Pop-top can flattening equipment

A technology of cans and equipment, applied in the field of cans flattening equipment, can solve the problems of affecting people's normal use, inconvenient use of a small amount of cans, and failure to meet the needs of use, so as to achieve simple structure, meet the needs of use, and improve extrusion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

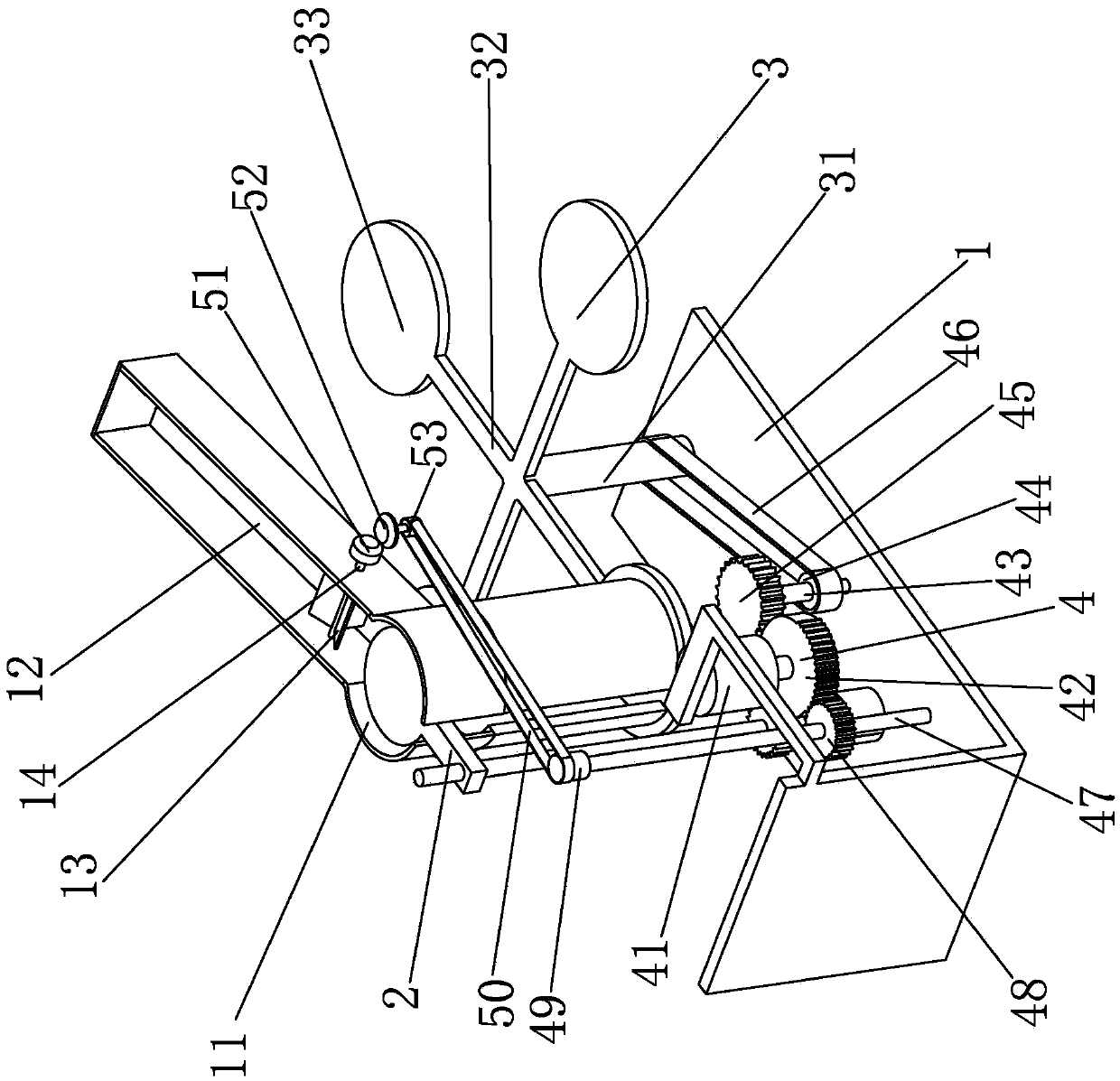

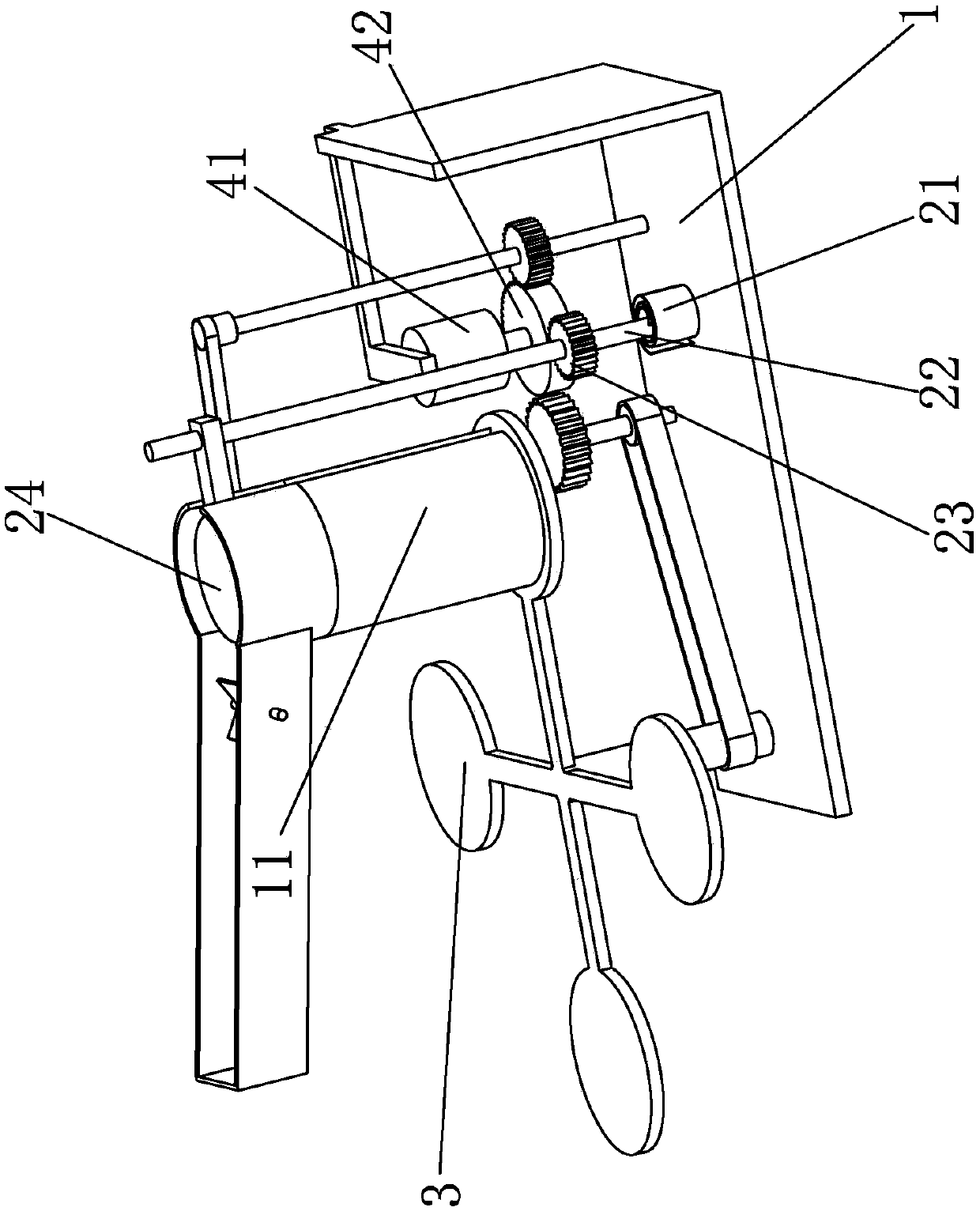

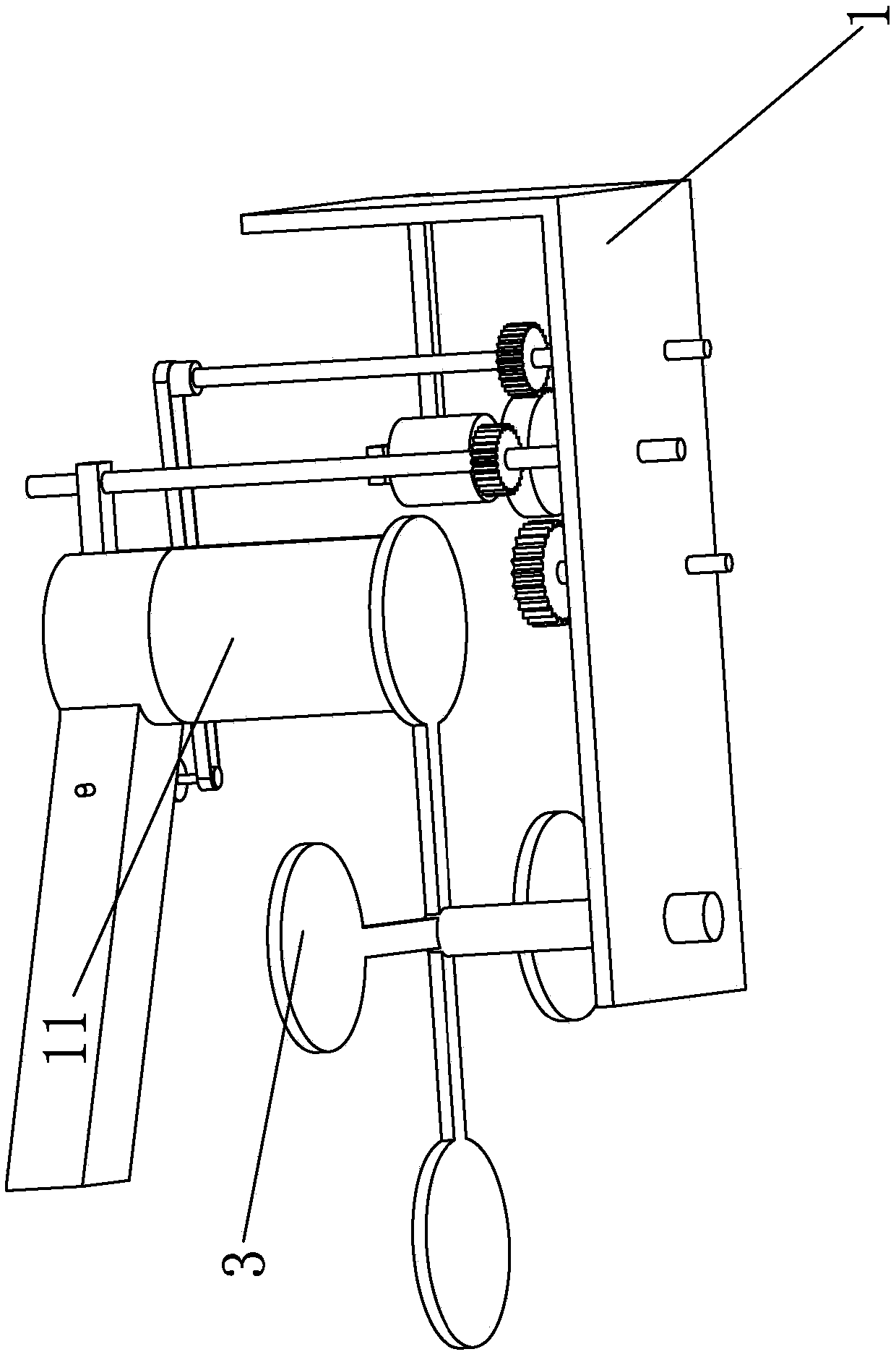

[0016] Such as Figures 1 to 3 The shown one can crushing equipment includes a fixed seat 1, an extrusion cylinder 11 that penetrates up and down at the upper end of the fixed seat 1, and a feeding channel for placing pop cans is provided on the upper end side of the extrusion cylinder 11. 12. The front end of the feeding channel 12 is provided with a turning plate 13 capable of turning the can into the extrusion cylinder 11 through the insertion shaft 14, and a flap 13 is provided at the upper end of the extrusion cylinder 11 to squeeze the can into the extrusion cylinder 11. The pressing device 2 is provided with a closing device 3 capable of sealing the lower end of the extruding cylinder 11 at the lower end of the extruding cylinder 11, and is provided with a closing device 3 on the fixed seat 1 that can firstly drive the flap 13 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com