Marinating and boiling equipment for beef processing and using method thereof

A technology of stewing and beef, applied in the direction of climate change adaptation, food science, etc., can solve the problems of mass production troubles and other problems, and achieve the effects of convenient mass production, reducing hot steam burns, and convenient and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

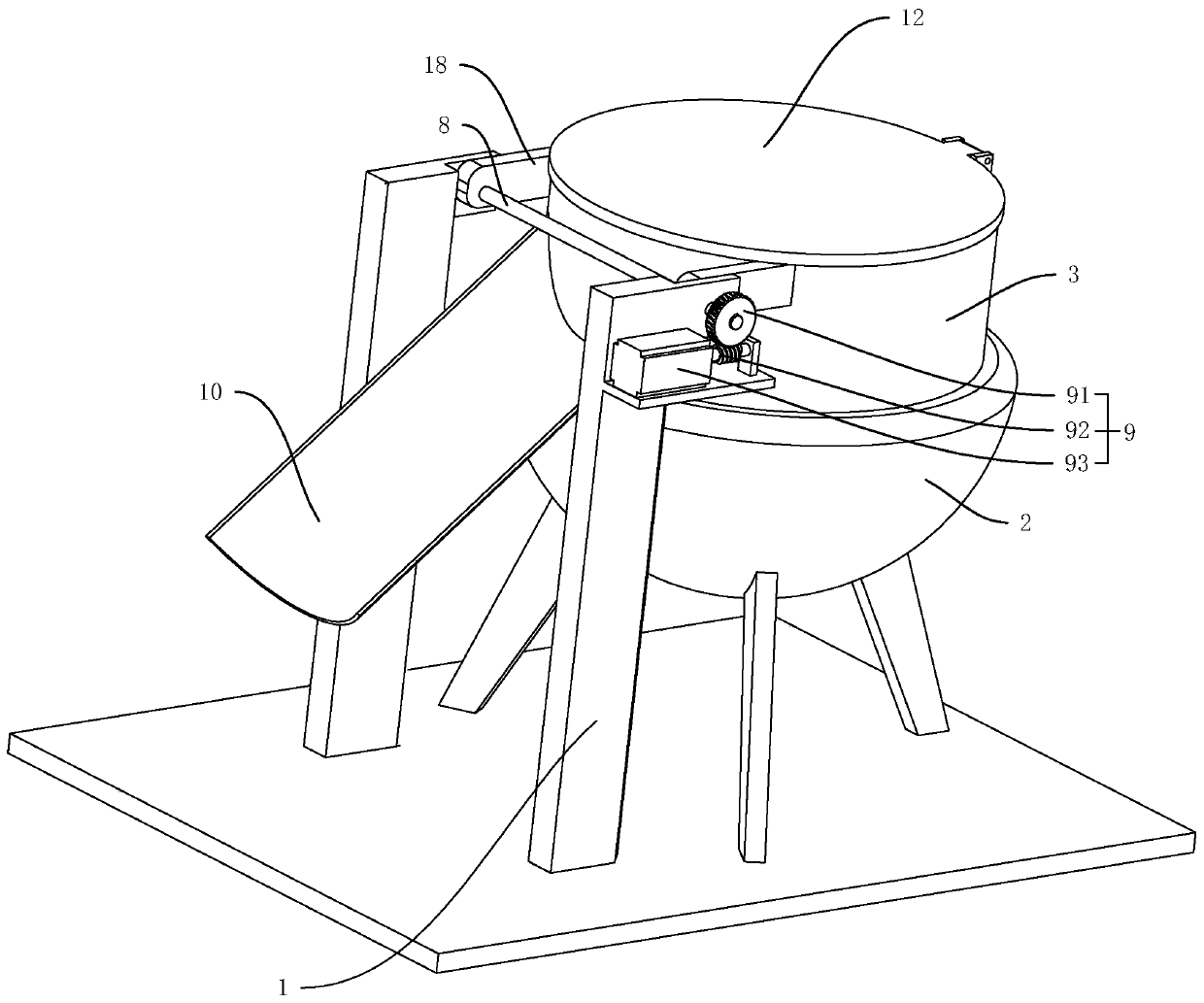

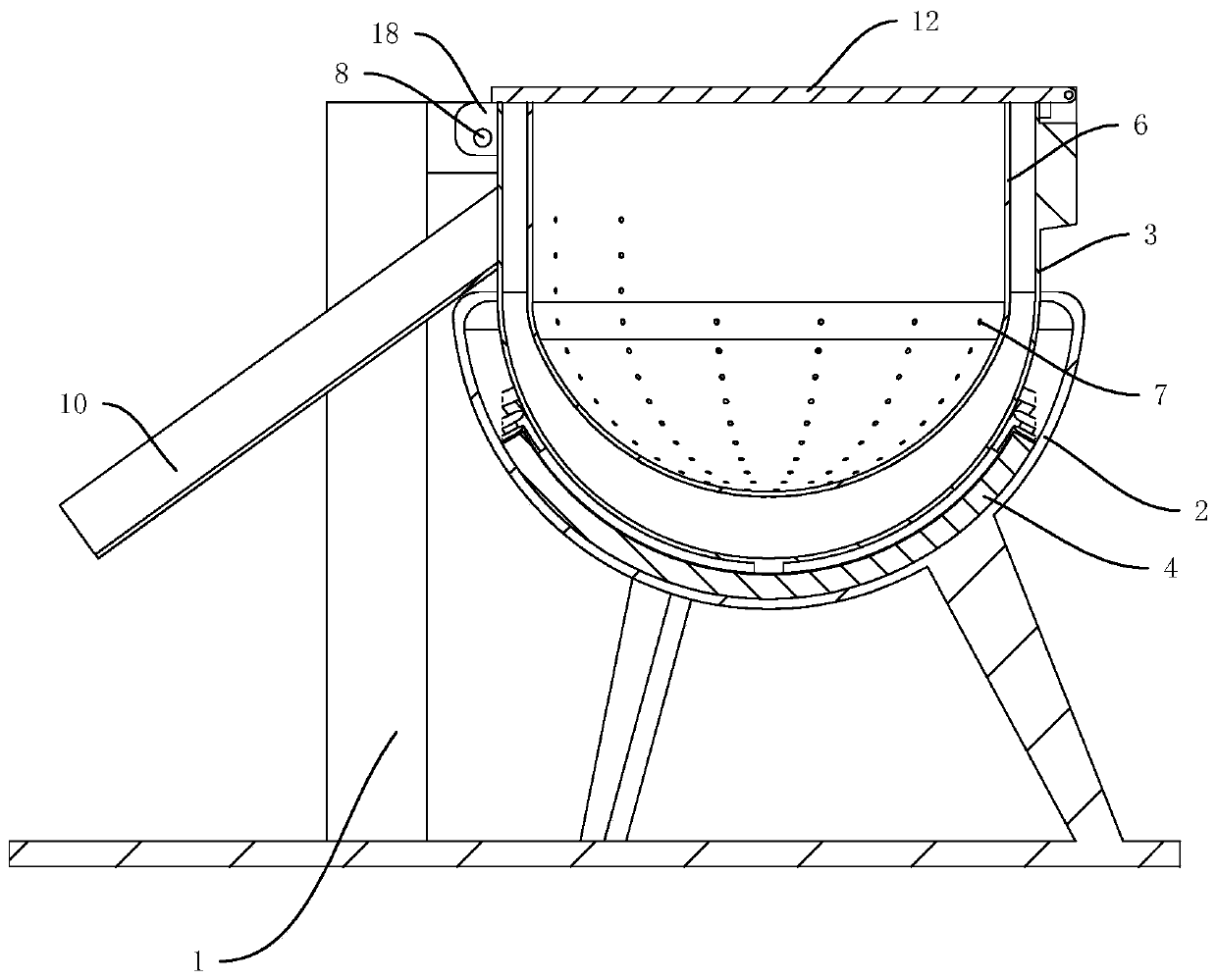

[0042] A kind of stewing equipment for beef processing, such as figure 1 , figure 2 As shown, it includes a support frame 1, a stewed cooking tank 2, a stewed cooking pot 3 and a heating device 4. The stewing tank 2 is fixed on the support frame 1, the heating device 4 is located in the stewing tank 2, and the heating device 4 is an electromagnetic heater.

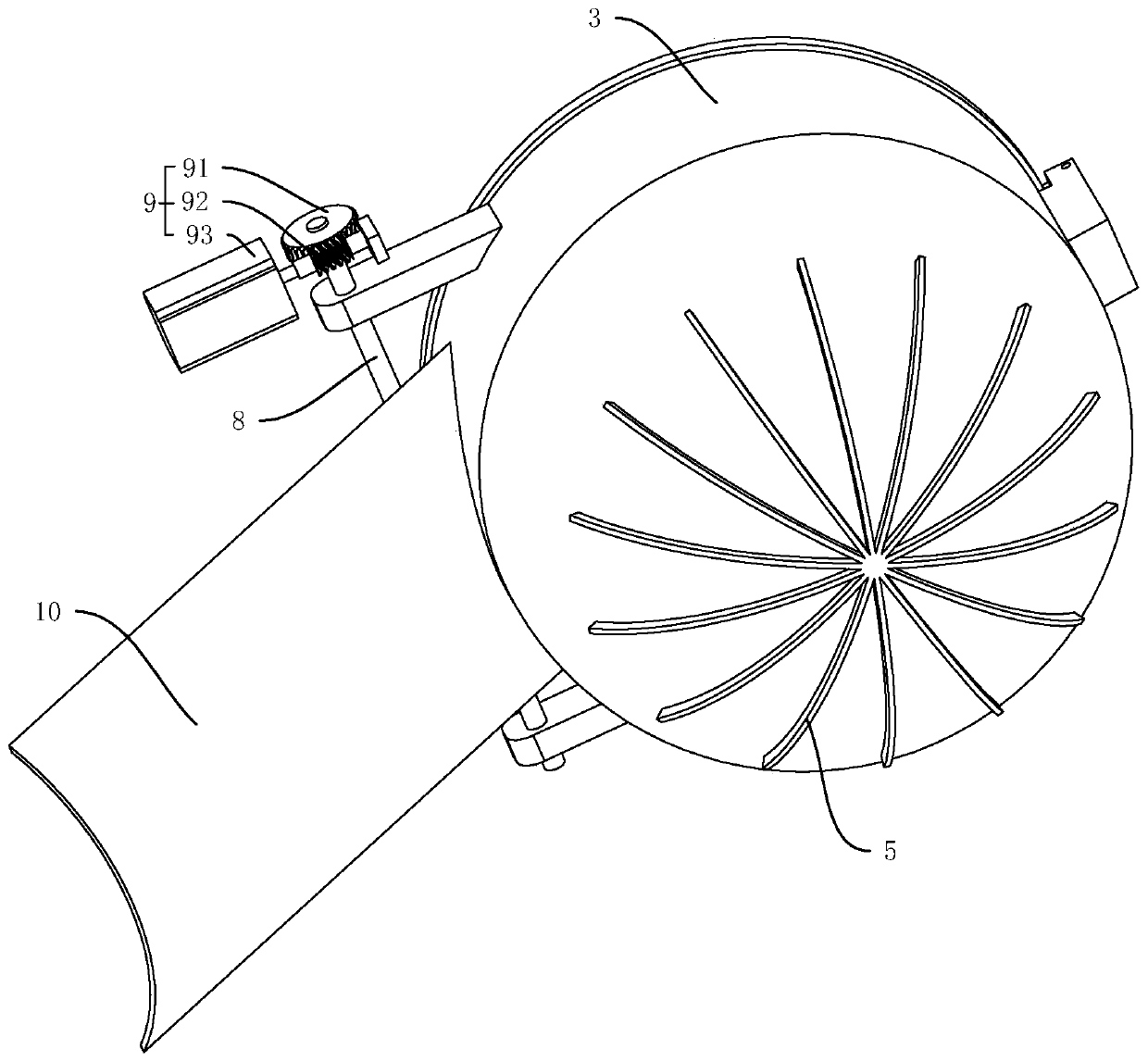

[0043] like figure 2 , image 3 As shown, the bittern cooking pot 3 is arranged in a cylindrical shape, the bottom of the stewed cooking pot 3 is arranged on a spherical surface, the stewed cooking pot 3 is fixed on the top of the stewed cooking tank 2 and above the heating device 4, and the lower end surface of the bottom of the stewed cooking pot 3 is fixed There are several steel fins 5, the steel fins 5 are arranged radially of the stewed cooking pot 3, and several steel fins 5 are evenly distributed along the circumferential direction of the stewed boiled pot 3.

[0044] Such as figure 1 , Figure 4 As shown, th...

Embodiment 2

[0052] A method for using stewing equipment for beef processing, comprising the following steps:

[0053] S1, add ingredients, the stewed inner pot 6 is in the state of the stewed pot 3, put the beef to be stewed into the stewed inner pot 6, then put the stewed material into the net box 14, and close the lid The pot cover 12 makes the net box 14 be located in the stewed cooking pot 3 and be positioned at the outside of the stewed boiled inner container 6 .

[0054] S2, cooking, start the heating device 4 to heat and cook, and cook for the required time according to actual needs.

[0055] S3, discharge, when the cooking is finished, the stewed inner pot 6 is turned over to the outside of the stewed pot 3 through the driving device 9, the stewed inner pot 6 can be turned over to drive the pot cover 12 to turn over, when the stewed inner pot 6 When the opening is turned upside down, the marinated beef is poured out.

[0056] Through the above operations, the influence of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com