Method for detecting vanadium valence in vanadium oxide

A detection method, vanadium oxide technology, applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of inaccurate detection results, complicated operation, etc., and achieve high dissolution efficiency, simple operation, and no particle size effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

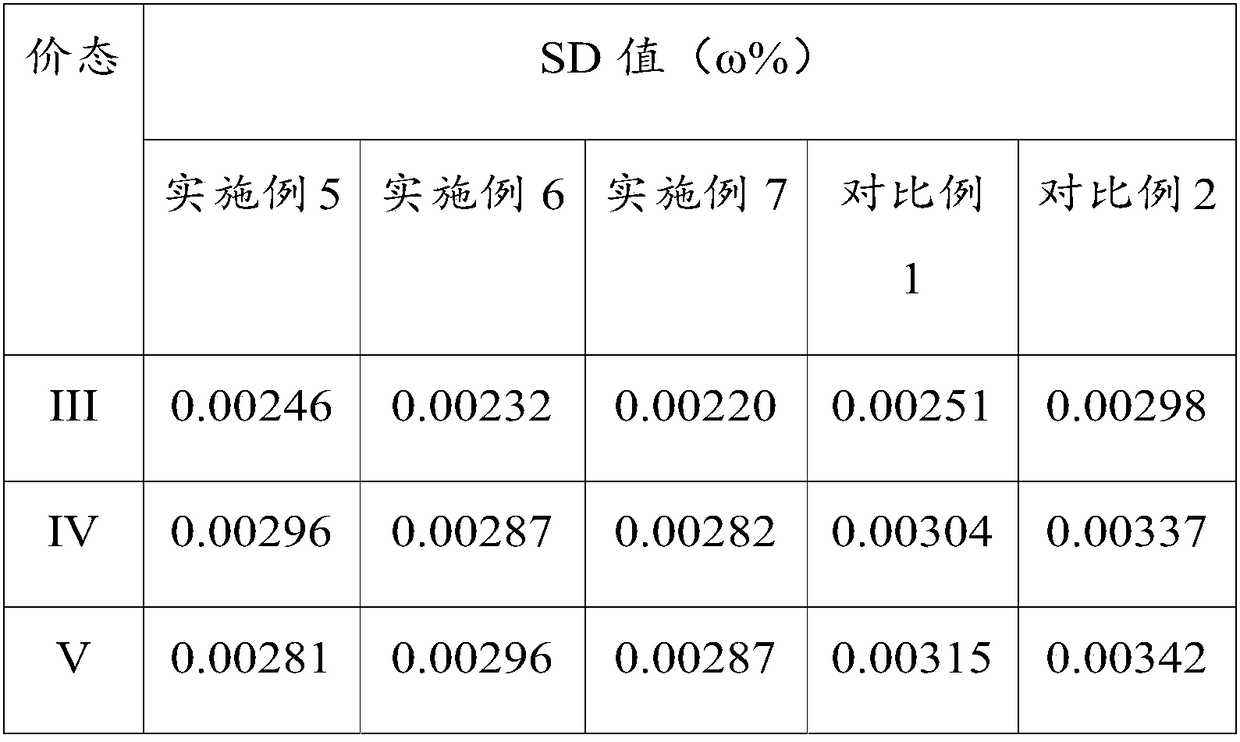

Examples

Embodiment 1

[0026] A method for detecting the valence state of vanadium in vanadium oxide provided in this embodiment, a method for detecting the valence state of vanadium in vanadium oxide, comprising:

[0027] After mixing the analyte and the solvent, use the high-pressure microwave digestion method to isolate the air and dissolve to obtain the sample solution; microwave heating for 15 minutes.

[0028] Next, the starch was compressed under a pressure of 300 MPa. Wherein, the weight ratio of the analyte to the starch is 0.1:2.

[0029] Next, drop 450 μL of the sample solution onto a filter paper with a diameter of 24 mm, and dry it at 40° C.

[0030] Put the filter paper in the center of the base holder, and press it with a pressure of 300MPa to form a 250-mesh sample to be tested.

[0031] Finally, the samples to be tested were measured by XRF. Excited under the conditions of voltage 40kV and current 40mA, the instrument uses a 28mm aperture.

Embodiment 2

[0033] A method for detecting the valence state of vanadium in vanadium oxide provided in this embodiment, a method for detecting the valence state of vanadium in vanadium oxide, comprising:

[0034] After mixing the analyte and the solvent, use the high-pressure microwave digestion method to isolate the air and dissolve to obtain the sample solution; microwave heating for 20min.

[0035] Next, the starch was compressed under a pressure of 500 MPa. Wherein, the weight ratio of the analyte to the starch is 0.8:10.

[0036] Next, drop 600 μL of the sample solution onto a filter paper with a diameter of 24 mm, and dry it at 60° C.

[0037] Put the filter paper in the center of the base holder, and press it with a pressure of 450MPa to form a 350-mesh sample to be tested.

[0038] Finally, the samples to be tested were measured by XRF. Excited under the conditions of voltage 55kV and current 60mA, the instrument uses a 30mm aperture.

Embodiment 3

[0040] A method for detecting the valence state of vanadium in vanadium oxide provided in this embodiment, a method for detecting the valence state of vanadium in vanadium oxide, comprising:

[0041] After mixing the analyte and the solvent, use the high-pressure microwave digestion method to isolate the air and dissolve to obtain the sample solution; microwave heating for 15 minutes.

[0042] Next, the starch was pressed under a pressure of 4 MPa. Wherein, the weight ratio of the analyte to the starch is 0.2:3.

[0043] Next, drop 280 μL of the sample solution onto a filter paper with a diameter of 24 mm, and dry it at 40-60° C.

[0044] Put the filter paper in the center of the bottom holder, and press it with a pressure of 420MPa to form a 320-mesh sample to be tested.

[0045]Finally, the samples to be tested were measured by XRF. Excited under the conditions of voltage 48kV and current 58mA, the instrument uses a 29mm aperture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com