Luncheon meat flavor paste and preparation method thereof

A technology for luncheon meat and flavor paste, which is applied in the fields of food science, sugar-sweetened food ingredients, applications, etc., can solve the problems of undiscovered patent publications and the like, and achieve the effects of prominent characteristic flavor, soft taste, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

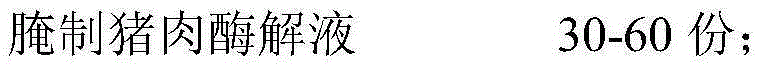

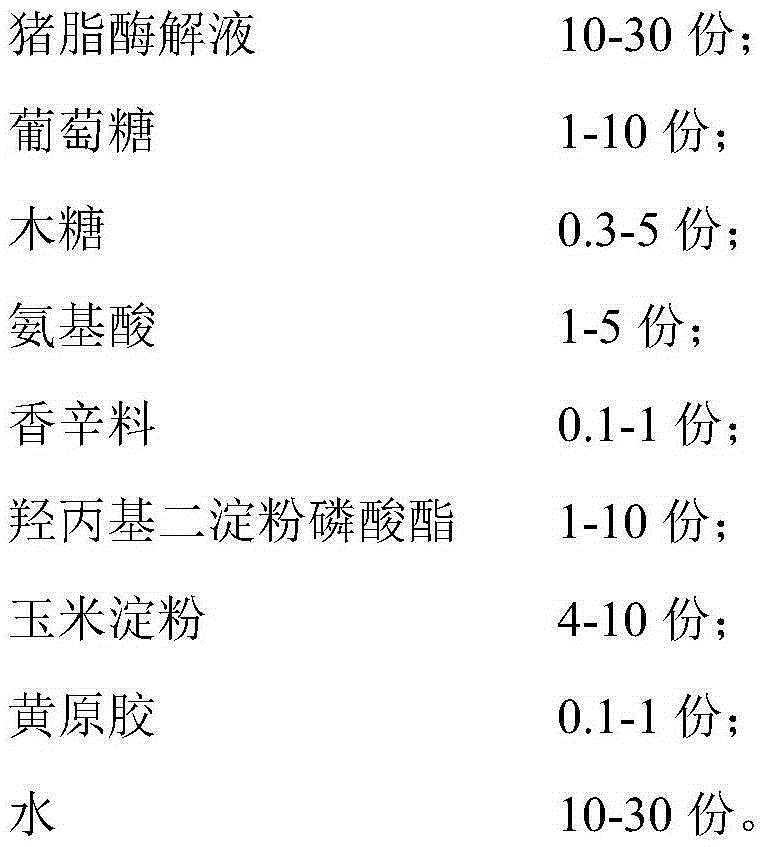

[0030] A kind of lunch meat flavor paste, its composition and parts by weight are as follows:

[0031] 50 parts of cured pork enzymatic solution, 20 parts of pig fat enzymatic solution, 2 parts of glucose, 0.5 part of xylose, 0.4 part of arginine, 0.6 part of alanine, 0.5 part of cysteine, 0.5 part of spices, hydroxypropyl 2 parts of base distarch phosphate, 5 parts of corn starch, 0.4 part of xanthan gum, and 20 parts of water.

[0032] The preparation method of the above-mentioned luncheon meat flavor paste, the steps are as follows:

[0033] (1) In parts by weight, weigh 60 parts of cured pork, add 40 parts of drinking water, put it into a reaction tank, heat up to 50°C-60°C while stirring, add 0.2 parts of trypsin, 0.2 parts of papain 0.2 part of neutral protease, 0.4 part of flavor protease, heat preservation and stirring for 2.5 hours, then raise the temperature to 95°C, keep it for 20 minutes, then cool to room temperature for later use, and obtain the marinated pork e...

Embodiment 2

[0038] A kind of lunch meat flavor paste, its composition and parts by weight are as follows:

[0039] 60 parts of cured pork enzymatic solution, 15 parts of pig fat enzymatic solution, 1 part of glucose, 0.3 parts of xylose, 0.3 parts of arginine, 0.5 parts of alanine, 0.6 parts of cysteine, 0.6 parts of spices, hydroxypropyl 3 parts of base distarch phosphate, 4 parts of corn starch, 0.3 part of xanthan gum, and 15 parts of water.

[0040] The preparation method of the above-mentioned luncheon meat flavor paste, the steps are as follows:

[0041] (1) In parts by weight, weigh 55 parts of cured pork, add 45 parts of drinking water, put it into a reaction tank, heat up to 50°C-60°C while stirring, add 0.15 parts of trypsin, 0.15 parts of papain 0.15 parts of neutral protease, 0.3 parts of flavor protease, heat preservation and stirring for 3 hours, then raise the temperature to 95°C, keep it for 20 minutes, then cool to room temperature for later use, and obtain the marinated...

Embodiment 3

[0046] A kind of lunch meat flavor paste, its composition and parts by weight are as follows:

[0047] 45 parts of cured pork enzymatic solution, 25 parts of pig fat enzymatic solution, 3 parts of glucose, 0.75 parts of xylose, 0.3 parts of arginine, 0.7 parts of alanine, 1 part of cysteine, 0.3 parts of spices, hydroxyl 1 part of propyl distarch phosphate, 6 parts of corn starch, 0.2 part of xanthan gum, 17 parts of water.

[0048] The preparation method of the above-mentioned luncheon meat flavor paste, the steps are as follows:

[0049] (1) In parts by weight, weigh 70 parts of cured pork, add 30 parts of drinking water, put it into a reaction tank, heat up to 50°C-60°C while stirring, add 0.1 part of trypsin, 0.1 part of papain 0.1 part of neutral protease, 0.2 part of flavor protease, insulated and stirred for 4 hours, then heated to 95°C, kept for 20 minutes, then cooled to room temperature for later use, to obtain pickled pork enzymatic hydrolysis solution.

[0050] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com