Vacuum curing rolling method of meat products

A technology for vacuum marinating and meat products, which is applied in food preparation, food preservation, meat/fish preservation, etc., can solve the problems of reduced bite of meat quality, high production cost, and large tissue damage, and achieves tenderness. Improvement, simple process, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

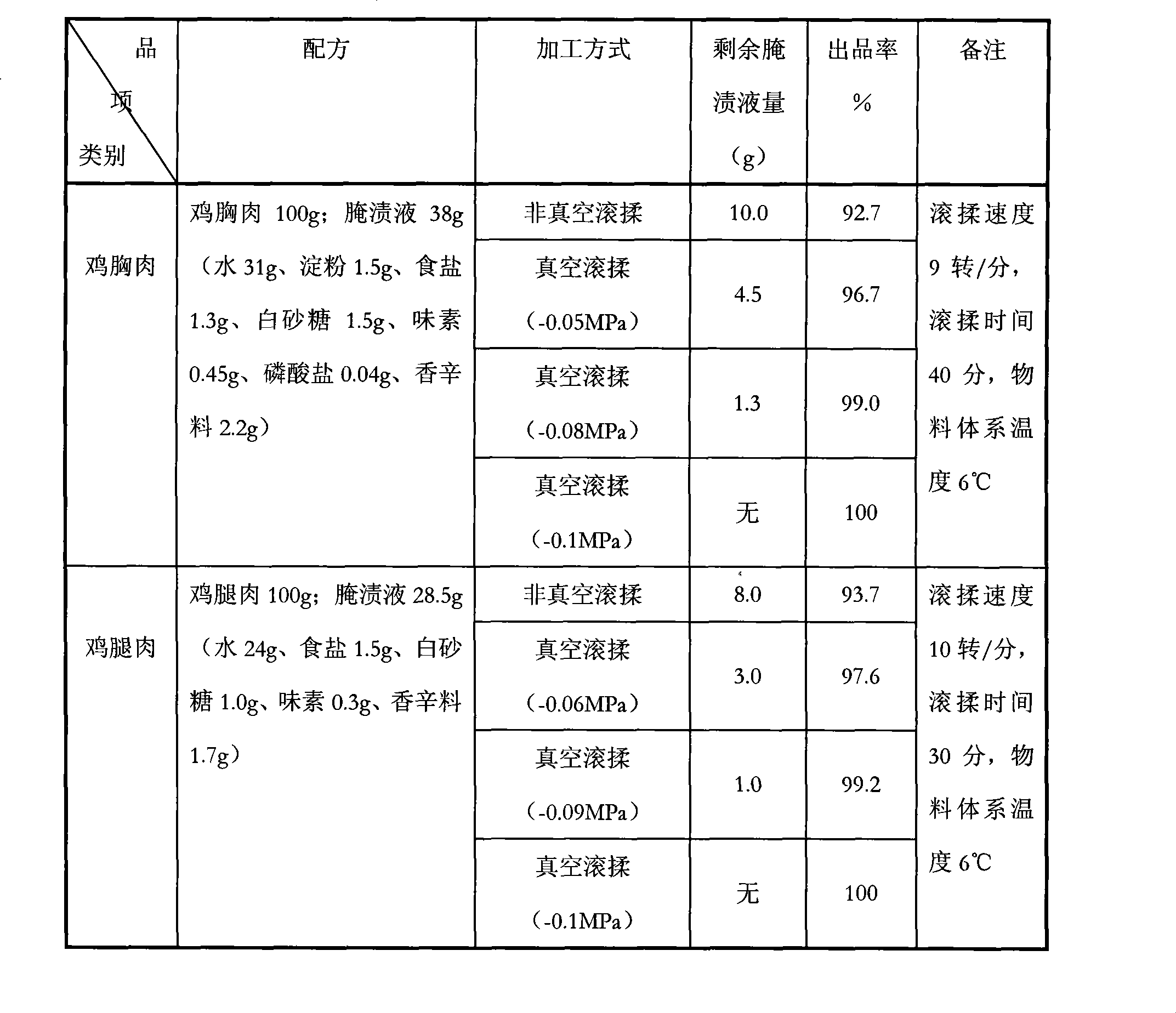

[0014] The invention uses meat and pickling liquid as raw materials, and through vacuuming and negative pressure rolling, the meat and pickling liquid are fully combined, formed together, and difficult to separate again.

[0015] Take chicken breasts and drumsticks, for example. Wherein the pickling liquid adopted for chicken breast is a combination of drinking water, starch, salt, white granulated sugar, monosodium glutamate, phosphate and spices; Compositions.

[0016] The specific process steps are as follows:

[0017] 1. Fully stir the weighed pickling solution to make it fully dispersed and dissolved evenly, and set aside;

[0018] 2. Pour the meat and the prepared pickling solution into the tumbler and pre-mix for 1 to 2 minutes;

[0019] 3. Seal the tumbler and evacuate until the pressure inside the machine is -0.05~-0.10Mpa;

[0020] 4. Set the speed of the tumbler to 4-13 rpm;

[0021] 5. Start tumbling, the tumbling time is 20-90 minutes;

[0022] 6. After tumb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com