Twin-screw compression straw baler

A twin-screw, baler technology, applied in the direction of balers, harvesters, agricultural machinery and implements, etc., can solve the problems of left and right weight imbalance, complex baler structure, large power consumption, etc., to achieve convenient distribution of ropes Spacing, easy to compress into stacks, improve the effect of compression density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

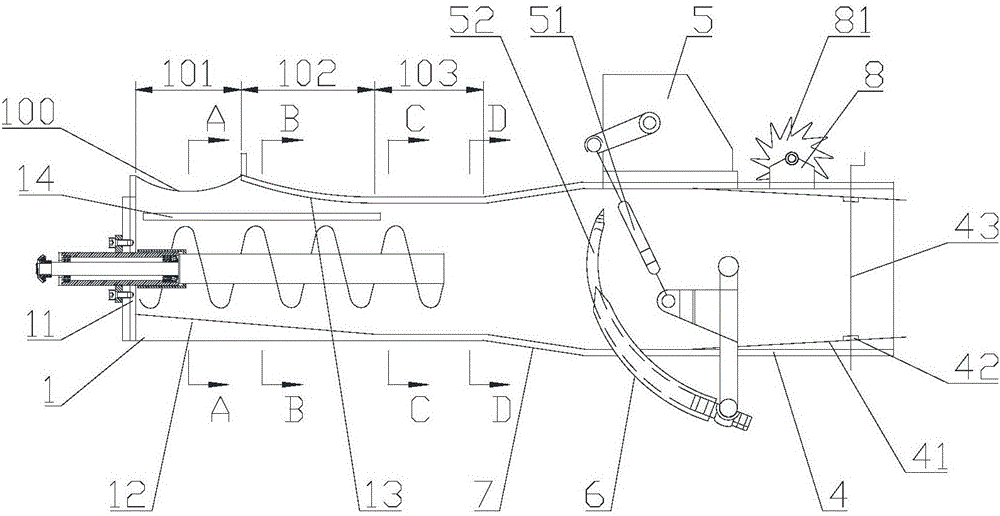

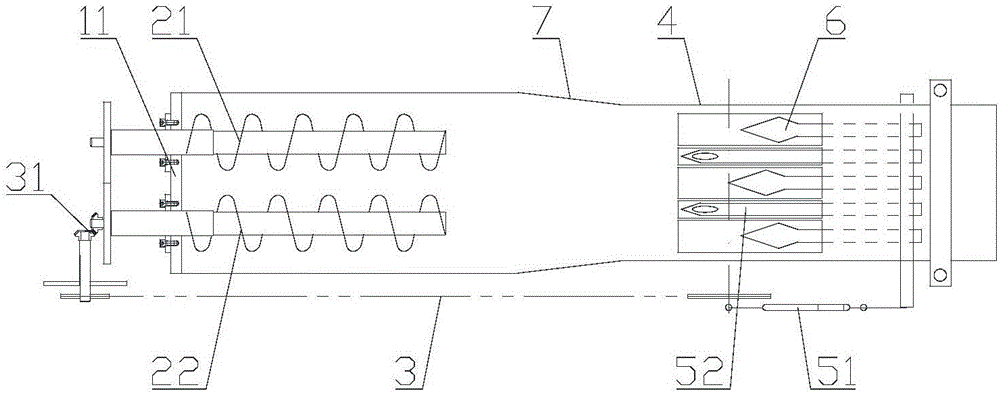

[0024] Such as Figures 1 to 7 As shown, the present invention provides a twin-screw compression straw baler.

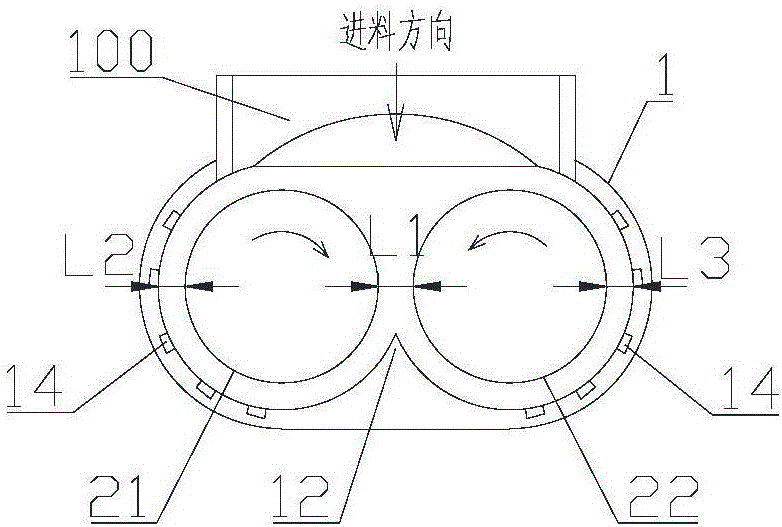

[0025] See figure 1 and figure 2 , the present invention includes a twin-screw straw compressor, a bundling device and a driving device, the twin-screw straw compressor includes a material barrel 1, a first helical blade 21 and a second helical blade 22, the material barrel 1 is provided with a feed port 100, the second A helical blade 21 and a second helical blade 22 are arranged side by side in the barrel 1, and the barrel 1 communicates with the bundling device and conveys and compresses straw to the bundling device through the first helical blade 21 and the second helical blade 22. A helical blade 21 and a second helical blade 22 are driven by a driving device, the helical directions of the first helical blade 21 and the second helical blade 22 are opposite, and the rotation directions of the first helical blade 21 and the second helical blade 22 are opposite....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com