Processing method of residue-free beef tallow hotpot condiment

A processing method and hot pot bottom material technology, which is applied in the field of non-slag butter hot pot bottom material processing, can solve the problems of increased difficulty in temperature and time control, large influence of human factors, and unstable product quality, so as to reduce foreign matter entering the hot pot bottom The risk of materials, the convenience of automatic control, and the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

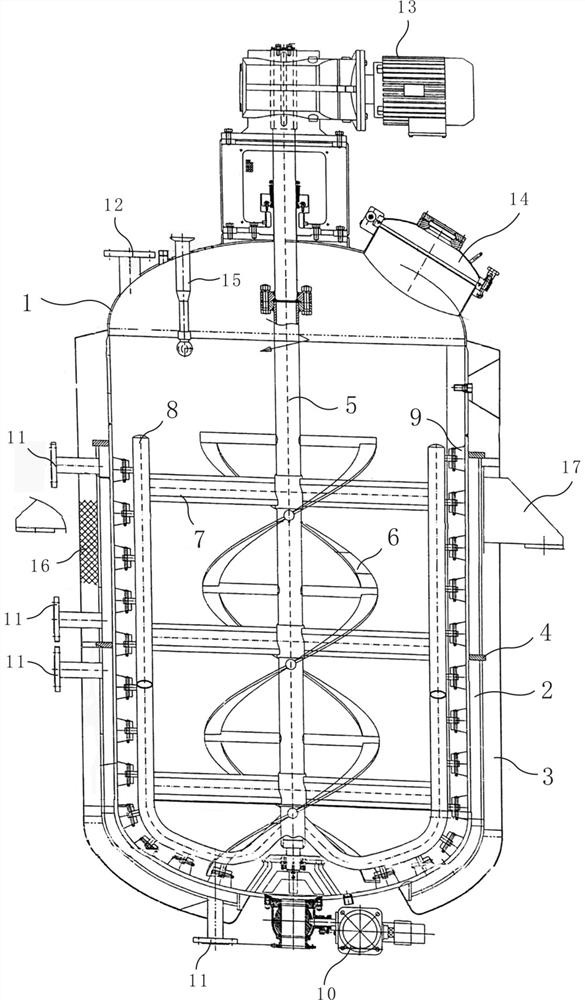

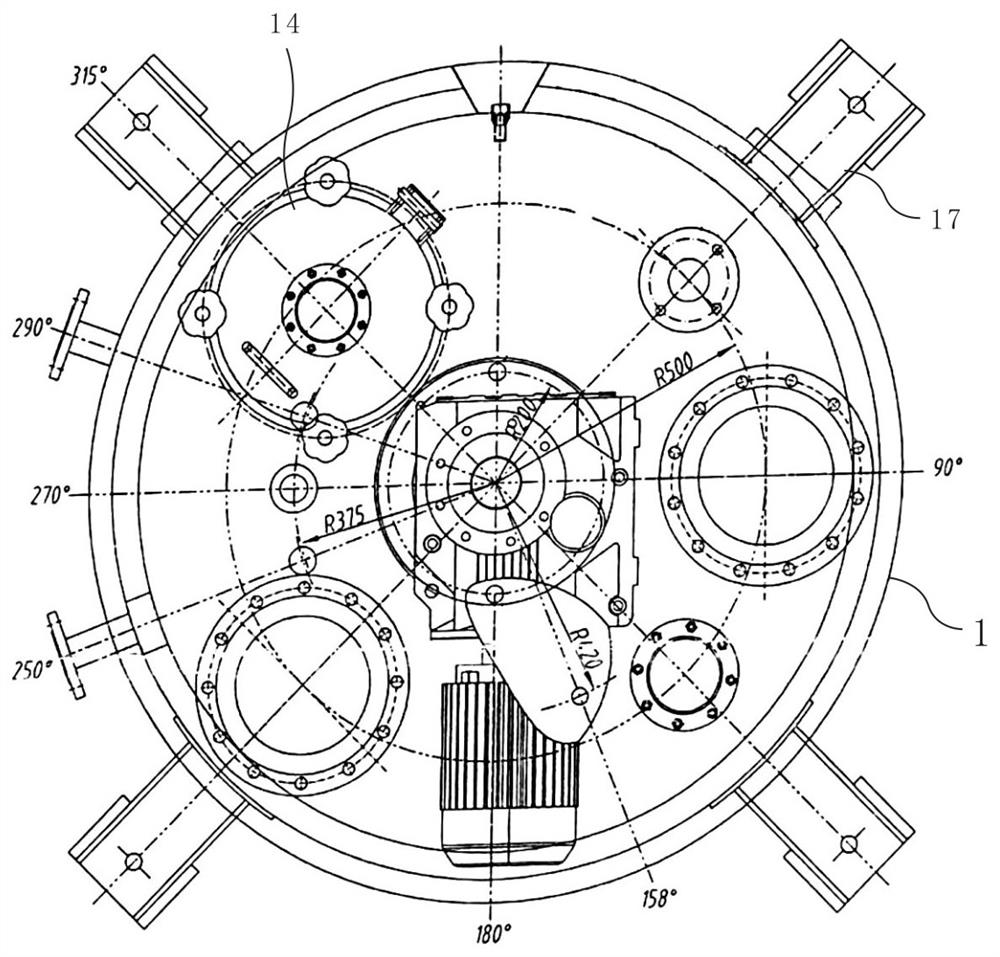

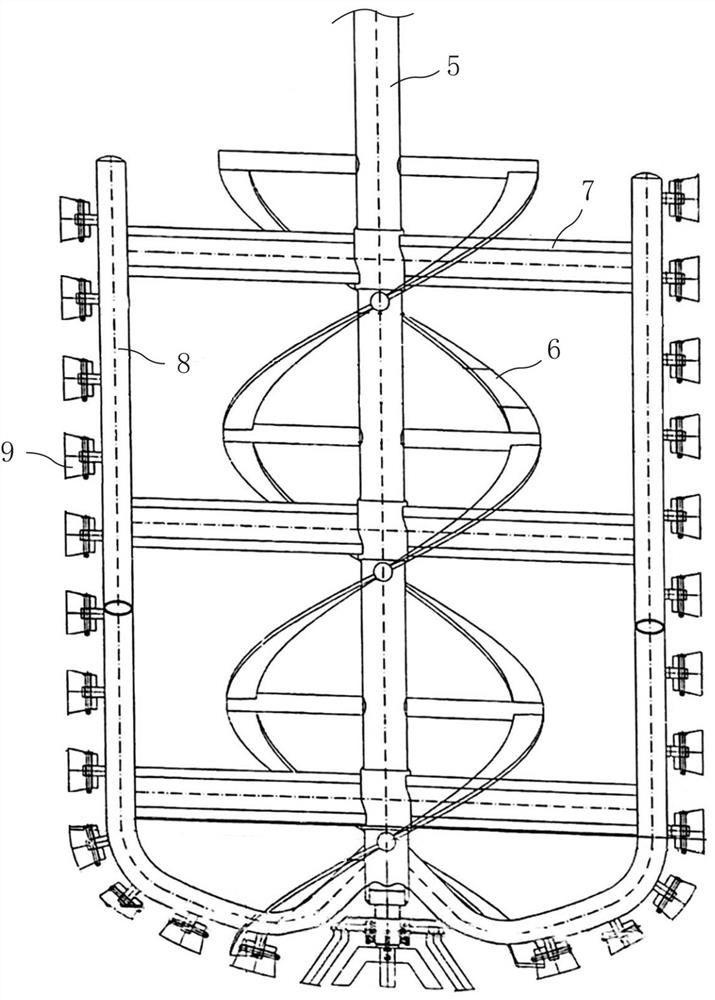

[0041] This embodiment is used to illustrate the concrete structure of reactor: as figure 1 Shown, a kind of frying equipment for frying chafing dish bottom material, comprises

[0042] Kettle body 1, the kettle body is closed, with a discharge port with a valve at the bottom, a feeding port at the top, and a frying area formed inside the kettle body 1, which extends upward from the bottom of the kettle body And smaller than the internal space of the kettle body;

[0043] The stirring mechanism is installed vertically in the kettle body to evenly stir the materials; and

[0044] The stirring power unit is installed outside the kettle body and connected with the stirring mechanism;

[0045] The outer wall of the kettle body 1 is provided with a heating interlayer 2 for heating the frying area, and an insulating layer 3 is arranged on the outer wall of the heating interlayer, and an insulating material 16 is filled in the insulating layer.

[0046] The stirring power unit inc...

Embodiment 2

[0060] This embodiment is used to illustrate the overall processing method of non-slag property butter chafing dish bottom material:

[0061] A method for processing non-slag-free butter hot pot bottom material, comprising:

[0062] ①The raw materials are pretreated. Among them, the pretreatment method of peppers is as follows: the new generation and Gypsophila go through stone removal, dust removal, color sorting, X-ray selection, and after cutting and removing seeds, they are processed with a pepper cooking machine. The parameters are set as follows: The valve opening temperature is 86°C, the valve closing temperature is 87°C, the limited lifting frequency is 20HZ, the conveying frequency of boiled pepper is 40HZ, the reserve conveying frequency is 50HZ, and a sieve plate of 8-15mm is selected. The actual temperature measured on the dial of the cooking pepper line is 80-85°C.

[0063] Table 1 shows the pretreatment requirements for ginger, garlic, onion, and coriander.

[...

Embodiment 3

[0079] The raw material formula of this embodiment is as shown in table 2.

[0080] Table 2

[0081] .

[0082] The preparation process refers to Example 2, the difference is that: the steam pressure is 0.8Mpa, the frying temperature of watercress and tempeh is 109°C for 2 minutes, the frying temperature of pepper is 107°C for 65 minutes, and the frying temperature of Zanthoxylum bungeanum is 107°C for 65 minutes. 116 DEG C, the time is 3min, the frying temperature of liquor and small ingredients is 115 DEG C, the time is 2min, all the other processes are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com