Assembly-line processing device and technology of quick-frozen spicy crayfishes

A technology of spicy lobster and processing equipment, which is applied in shrimp/lobster processing, crustacean processing, meat/fish preservation, etc., can solve the problems of deterioration of flavor, influence on the taste of shrimp, weakening of unique aroma, etc., to improve elasticity and chewiness The process of immersion and taste is simple, and the effect of enhancing the hydrophobic interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

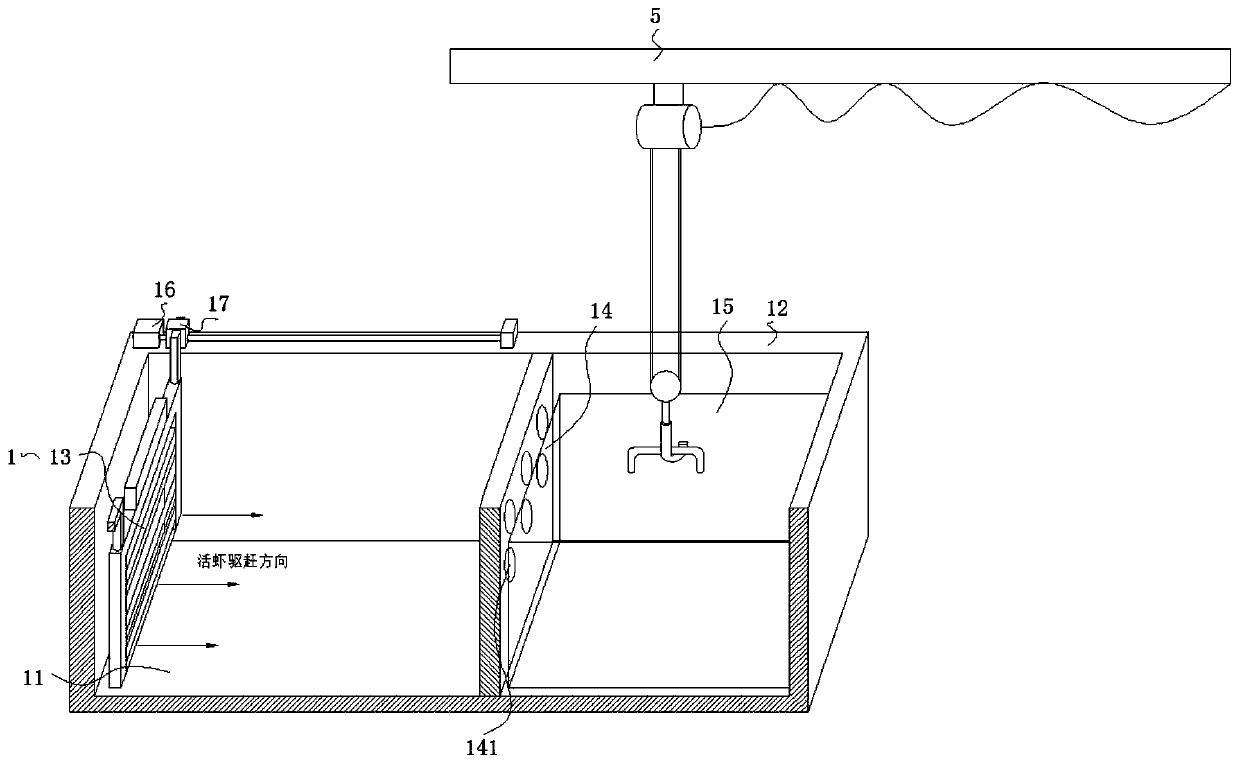

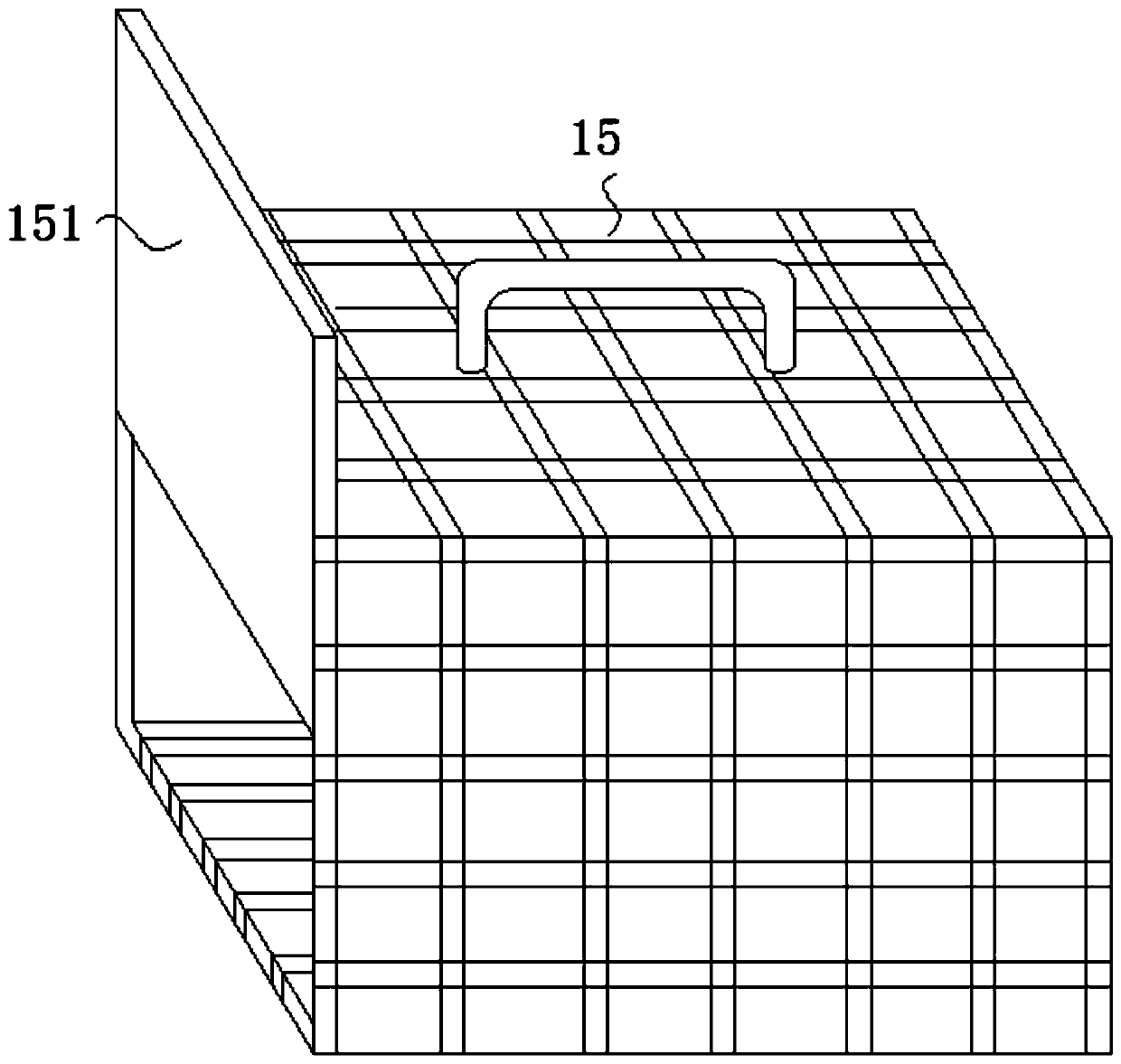

[0064] Step 1, put the lobster purchased on the market into the separation tank 11, connect the power supply of the electric pulse shocking shrimp instrument 13, the pulse voltage is 165V, and the power is 90W;

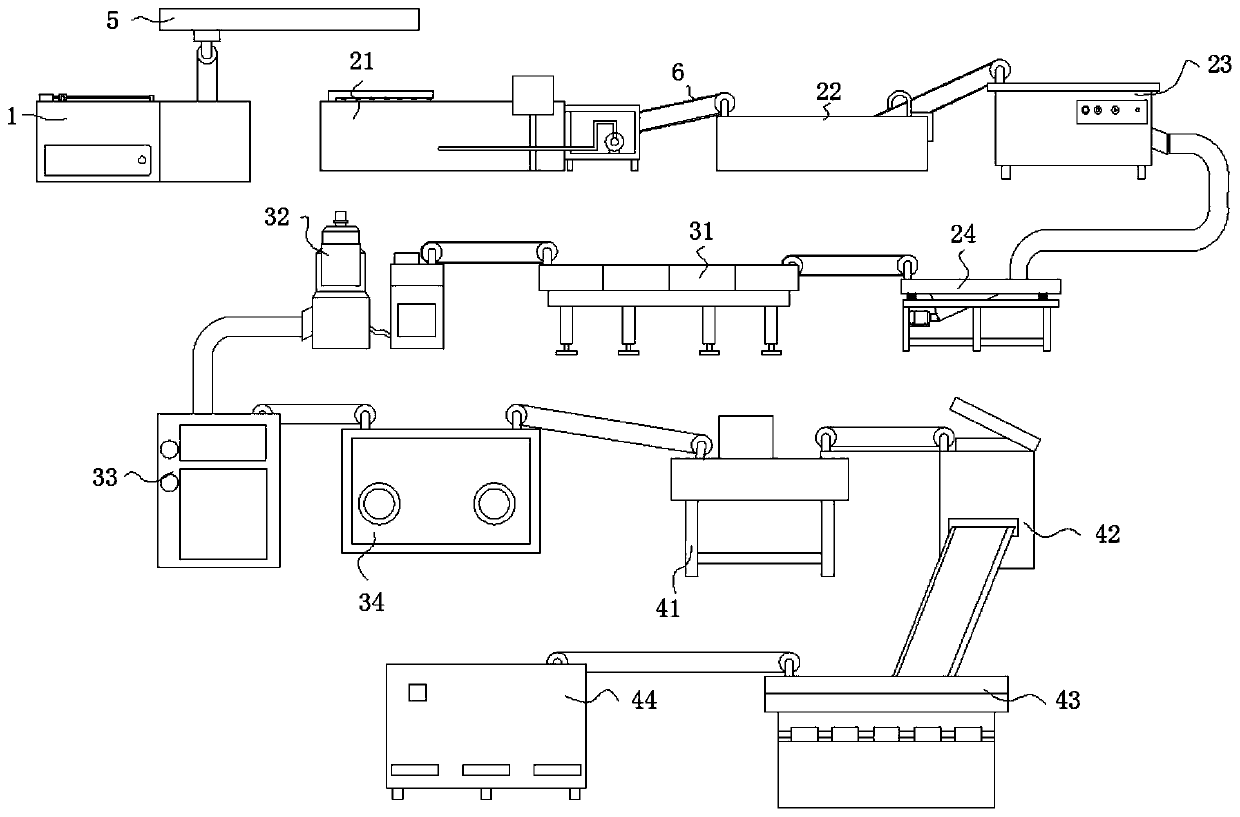

[0065] Step 2, 1) Put the lobster into the aquatic product washing machine 21, and use 0.2MPa high-pressure water flow to wash off the silt and grass blades on the shrimp body;

[0066] 2) Put the lobster into the cleaning solution pool 22 prepared with the cleaning solution. The cleaning solution is made by mixing 0.3% baking soda, 3.5% white vinegar and 12% table salt with water, and the oxygen is increased under the action of the aeration pump Soak for 40 minutes to clean the gills and intestinal dirt of the lobster;

[0067] 3) The lobster is sent into the ultrasonic lobster cleaning machine 23 through the conveyor belt, the ultrasonic frequency is 25kHz, the silt content of the water is detected by an infrared silt sensor, and the lobster is repeatedly cleaned un...

Embodiment 2

[0087] Step 1, put the lobster purchased on the market into the separation tank 11, connect the power supply of the electric pulse shocking shrimp instrument 13, the pulse voltage is 150V, and the power is 100W;

[0088] Step 2, 1) Put the lobster into the aquatic product washing machine 21, and use 0.2MPa high-pressure water flow to wash off the silt and grass blades on the shrimp body;

[0089] 2) Put the lobster into the cleaning solution pool 22 prepared with the cleaning solution. The cleaning solution is made by mixing 0.3% baking soda, 3.5% white vinegar and 12% table salt with water, and the oxygen is increased under the action of the aeration pump Soak for 38 minutes to clean the gills and intestinal dirt of the lobster;

[0090] 3) The lobster is sent into the ultrasonic lobster cleaning machine 23 through the conveyor belt, the ultrasonic frequency is 25kHz, the silt content of the water is detected by an infrared silt sensor, and the lobster is repeatedly cleaned u...

Embodiment 3

[0108] Step 1, put the lobster purchased on the market into the separation tank 11, connect the power supply of the electric pulse shocking shrimp instrument 13, the pulse voltage is 150V, and the power is 100W;

[0109] Step 2, 1) Put the lobster into the aquatic product washing machine 21, and use 0.2MPa high-pressure water flow to wash off the silt and grass blades on the shrimp body;

[0110] 2) Put the lobster into the cleaning solution pool 22 prepared with the cleaning solution. The cleaning solution is made by mixing 0.3% baking soda, 3.5% white vinegar and 12% table salt with water, and the oxygen is increased under the action of the aeration pump Soak for 30 minutes to clean the gills and intestinal dirt of the lobster;

[0111] 3) The lobster is sent into the ultrasonic lobster cleaning machine 23 through the conveyor belt, the ultrasonic frequency is 25kHz, the silt content of the water is detected by an infrared silt sensor, and the lobster is repeatedly cleaned u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com