Preparation method of marinated dried bean curd

A production method and a technology for dried bean curd, applied in the field of food processing, can solve the problems of difficulty in forming flavor raw materials, inability to satisfy, single variety and flavor, etc., and achieve the effects of unique taste and flavor, easy molding, and novel shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

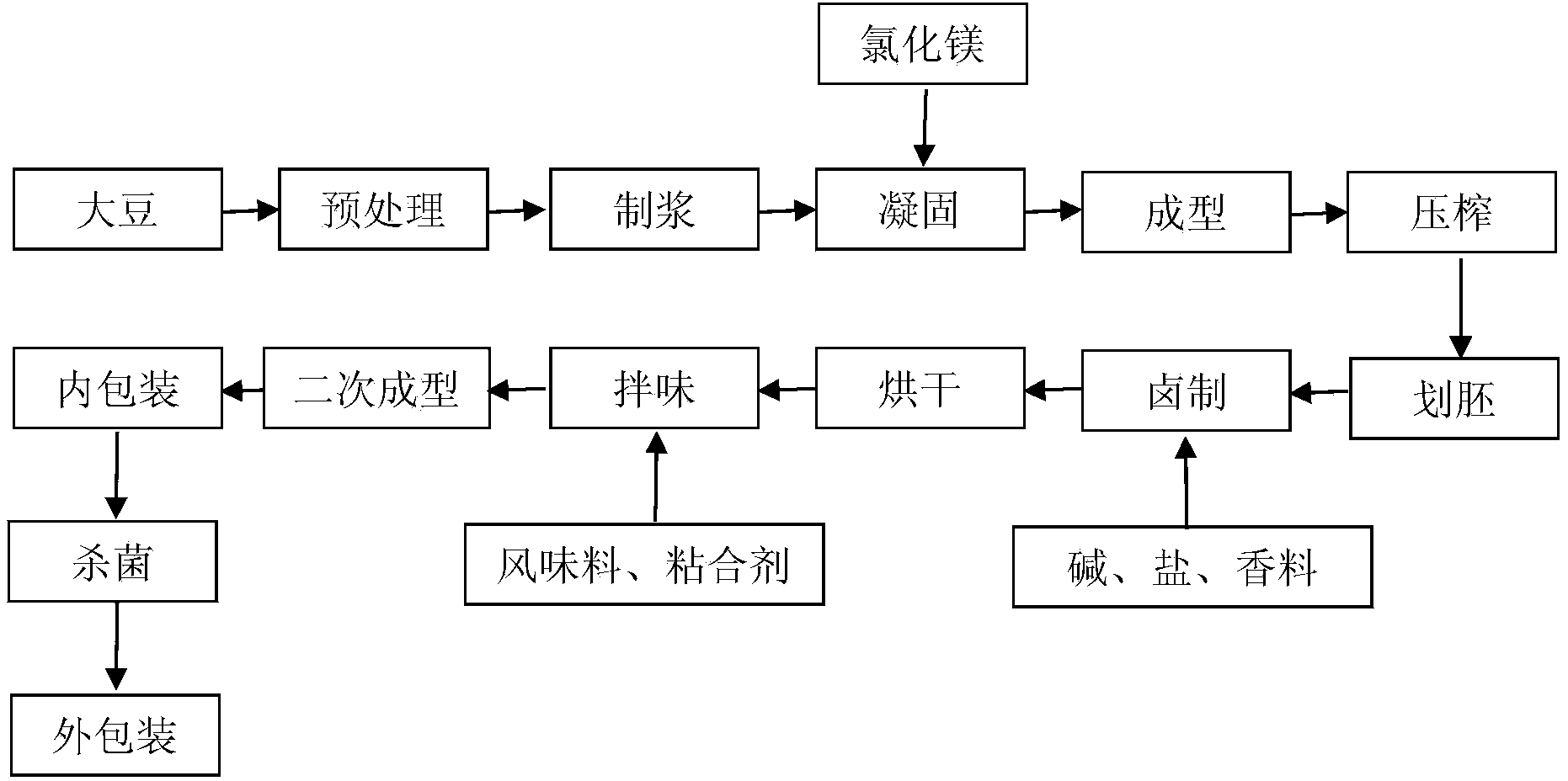

Image

Examples

Embodiment 1

[0027] 1. Soybean pretreatment: remove impurities mixed in harvesting, storage and transportation, such as grass clippings, soil, sand, metal debris, etc., to ensure product hygiene and quality safety.

[0028] 2. Soaking: The ratio of soybeans to tap water is 1:4, the soaking water temperature is 15°C, and the soaking time is 12 hours.

[0029] 3. Refining: When refining, use soft water with a pH value of 7 and a temperature of 60°C, and the amount of water added is 4 times the quality of the soaked soybeans.

[0030] 4. Cook the milk: the temperature of the milk is controlled above 95°C for 8 minutes, and water twice the mass of the soybeans is added to adjust the concentration of the soybean milk to 8.5 degrees.

[0031] 5. Filtration: Immediately filter with an 80-mesh filter.

[0032] 6. Slurry: Dilute the brine block with water to 10 Baume degrees as a coagulant. Put the coagulant into the soymilk while stirring, and stop adding the coagulant when 70% of the watercress...

Embodiment 2

[0042] 1. Soybean pretreatment: remove impurities mixed in harvesting, storage and transportation, such as grass clippings, soil, sand, metal debris, etc., to ensure product hygiene and quality safety.

[0043] 2. Soaking: The ratio of soybeans to tap water is 1:2, the soaking water temperature is 20°C, and the soaking time is 8 hours.

[0044] 3. Refining: When refining, use soft water with a pH value of 7 and a temperature of 70°C, and the amount of water added is 6 times the quality of the soaked soybeans.

[0045] 4. Cooking: The temperature of the cooking should be controlled above 95°C for 10 minutes. Add water 3 times the mass of soybeans to adjust the concentration of soybean milk to 8 degrees.

[0046] 5. Filtration: Immediately filter with a 100-mesh filter.

[0047] 6. Slurry: Dilute the brine block with water to 13 Baume degrees as a coagulant. Put the coagulant into the soy milk while stirring, and stop adding the coagulant when 80% of the bean-shaped tofu flowe...

Embodiment 3

[0057] 1. Soybean pretreatment: remove impurities mixed in harvesting, storage and transportation, such as grass clippings, soil, sand, metal debris, etc., to ensure product hygiene and quality safety.

[0058] 2. Soaking: The ratio of soybeans to tap water is 1:2, the soaking water temperature is 15°C, and the soaking time is 8 hours.

[0059] 3. Refining: When refining, use soft water with a pH value of 7 and a temperature of 50°C, and the amount of water added is 5 times the quality of the soaked soybeans.

[0060] 4. Cooking: The temperature of the cooking should be controlled above 95°C for 10 minutes. Add water 3 times the mass of soybeans to adjust the concentration of soybean milk to 8 degrees.

[0061] 5. Filtration: Immediately filter with a 90-mesh filter.

[0062] 6. Slurry: Dilute the brine block with water to 13 Baume degrees as a coagulant. Put the coagulant into the soybean milk while stirring, and stop adding the coagulant when 90% of the watercress-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com