Process for manufacturing sliced dried beef

A production process and technology of beef jerky, applied in the field of food processing, can solve the problems of beef jerky and not easy to chew, and achieve the effects of easy chewing and increasing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

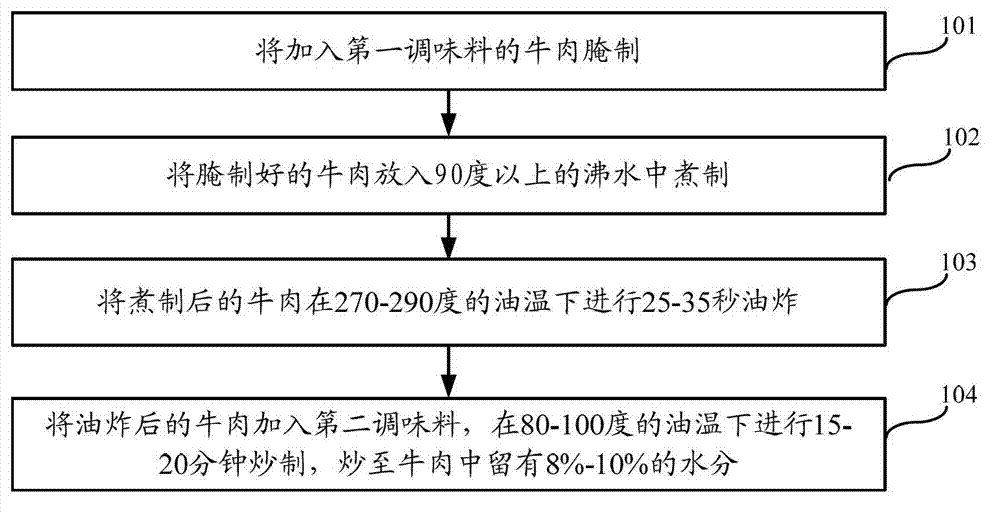

[0023] Embodiment 1: as figure 1 Shown, the manufacture craft of beef jerky, comprises the following steps:

[0024] Step 101, marinating the beef with the first seasoning;

[0025] Step 102, boil the marinated beef in boiling water above 90 degrees;

[0026] Step 103, frying the cooked beef at an oil temperature of 270-290 degrees for 25-35 seconds;

[0027] Step 104, adding the second seasoning to the fried beef, and frying it for 15-20 minutes at an oil temperature of 80-100 degrees until 8%-10% of water remains in the beef.

[0028] Marinate the beef with the first seasoning, and cook the marinated beef in boiling water above 90 degrees; the beef cooked in this way is already tasty, which is conducive to more fully dissolving the seasoning; After cooking, fry the beef at an oil temperature of 270-290 degrees for 25-35 seconds; due to the high temperature, the surface of the beef slices will quickly form a skin, so that the moisture inside the beef will not continue to l...

Embodiment 2

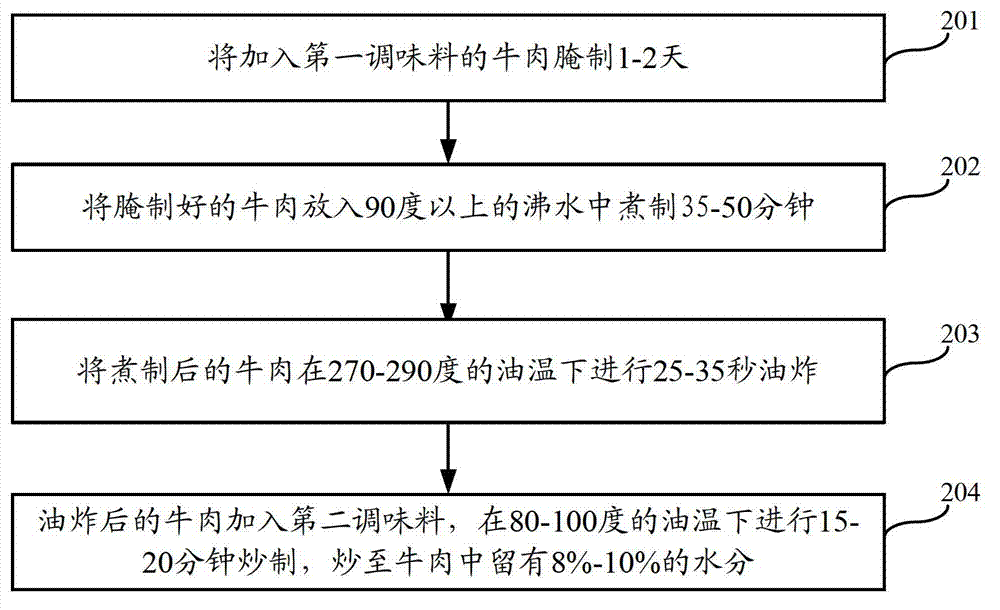

[0029] Embodiment 2: as figure 2 Shown, the manufacture craft of beef jerky, comprises the following steps:

[0030] Step 201, marinating the beef added with the first seasoning for 1-2 days;

[0031] Step 202, put the marinated beef into boiling water above 90 degrees and cook for 35-50 minutes;

[0032] Step 203, frying the cooked beef at an oil temperature of 270-290 degrees for 25-35 seconds;

[0033] Step 204, adding the second seasoning to the fried beef, and frying it for 15-20 minutes at an oil temperature of 80-100 degrees until 8%-10% of water remains in the beef.

[0034] Clean the beef. The first seasoning includes salt, sugar, cooking wine and sodium nitrite. Add 1000 grams of salt, 500 grams of sugar, 500 grams of cooking wine and 0.03-0.05 grams per 50 kilograms of beef. Sodium nitrite, and fully mixed with the cleaned beef to marinate. Wherein adding trace sodium nitrite 0.03-0.05 gram, can keep the color and luster bright of the beef after marinating, als...

Embodiment 3

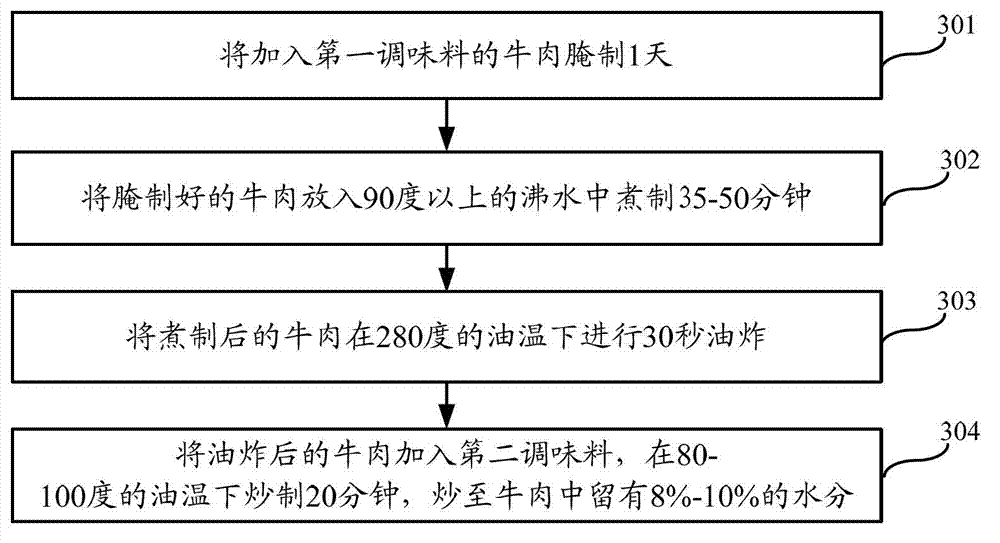

[0044] Embodiment 3: as image 3 As shown, when making beef jerky in summer, due to the influence of the ambient temperature, the production process of beef jerky will be somewhat different, including the following steps:

[0045] Step 301, marinating the beef added with the first seasoning for one day;

[0046] Step 302, put the marinated beef into boiling water above 90 degrees and cook for 35-50 minutes;

[0047] Step 303, frying the cooked beef at an oil temperature of 280-285 degrees for 25-30 seconds;

[0048] Step 304, adding the second seasoning to the fried beef, frying at an oil temperature of 80-100°C for 15-20 minutes, until 8%-10% of water remains in the beef.

[0049] Clean the beef. The first seasoning includes salt, sugar, cooking wine and sodium nitrite. Add 1000 grams of salt, 500 grams of sugar, 500 grams of cooking wine and 0.03-0.05 grams per 50 kilograms of beef. Sodium nitrite, and fully mixed with the cleaned beef to marinate. Wherein adding trace s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com