High-efficient glazer

A kind of polishing machine, high-efficiency technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding machine parts, etc., can solve the problems of easy scratches, high plate pressure, low cutting speed, etc., to avoid scratches No scratches and edge collisions, strong bearing capacity, and good rotational rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail by the following examples.

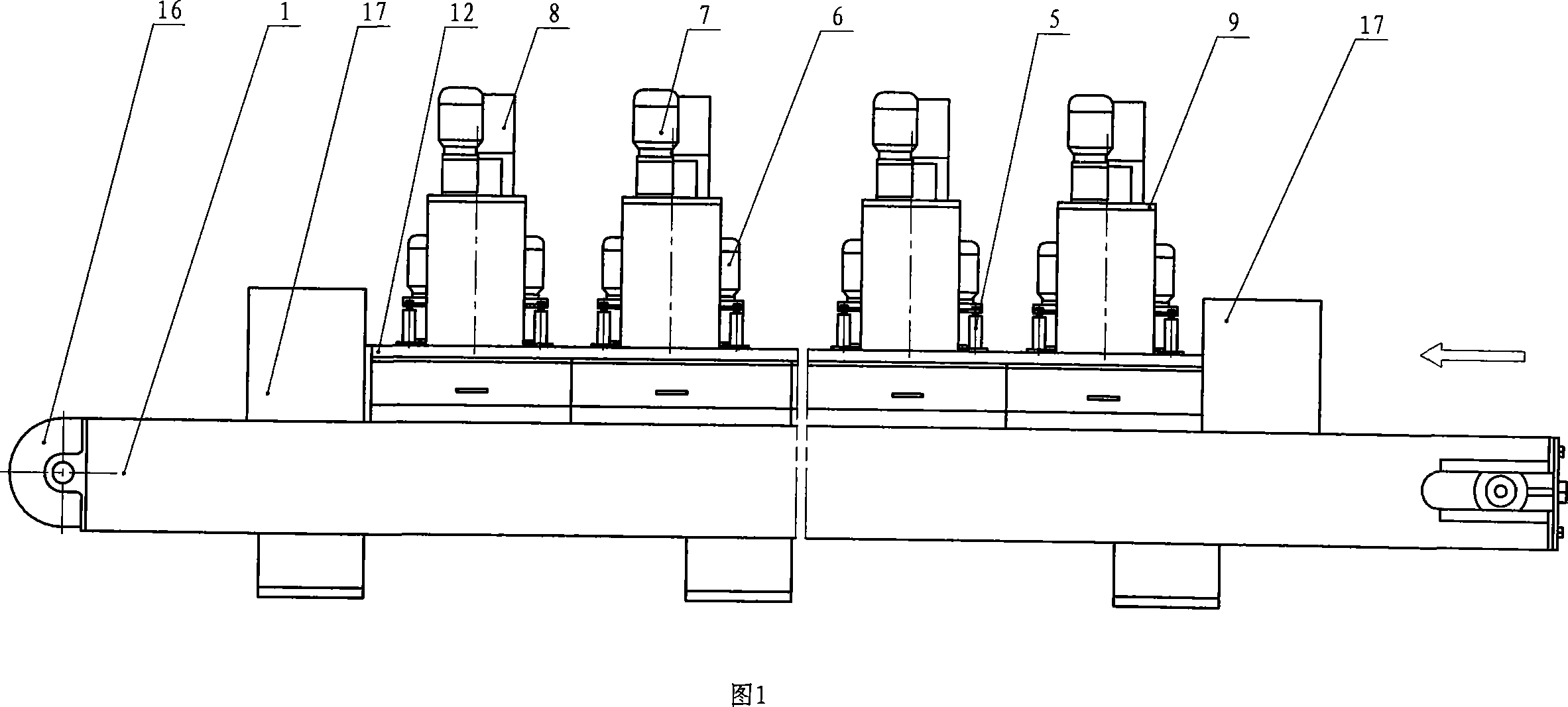

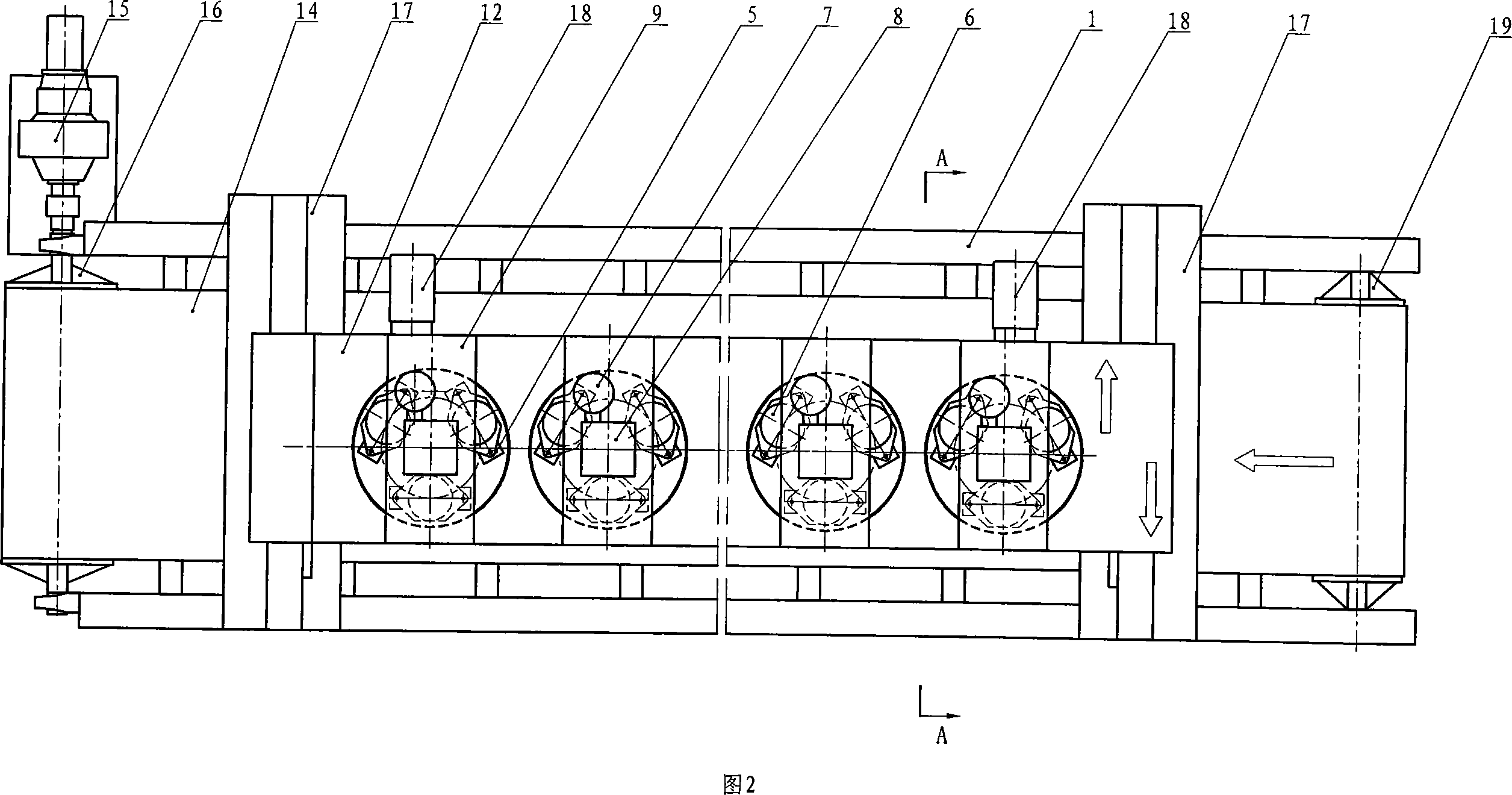

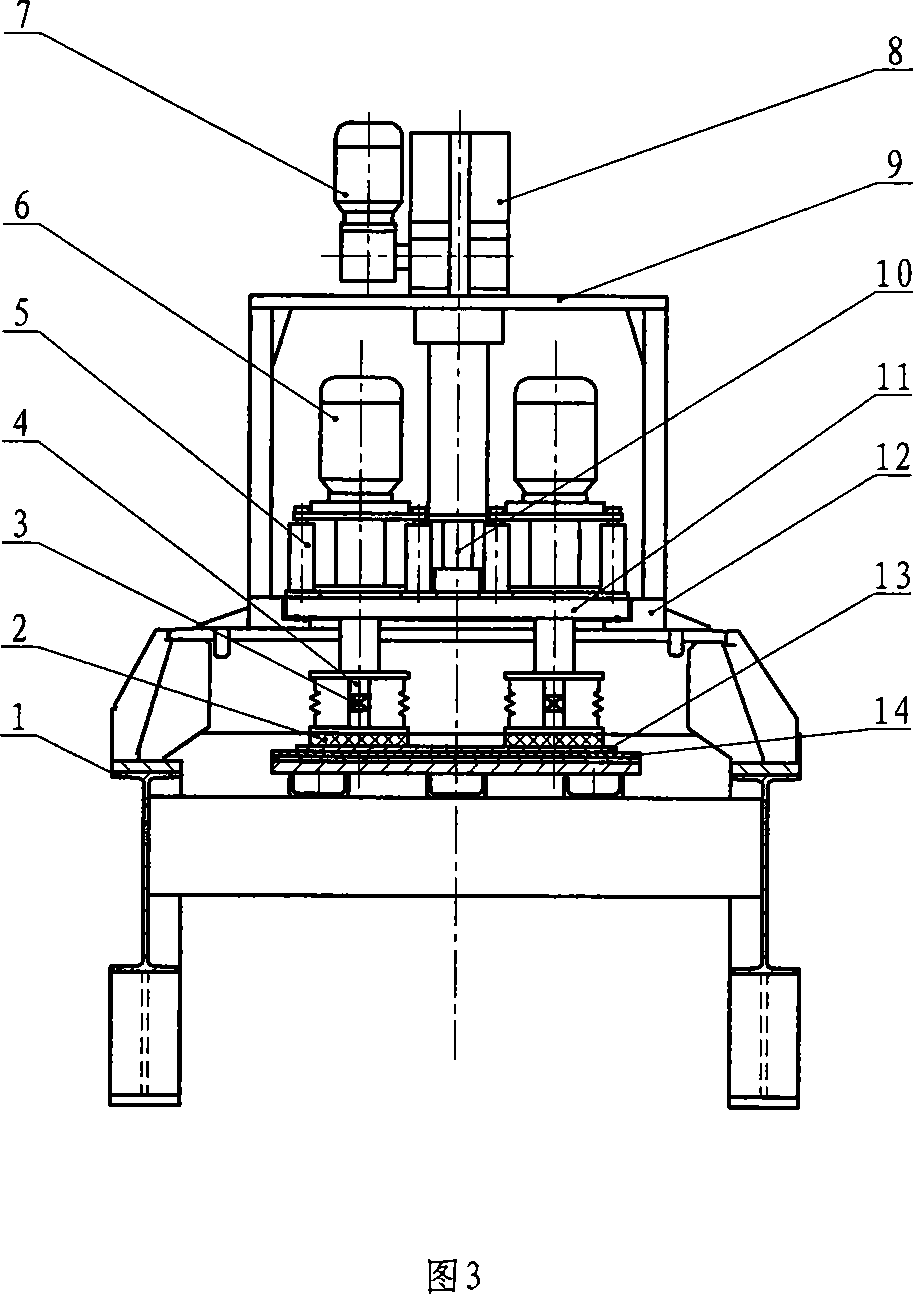

[0021] Referring to Figure 1, Figure 2, and Figure 3, a high-efficiency polishing machine is composed of a horizontal conveying system, a reciprocating swing system, a lifting type rotation mechanism, and a fixed revolution mechanism. The horizontal conveying system is composed of a frame 1, a conveyor belt 14, a main drive motor 15, a driving roller 16, a driven roller 19 and its supports. Movement, the workpiece 13 to be processed is placed on the conveyor belt 14. The reciprocating swing system is made up of swinging crossbeam 12, fixed support 17, swing motor 18, and swinging crossbeam 12 is supported on the fixed support 17, and swinging motor 18 drives swinging crossbeam 12 to do reciprocating swing. The lifting type self-rotating mechanism is composed of a grinding stone 2, a universal flexible coupling 3, a drive shaft 4, a cylinder 5 and a first motor 6. The first motor 6 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com