Processing method for improving quality of dried beef

A processing method and technology of beef jerky, which is applied in the field of food processing, can solve the problems of endangering the health of eaters, high content of carcinogens, heavy smoke of beef jerky, etc., and achieve the effects of improving appetite, long shelf life, and long aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

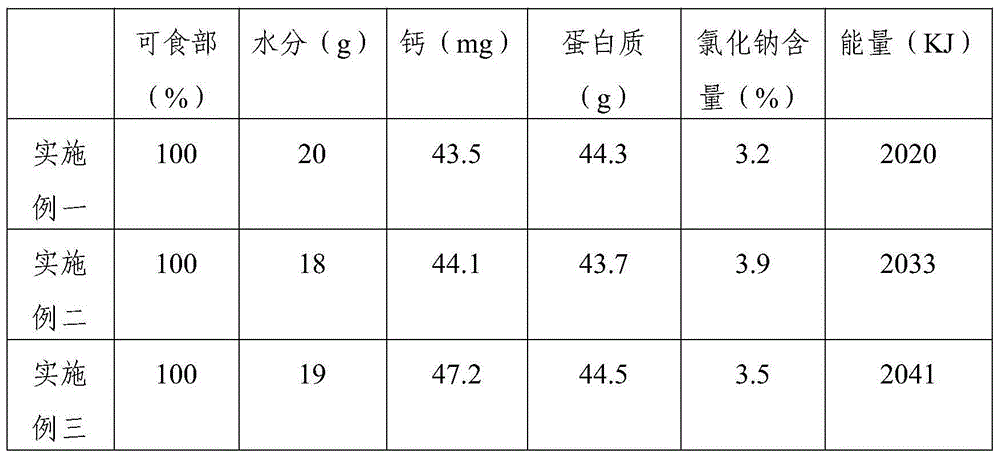

Examples

Embodiment 1

[0024] A processing method for improving the quality of beef jerky, comprising the following steps:

[0025] (1) Preparation of culture solution: mix peptone, beef extract, sodium chloride, and agar according to a certain amount, sterilize at a temperature of 120°C for 20 minutes, then add water to adjust its pH value to 6 to obtain a culture solution. The mass ratio of peptone, beef extract, sodium chloride and agar is 6:10:5:15;

[0026] (2) Beef pretreatment: select the beef that has passed the hygienic inspection. In the first step, after removing the bone, fascia and fat, cut it into long strips of 40cm, 10cm in width and 8cm in thickness; in the second step, Wash the long strips of beef with warm water at a temperature of 20°C; in the third step, put the strips of beef after washing in a layered pot, and boil them in water at a temperature of 60°C for 10 minutes; in the fourth step, boil the strips in water After the beef strips are cut into thin slices of 3cm in length...

Embodiment 2

[0031] A processing method for improving the quality of beef jerky, comprising the following steps:

[0032] (1) Preparation of culture solution: mix peptone, beef extract, sodium chloride, and agar according to a certain amount, sterilize at 130° C. for 10 minutes, and then add water to adjust its pH to 7 to obtain a culture solution. The mass ratio of beef extract, sodium chloride and agar is 8:12:6:20;

[0033] (2) Beef pretreatment: select the beef that has passed the hygienic inspection. In the first step, after removing the bone, fascia and fat, cut it into long strips of 60cm, 15cm in width and 10cm in thickness; in the second step, Wash the long strips of beef with warm water at a temperature of 30°C; in the third step, put the strips of beef after washing in a layered pot, and boil them in water at a temperature of 80°C for 5 minutes; in the fourth step, boil the strips in water After the beef strips are cut into 5cm, 3cm wide and 0.9cm thick slices;

[0034] (3) Fe...

Embodiment 3

[0038] A processing method for improving the quality of beef jerky, comprising the following steps:

[0039] (1) Preparation of culture solution: mix peptone, beef extract, sodium chloride, and agar according to a certain amount, sterilize at a temperature of 125°C for 15 minutes, then add water to adjust its pH to 6.5 to obtain a culture solution; the peptone , The mass ratio of beef extract, sodium chloride and agar is 7:11:5.5:18;

[0040] (2) Beef pretreatment: select the beef that has passed the hygienic inspection. In the first step, after removing the bone, fascia and fat, cut it into long strips of 50cm, 12cm in width and 9cm in thickness; in the second step, Wash the long strips of beef with warm water at a temperature of 25°C; in the third step, put the strips of beef after cleaning in a layered pot, and boil them in water at a temperature of 70°C for 8 minutes; in the fourth step, boil the strips in water After the beef strips are cut into thin slices of 4cm, 2.5cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com