Peanut vegetarian meat ham and production method thereof

A production method and peanut-based technology, which are applied in the field of food processing, can solve the problems that the taste does not conform to ordinary consumers, are expensive, and are inconvenient to eat, and achieve the effects that amino acid matching tends to be reasonable, convenient to eat, and convenient to transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

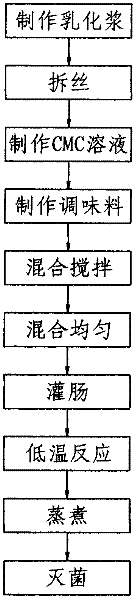

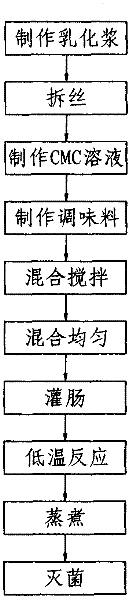

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: a kind of peanut vegan meat ham, its raw material composition according to weight is composed of: dried peanut thick silk tissue protein 13%, soybean protein 2.5%, gluten 2.5%, potato starch 5.8%, vegetable oil 10%, complex With konjac gum 0.35%, salt 1%, monosodium glutamate 1%, sugar 1.2%, spices 1.5%, CMC 0.3%, calcium carbonate 0.7%, water 60.15%. Among them, the compound konjac gum is formed by compounding carrageenan and konjac gum at a weight ratio of 1:2; the spices are compounded at a weight ratio of white pepper powder: nutmeg: five-spice powder at a weight ratio of 2:1:0.5.

[0031] Its specific production steps are:

[0032] (1) Making emulsified slurry: Add water and soybean protein into the emulsifier at one time, turn the speed to the highest level, stir for 85 seconds, then slowly add vegetable oil, and continue to add vegetable oil for 50 seconds, and then stop the machine after stirring for 8 seconds. After the emulsified pulp i...

specific Embodiment approach 2

[0043] A kind of peanut meat ham, its raw material composition according to weight is as follows: 13% of dried peanut thick silk tissue protein, 2.5% of soybean protein, 2.5% of gluten powder, 5.8% of potato starch, 10% of vegetable oil, 0.35% of compound konjac gum , salt 1%, monosodium glutamate 1%, sugar 1.2%, spices 1.5%, CMC 0.3%, calcium carbonate 0.7%, water 60.15%. Among them, the compound konjac gum is formed by compounding carrageenan and konjac gum at a weight ratio of 1:2; the spices are compounded at a weight ratio of white pepper powder: nutmeg: five-spice powder at a weight ratio of 2:1:0.5.

[0044] Its specific production steps are:

[0045] (1) Making emulsified slurry: Add water and soybean protein into the emulsifier at one time, turn the speed to the highest level, stir for 90 seconds, then slowly add vegetable oil, and continue to add vegetable oil for 60 seconds, and then stop the machine after stirring for 10 seconds. After the emulsified pulp is made,...

specific Embodiment approach 3

[0056] A kind of peanut meat ham, its raw material composition according to weight is as follows: 13% of dried peanut thick silk tissue protein, 2.5% of soybean protein, 2.5% of gluten powder, 5.8% of potato starch, 10% of vegetable oil, 0.35% of compound konjac gum , salt 1%, monosodium glutamate 1%, sugar 1.2%, spices 1.5%, CMC 0.3%, calcium carbonate 0.7%, water 60.15%. Among them, the compound konjac gum is formed by compounding carrageenan and konjac gum at a weight ratio of 1:2; the spices are compounded at a weight ratio of white pepper powder: nutmeg: five-spice powder at a weight ratio of 2:1:0.5. Its specific production steps are:

[0057] (1) Making emulsified slurry: Add water and soybean protein into the emulsifier at one time, turn the speed to the highest level, stir for 95 seconds, then slowly add vegetable oil, and continue to add vegetable oil for 70 seconds, and then stop the machine after stirring for 12 seconds. After the emulsified pulp is made, the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com