Wet water high-slipping resistance ink jet ceramic tile with delicate texture and making method thereof

A ceramic tile, anti-skid technology, applied in the field of ceramic tile production and manufacturing, can solve the problems of the static friction coefficient not meeting the requirements of anti-skid, difficult to clean, easy to hide dirt, etc., to achieve good decorative effect, bright color, excellent pollution resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

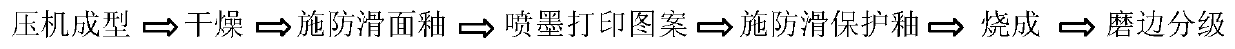

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0038] Step 2: Prepare anti-slip surface glaze according to the proportion: 50% potassium feldspar, 7% kaolin, 12% quartz, 11% calcined alumina, 5% nepheline, 7% zirconium silicate, 2% zinc oxide, 6% barium carbonate %. The chemical composition of the anti-skid glaze is: SiO 2 : 54.82%, Al 2 o 3 : 22.96%, Fe 2 o 3 : 0.2%, TiO 2 : 0.06%, CaO: 0.48%, MgO: 0.17%, K 2 O: 4.83%, Na 2 O: 2.74%, BaO: 4.65%, ZnO: 2%, ZrO 2 : 4.46%, loss on ignition: 2.83%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.80, and the amount of glaze is 500g / m 2 .

[0039] Step 3: Use an inkjet machine to inkjet print the pattern.

[0040] Step 4: Prepare anti-slip protective glaze according to the proportion: 48% potassium feldspar, 10% albite, 20% kaolin, 2% calcined alumina, 15% barium carbon...

Embodiment 2

[0046] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0047] Step 2: Prepare anti-slip surface glaze according to the ratio: 40% potassium feldspar, 10% albite feldspar, 10% kaolin, 8% quartz, 8% calcined alumina, 10% zirconium silicate, 10% barium carbonate, oxide Zinc 4%. The chemical composition of the anti-skid glaze is: SiO 2 : 51.40%, Al 2 o 3 : 19.60%, Fe 2 o 3 : 0.22%, TiO 2 : 0.06%, CaO: 0.25%, MgO: 0.17%, K 2 O: 3.84%, Na 2 O: 2.34%, BaO: 7.75%, ZnO: 3.99%, ZrO 2 : 6.37%, loss on ignition: 3.76%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.84, and the amount of glaze is 420g / m 2 .

[0048] Step 3: Use an inkjet machine to inkjet print the pattern.

[0049] Step 4: Prepare anti-slip protective glaze according to the proportion: 58% potassium feldspar, 10% kaolin, 5% quartz, 4% nepheline, 5% calcined alumina,...

Embodiment 3

[0054] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0055] Step 2: Prepare anti-slip surface glaze according to the proportion: potassium feldspar 45%, albite 5%, kaolin 8.5%, quartz: 10%, calcined alumina 9.5%, nepheline: 2.5%, zinc oxide 3%, silicon Zirconium acid 8.5%, barium carbonate 8%. The chemical composition of the anti-skid glaze is: SiO 2 : 53.04%, Al 2 o 3 : 21.28%, Fe 2 o 3 : 0.22%, TiO 2 : 0.06%, CaO: 0.39%, MgO: 0.17%, K 2 O: 4.33%, Na 2 O: 2.54%, BaO: 6.20%, ZnO: 2.99%, ZrO 2 : 5.42%, loss on ignition: 3.36%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.82, and the amount of glaze is 460g / m 2 .

[0056] Step 3: Use an inkjet machine to inkjet print the pattern.

[0057] Step 4: Prepare anti-skid protective glaze according to the ratio: potassium feldspar 53%, albite 5%: kaolin 15%, quartz: 2.5%, neph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com