Mixer shaft of hard ice cream machine

A technology of hard ice cream and stirring shaft, which is applied in the field of hard ice cream machines, can solve the problems of reduced cooling speed and cooling uniformity, poor ice cream taste, slow heat dissipation of freezing cylinder, etc., so as to improve cooling uniformity, improve uniformity, reduce The effect of working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the preferred embodiments shown in the accompanying drawings.

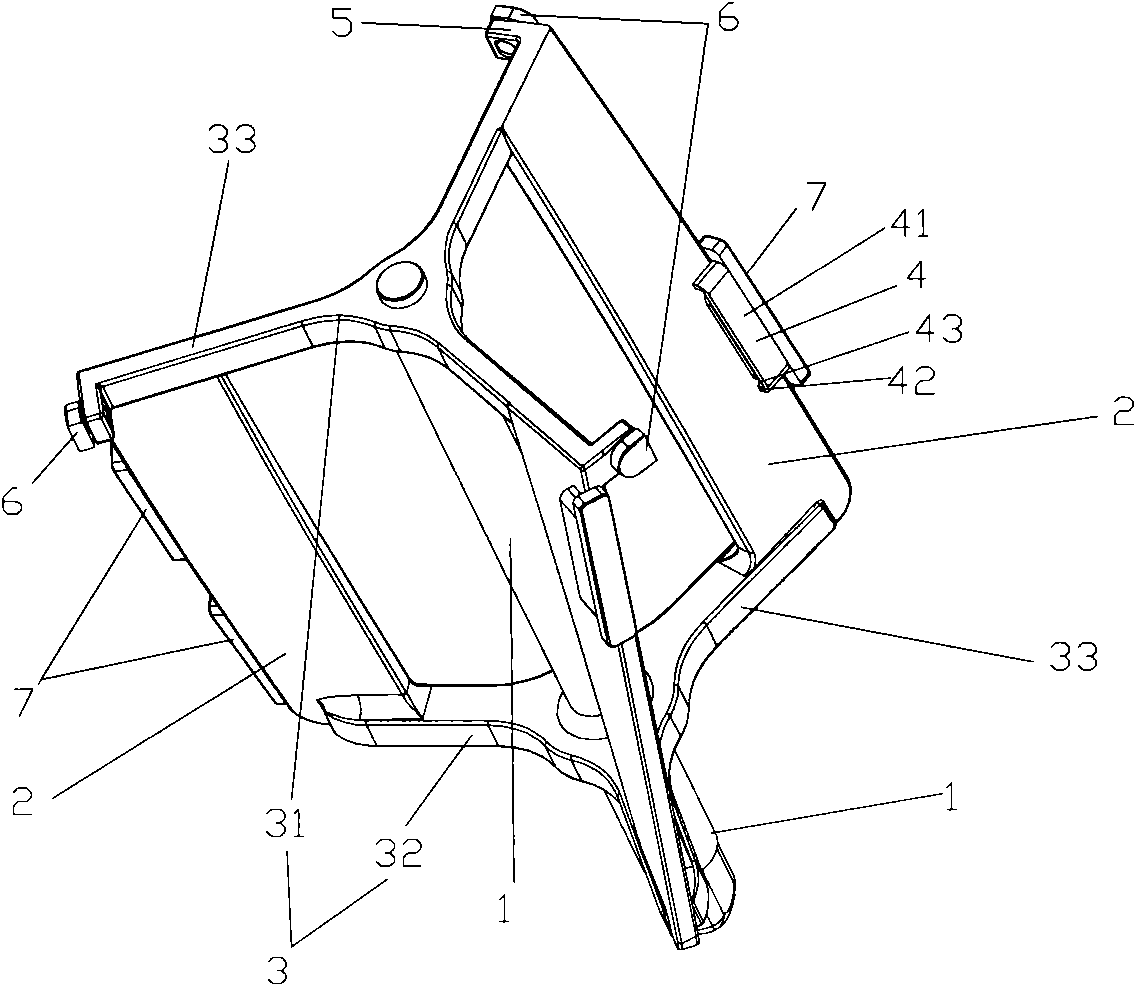

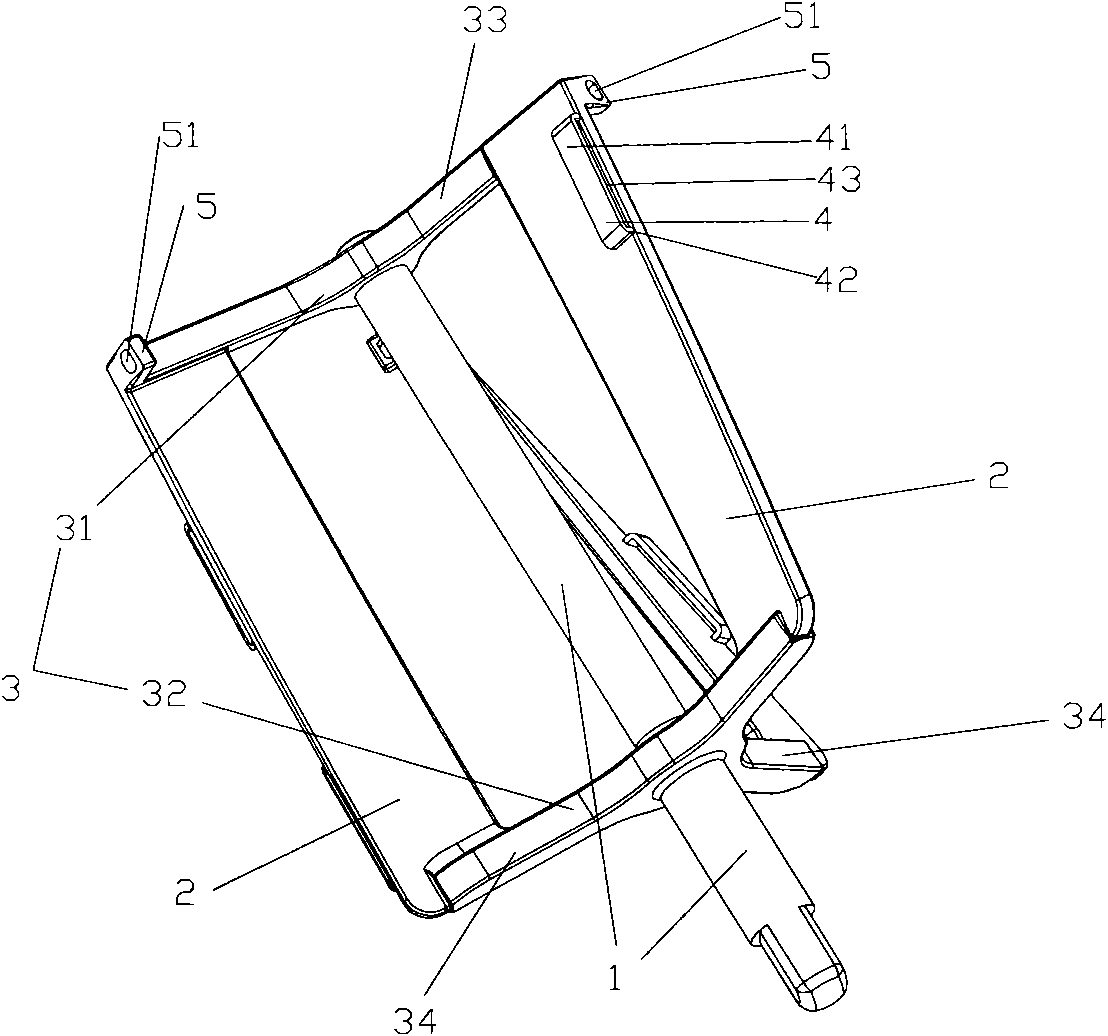

[0026] Hard ice cream machine stirring shaft of the present invention, as figure 1 and figure 2 As shown, it includes a central rotating shaft 1, a rotating body 3 arranged on the central rotating shaft 1 and a stirring blade 2 arranged on the rotating body 3, a scraper 7 is arranged on the outer edge of the stirring blade 2, and the scraping blade 7 is arranged on The stirring blades 2 have different heights and can slide along the stirring blades 2 in the radial direction of the stirring shaft. The lower end of the central rotating shaft 1 is provided with a connecting end for connecting a power system. The stirring blade 2 is helical around the central rotating shaft 1 .

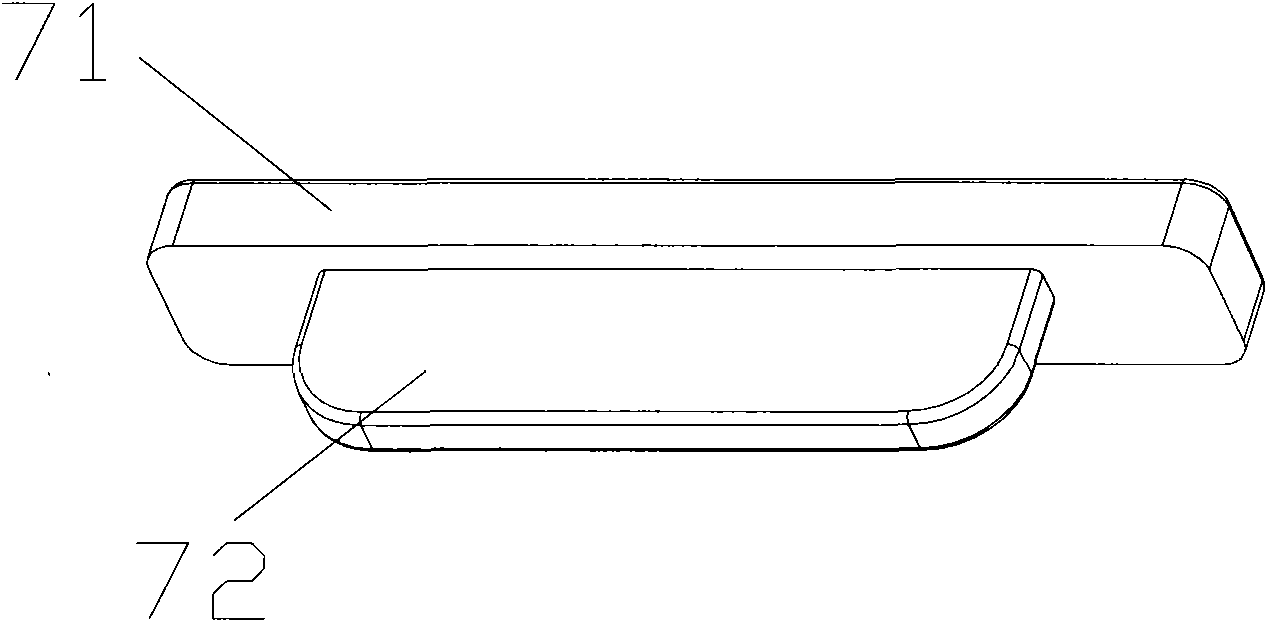

[0027] Such as figure 1 , figure 2 and image 3 As shown, the stirring blade 2 is provided with lugs 4 at different heights. The lug 4 includes a lug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com