Cereal stir-frying system

A grain frying system and roasting technology, which are applied in the direction of storing seeds by drying, etc., can solve the problems of increasing the separation difficulty of the separation process of quartz sand and wheat, the frying efficiency needs to be further improved, and the cooling speed is slow, so as to shorten the frying speed. time, improve the effect of energy saving and consumption reduction, and the effect of fast frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

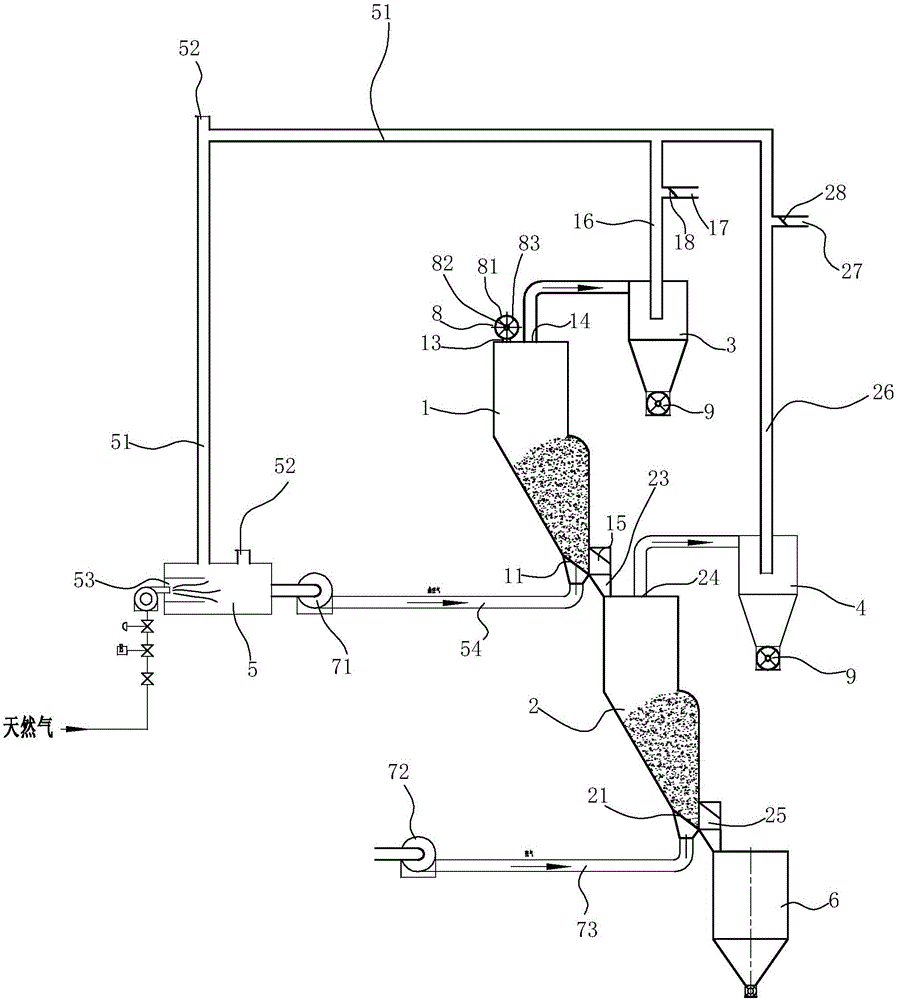

[0022] Such as figure 1 As shown, the grain frying system includes:

[0023] The roasting chamber 1 is used for heating and cooking the wheat; the lower part of the roasting chamber 1 is roughly in a right-angled triangle structure, and the upper part of the roasting chamber is a cube structure, and the upper part of the roasting chamber is connected to the right-angled side of the lower part of the roasting chamber . The lower part of the roasting chamber 1 is provided with a first gas distributor 11 that prevents the wheat to be roasted from passing through at the position close to the sharp angle slope. An air flow chamber is connected below the first gas distributor 11. The upper end surface of the air flow chamber is connected to the first gas distribution chamber. The device 11 is docked, and the area of the lower end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com