Color fixing and softening method for loose fibers

A loose fiber, super soft technology, applied in textiles and papermaking, textile material processing, liquid/gas/steam textile material processing, etc., can solve the problems of low effective absorption rate of additives, affecting industrial development, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] When utilizing the method provided by the invention to carry out color fixation to bulk fiber and be too soft, comprise following implementation steps:

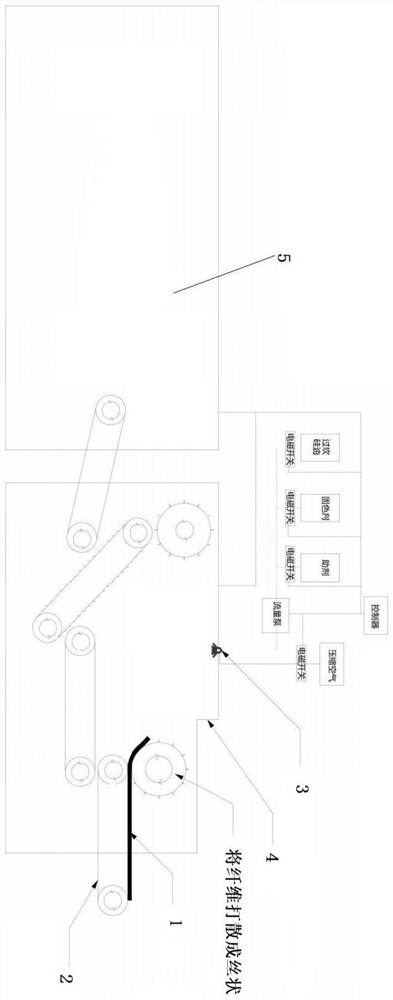

[0028] 1) placing the bulk fiber 1 to be processed on the belt 2 running horizontally;

[0029] 2) Use the atomizing injector 3 to pump the color fixing agent, oversoft silicone oil and additives into the atomizing device respectively, and heat them;

[0030] 3) Start the belt 2 to drive the loose fiber 1 to be processed into the box 4 of the opener, and the atomizing device atomizes the color fixing agent, oversoft silicone oil and additives to fill the box with atomized particles 4;

[0031] 4) Under the action of the atomizing airflow, the atomized particles start to fully and evenly stir with the loose fiber 1, and combine together, and the liquid-carrying rate of the loose fiber 1 rises to 5%;

[0032] 5) Under the action of wooden chains, the bulk fiber 1 is transported to the dryer 5 for drying, so as to real...

Embodiment 2

[0037] When utilizing the method provided by the invention to carry out color fixation to bulk fiber and be too soft, comprise following implementation steps:

[0038] 1) placing the bulk fiber 1 to be processed on the belt 2 running horizontally;

[0039] 2) Use the atomizing injector 3 to pump the color fixing agent, oversoft silicone oil and additives into the atomizing device respectively, and heat them;

[0040] 3) Start the belt 2 to drive the loose fiber 1 to be processed into the box 4 of the opener, and the atomizing device atomizes the color fixing agent, oversoft silicone oil and additives to fill the box with atomized particles 4;

[0041] 4) Under the action of the atomizing airflow, the atomized particles start to fully and evenly stir with the loose fiber 1, and combine together, and the liquid-carrying rate of the loose fiber 1 rises to 5%;

[0042] 5) Under the action of wooden chains, the bulk fiber 1 is transported to the dryer 5 for drying, so as to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com