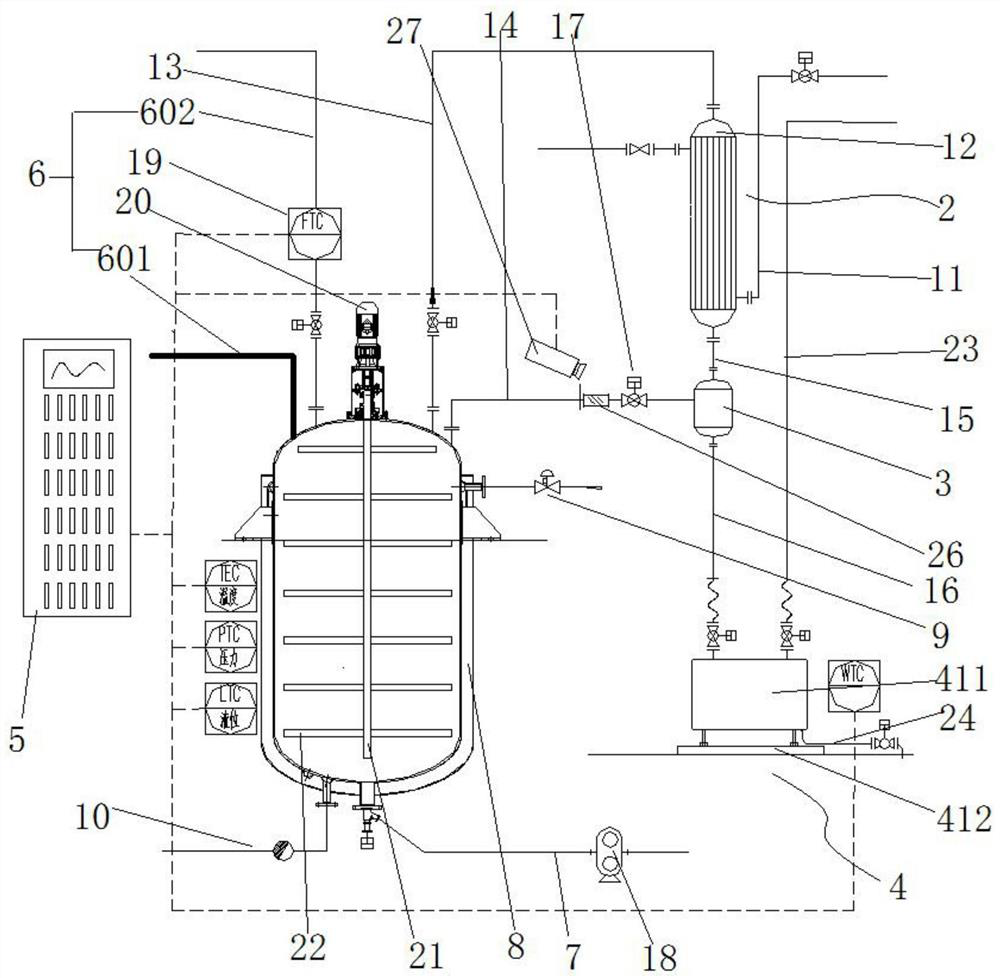

Hotpot condiment stir-frying method and equipment thereof

The invention discloses a hotpot condiment stir-frying method and equipment thereof. The hotpot condiment stir-frying equipment comprises a reaction kettle, a heat exchanger, an oil-water separation tank, a weighing water tank and an electric control box, a stirring mechanism and a material inlet are arranged at the top end of the reaction kettle, and a material outlet is formed in the bottom end of the reaction kettle; The reaction kettle is externally sleeved by a heating cover, and the heating cover is provided with a steam inlet and a condensate outlet. The heat exchanger comprises a cooling water pipe and a heat exchange cylinder, the upper end of the reaction kettle is communicated with the upper end of the heat exchange cylinder through a first pipeline, and the upper end of the reaction kettle is communicated with the upper end of the oil-water separation tank through a second pipeline; the lower end of the heat exchange cylinder communicates with the upper end of the oil-water separation tank through a third pipeline, the lower end of the oil-water separation tank communicates with the weighing water tank through a fourth pipeline, and the material outlet communicates with a discharging pump. According to the invention, the stir-frying production is efficient, the operation is simple, the temperature rise speed can be adjusted, and rapid cooling and rapid water discharge can be realized so that the stir-frying effect is the same as that of a traditional stir-frying pan.

Owner:聚豪食品(重庆)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com