Novel inching horizontal type extrusion clipper

A shearing machine and inching technology, applied in the direction of shearing devices, shearing machine equipment, large fixed members, etc., can solve the problems of slow extrusion, easy shearing, and difficult feeding, and achieve fast extrusion and easy shearing , the effect of convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

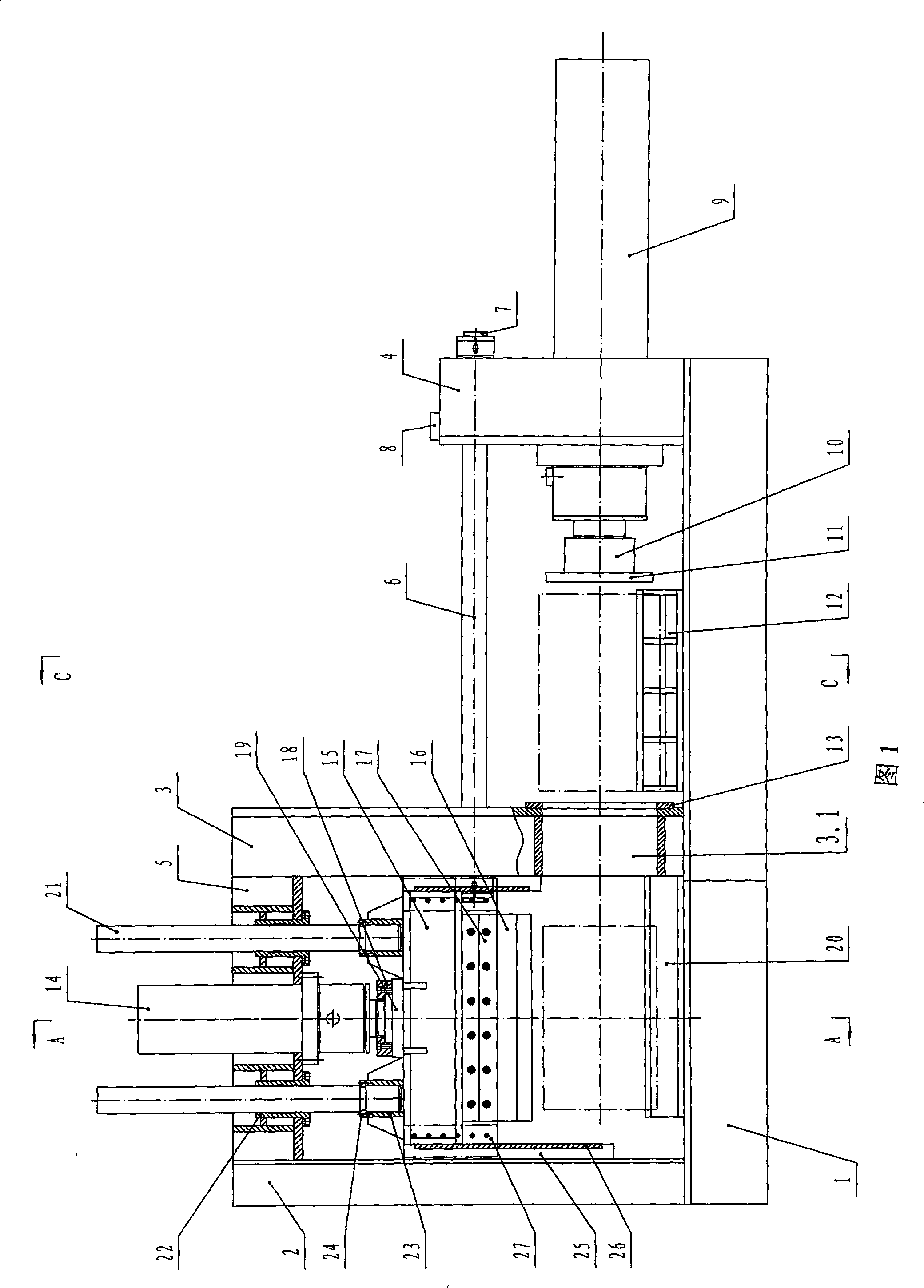

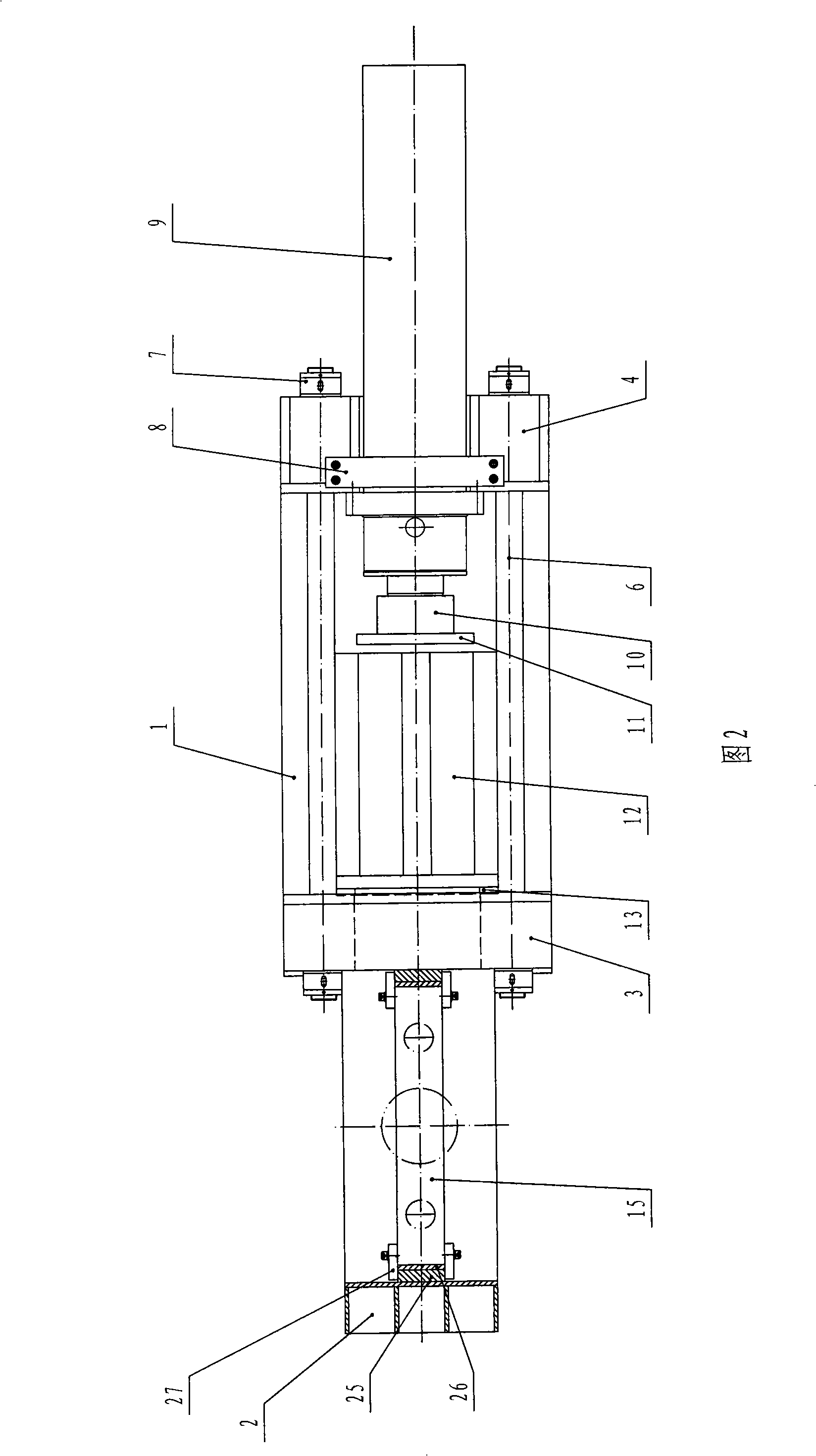

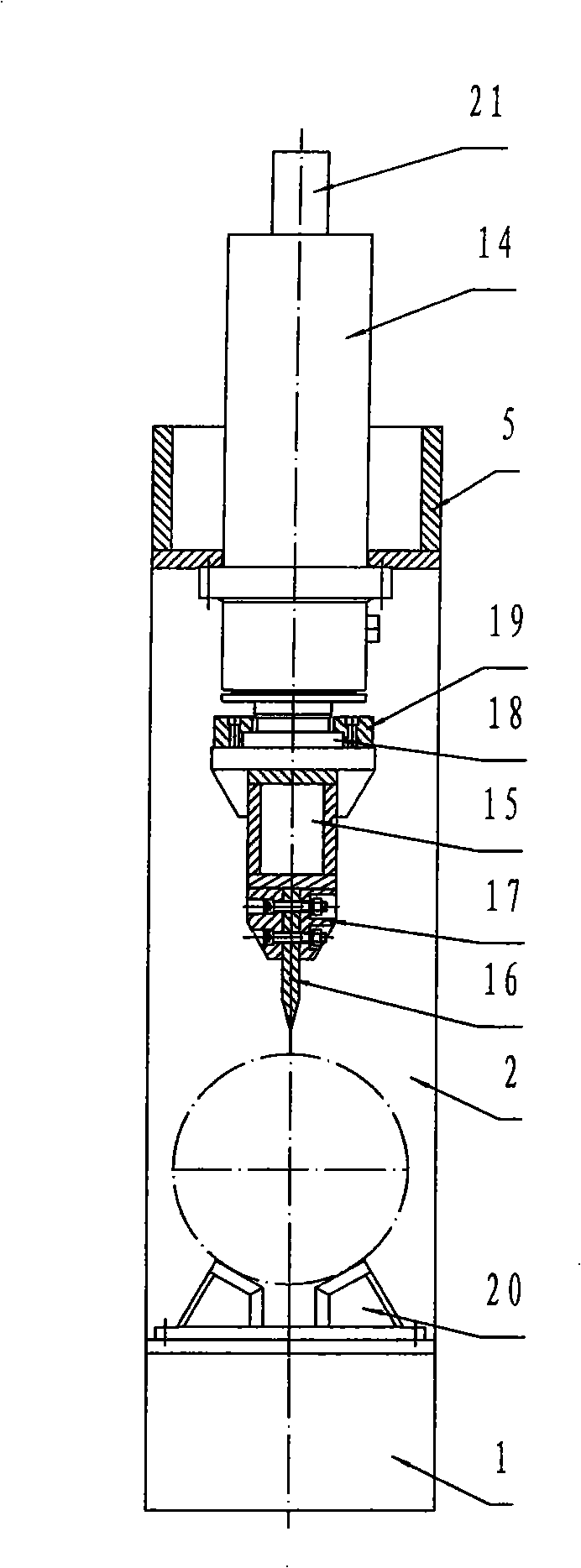

[0017] Referring to Figures 1 to 4, the novel point-moving horizontal extrusion shearing machine related to the present invention is mainly composed of a frame, an extrusion device, a shearing device, a guide device, a hydraulic system and an electrical control system.

[0018] Described frame is formed a frame structure by base 1, first vertical wall board 2, second vertical wall board 3, the third vertical wall board 4, upper beam 5 and tie rod 6. The first vertical wall panel 2, the second vertical wall panel 3, and the third vertical wall panel 4 are vertically installed on the base 1 from left to right, and the upper beam 5 is horizontally connected to the first vertical wall panel. Between the wallboard 2 and the second vertical wallboard 3, the pull rod 6 is transversely connected between the second vertical wallboard 3 and the third vertical wallboard 4. tight. A reinforcing plate 8 is arranged on the top of the third vertical wall panel 4 . A horizontal channel 3.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com