Cereal sausages and production method thereof

A production method and grain technology, applied in food preparation, food science, application, etc., can solve the problems of reducing the nutritional value of corn, reducing the nutritional value of corn or other grains, and low nutrient content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

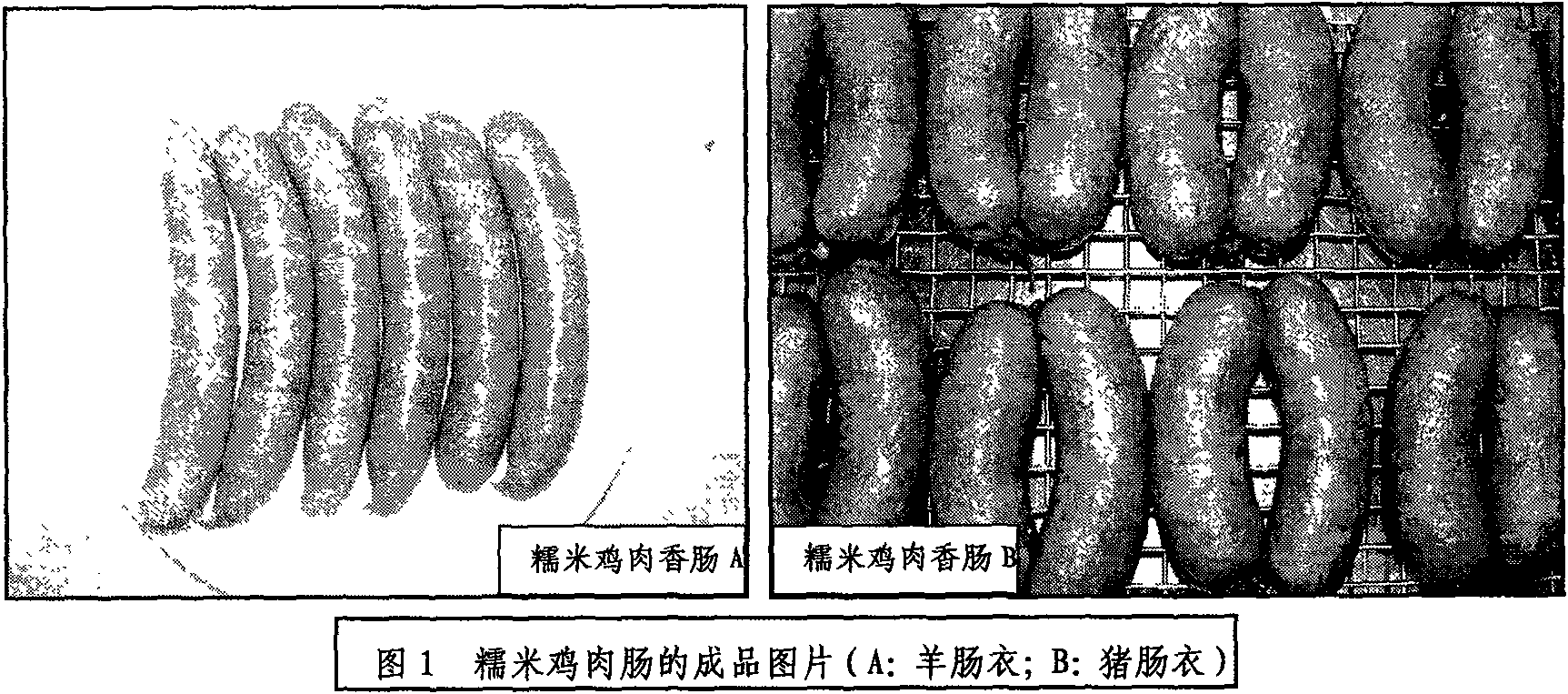

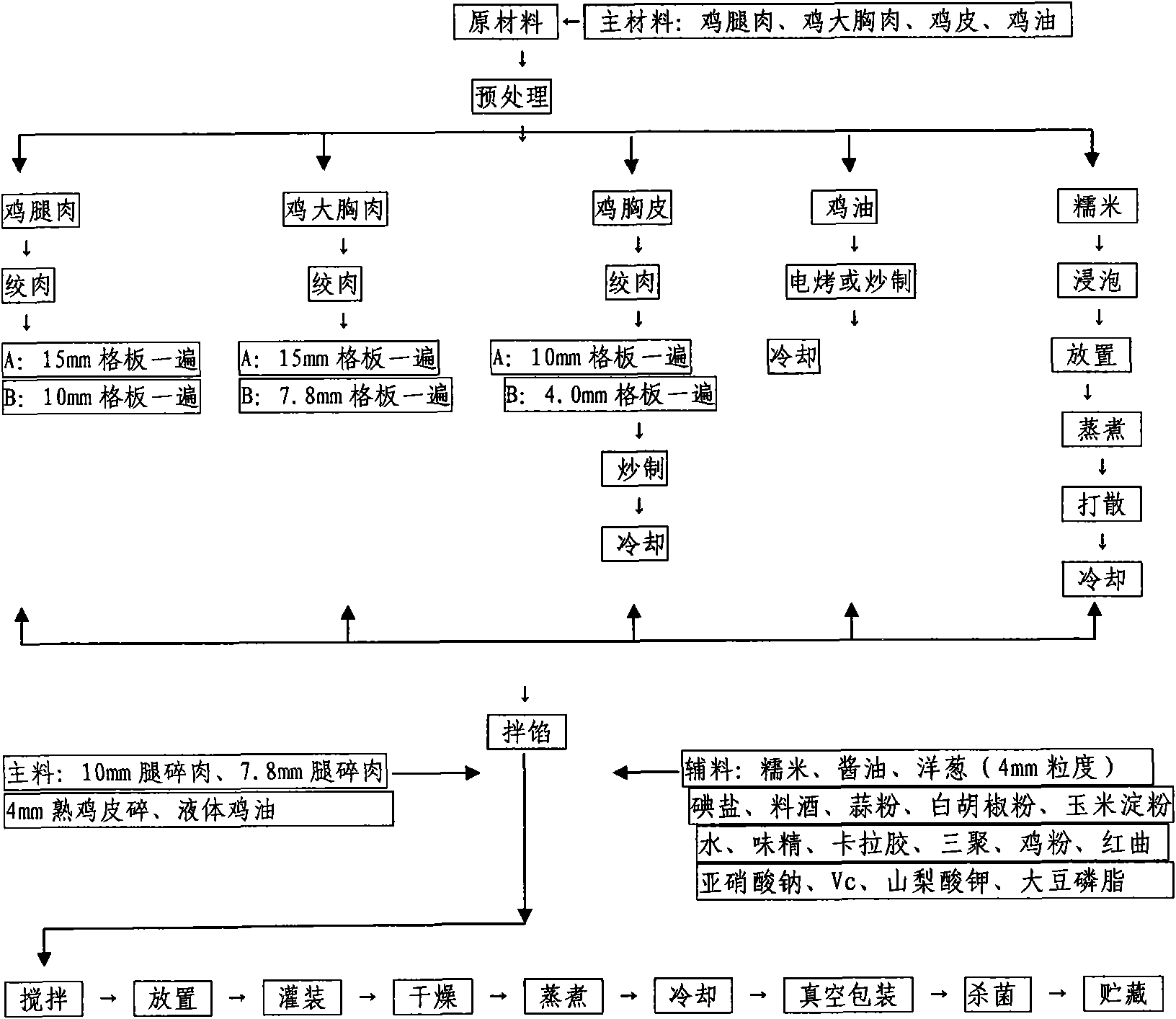

[0041] Example 1: Production of glutinous rice chicken sausage

[0042] The craft formula of glutinous rice chicken sausage is shown in Table 2. Fresh chicken and glutinous rice are used as raw materials. Chicken thigh meat and chicken breast meat are ground with 10mm and 7.8mm respectively, and then added with auxiliary materials and stirred evenly. Chicken skin is first ground with a 4mm grid plate and then fried. Just turn yellow. Chicken oil is heated into a liquid state using an oven or an induction cooker. Mix several meaty ingredients evenly and then add emulsifier first, and then add other auxiliary materials in sequence. The order of adding auxiliary materials is ①salt, sodium tripolyphosphate, sugar, MSG, carrageenan, 1 / 5 ice water; ②sodium nitrite, Vc, liquid red yeast rice, potassium sorbate, 1 / 5 ice water; ③soy sauce, cooking wine, 1 / 5 ice water; ④onion, white pepper, Garlic powder, chicken powder, 1 / 5 ice water; ⑤ cornstarch, 1 / 5 ice water; ⑥ steamed glutinous ri...

Embodiment 2

[0045] Embodiment 2: the making of oatmeal pork sausage

[0046] The technical formula of oatmeal pork sausage is shown in Table 3. Fresh pork and oatmeal are used as raw materials. The lean pork and fat meat are minced with 10mm and 6mm respectively and then added with auxiliary materials. The order of adding main and auxiliary materials is ①lean meat, fat meat, vegetable oil , emulsifier; ② salt, sodium tripolyphosphate, sugar, monosodium glutamate, carrageenan, 1 / 5 ice water; ③ sodium nitrite, Vc, liquid red yeast rice, potassium sorbate, 1 / 5 ice water; ④ soy sauce, cooking wine , 1 / 5 ice water; ⑤ onion, white pepper powder, garlic powder, chicken powder, 1 / 5 ice water; ⑥ cornstarch, 1 / 5 ice water; ⑦ oatmeal; After uniformity, continue to place at 0-4°C, place for 12-15 hours before filling, use 5-way pig casings for filling, tie a knot with a length of 10cm, and then hang the rod for drying. The drying condition is 70°C. 30-45 minutes, and then steamed at 85°C, steamed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com