Refrigeration control method of ice cream machine

An ice cream machine, refrigeration control technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of inability to adjust refrigeration capacity, inability to meet ice cream machine molding control and energy saving requirements, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

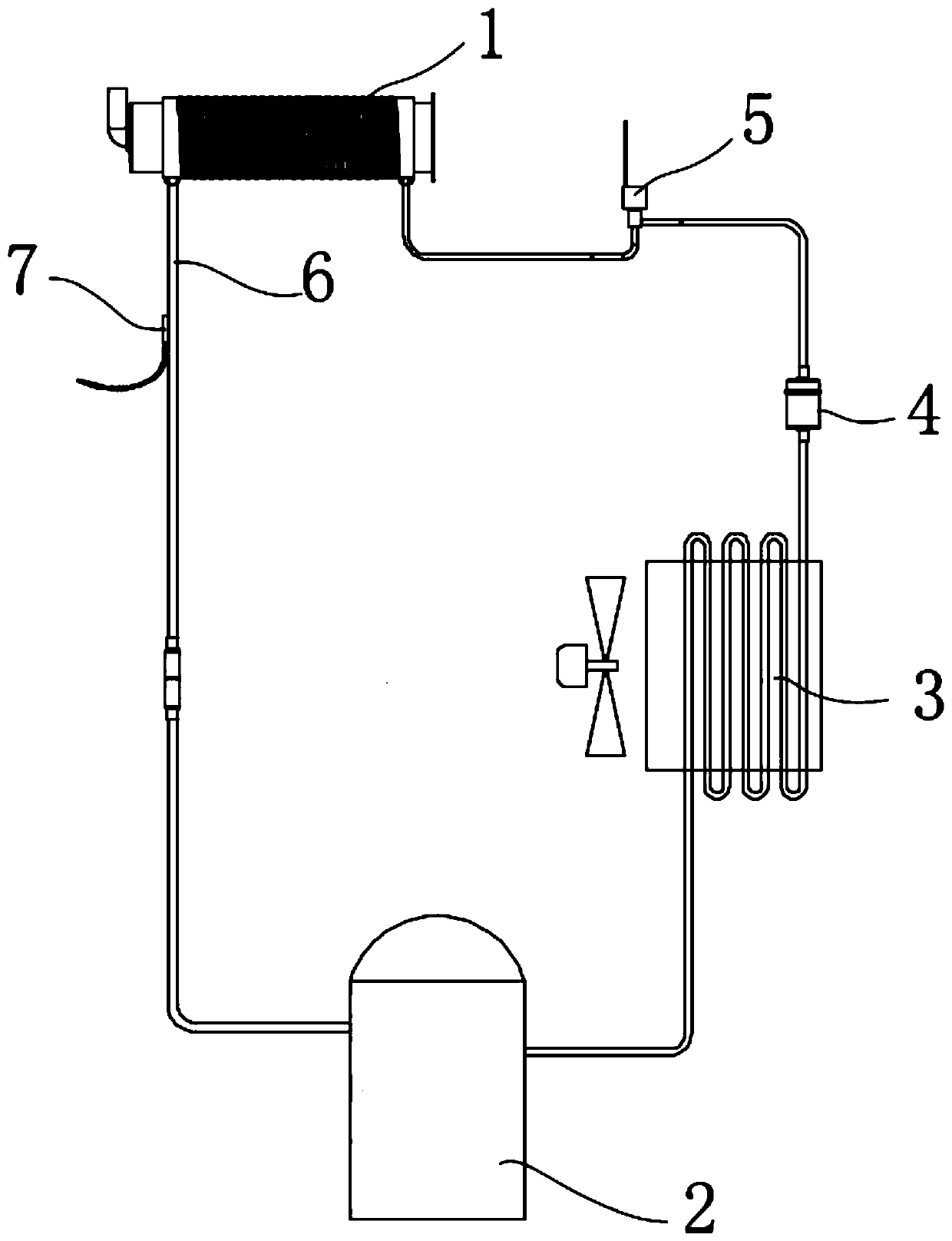

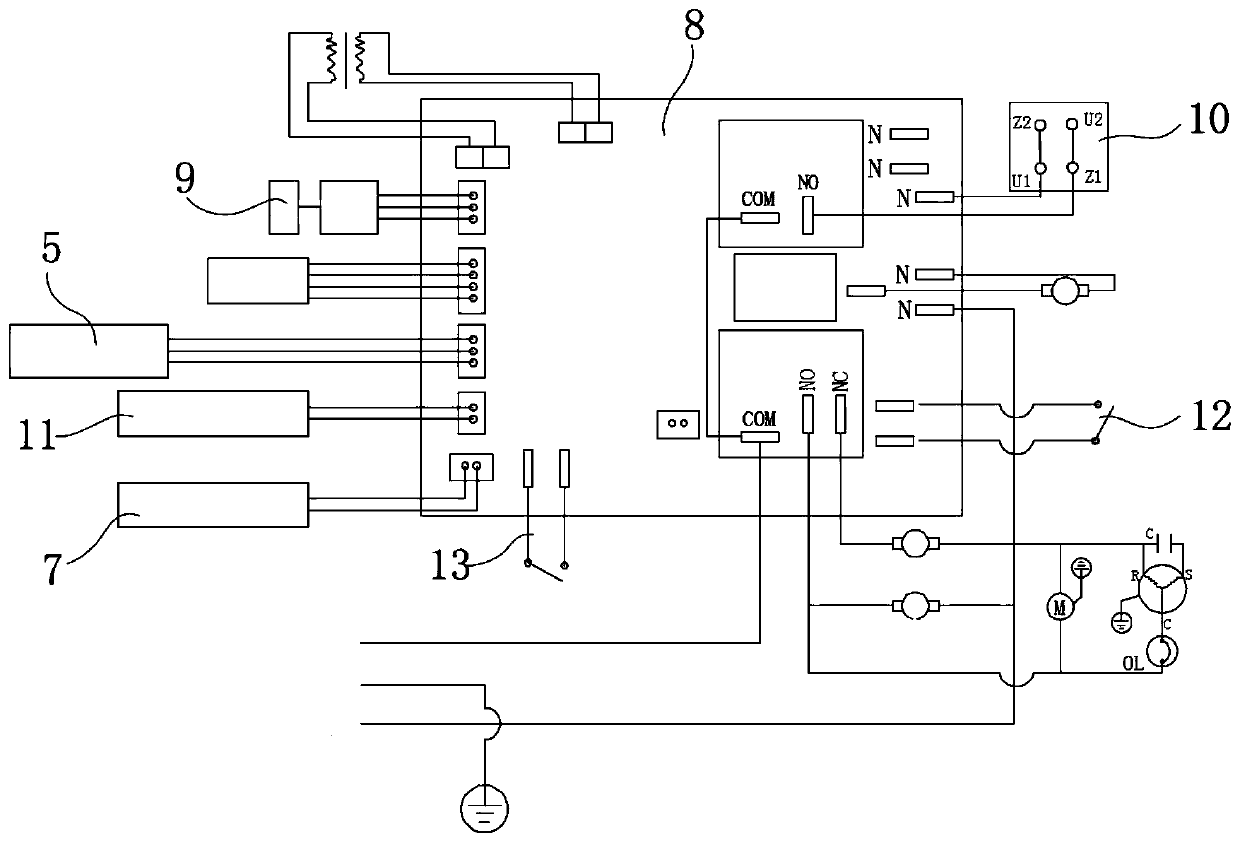

[0041] The ice cream machine of the present invention includes a freezing cylinder with a stirrer, a main refrigeration system and a control system, such as figure 1 As shown, the main refrigeration system includes a refrigeration circuit composed of a compressor 2, a condenser 3, a throttling device, and an evaporator 1 connected by a refrigeration pipeline. A filter is installed on the refrigeration pipeline between the throttling device and the condenser 3. 4, the control system controls the operation of the ice cream machine, including controlling the main refrigeration system to cool the ice cream in the freezing cylinder and controlling the agitator to stir, the throttling device is an electronic expansion valve 5, so The control system is also used to obtain the real-time forming degree value of the ice cream material in the freezing cylinder, and to feedback control the valve opening degree of the electronic expansion valve 5 through the forming degree value;

[0042] The...

Embodiment 2

[0050] The difference from the first embodiment is that this embodiment reflects the difference between the real-time forming degree value of the ice cream material in the freezing cylinder and the initial value of the forming degree through the change of the rotation speed value of the working motor of the mixer. That is, in this embodiment, the valve opening of the electronic expansion valve 5 is adjusted by feedback of the rotational speed value of the working motor of the agitator. During the forming process when the ice cream material in the freezing cylinder changes from liquid state to solid-liquid mixed state to solid state, until it reaches the final hardness / viscosity preset by the control system, the current value of the working motor of the agitator will gradually increase, and The speed value will gradually decrease according to this changing law. The real-time forming degree value of the ice cream material in the freezing cylinder can be judged by the rotational s...

Embodiment 3

[0053] The difference from Embodiment 1 and Embodiment 2 is that this embodiment reflects the difference between the real-time forming degree value of the ice cream material in the freezing cylinder and the initial value of the forming degree through the change of the evaporation temperature value in the main refrigeration system. The evaporation temperature value is the evaporation temperature of the evaporator in the main refrigeration system.

[0054] When the ice cream machine is working in each gear, the forming value of the ice cream material in the freezing cylinder gradually increases with the decrease of the evaporation temperature. According to this change rule, the ice cream in the freezing cylinder can be obtained by collecting the real-time evaporation temperature value in the main refrigeration system The molding degree value of the material.

[0055] In this embodiment, the control system presets a set of evaporation temperature thresholds X for each gear. 1~n , Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com