Soy sauce production method capable of ensuring high protein conversion rate and utilization rate

A production method and technology of conversion rate, applied in application, food preparation, food science, etc., can solve the problems of high energy consumption cost, low degree of automation, low protein conversion rate and utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

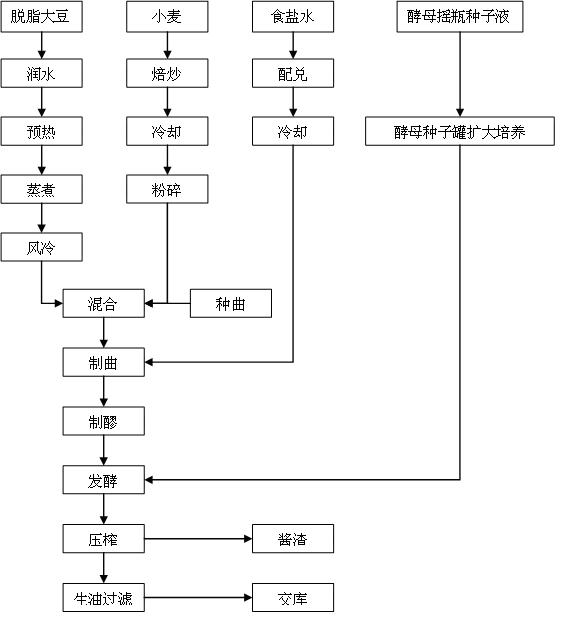

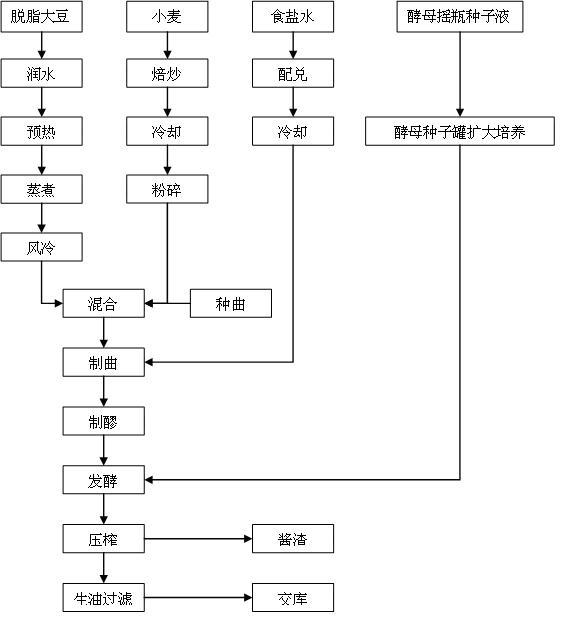

[0030] A kind of soy sauce with high protein conversion rate and utilization rate, the soy sauce is obtained by the following production method:

[0031] (1) Cooking of fatted soybeans: Put 500kg of defatted soybeans into the sprinkler auger through the bucket elevator, and sprinkle hot water (temperature 80-90°C) of 130% of the weight of the defatted soybeans at the same time, and then preheat through the preheating auger, and then enter FM type continuous cooking tank, the temperature in the cooking tank is 130°C, the pressure is 0.18MPa, cook for 5min, and then cool down to 28-33°C through an air cooler.

[0032] (2) Wheat roasting: Turn on the wheat roasting machine, and after half an hour of preheating, the metering auger starts, and the wheat falls into the wheat roasting machine to start roasting. The outlet temperature is required to be 170-190 °C. After frying, the wheat is sent to the cooling machine by the bucket elevator to cool down to below 50°C, and then sent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com