Super wear-resistant rubber foamed sport shoe material and preparation method thereof

A rubber foaming and super wear-resistant technology, which is applied to footwear, footwear, soles, etc., can solve the problems of poor wear resistance and low anti-slip performance, and achieve good anti-slip performance, excellent wear resistance and anti-slip properties. The effect of slippery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

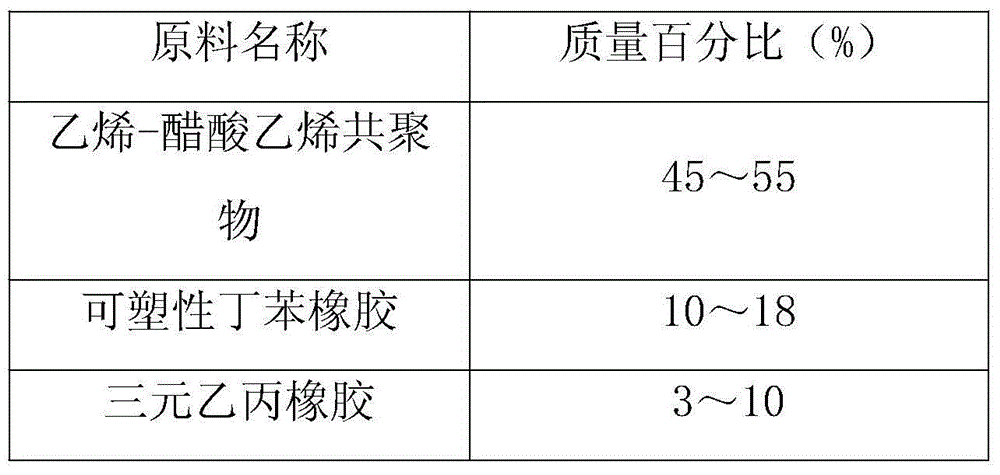

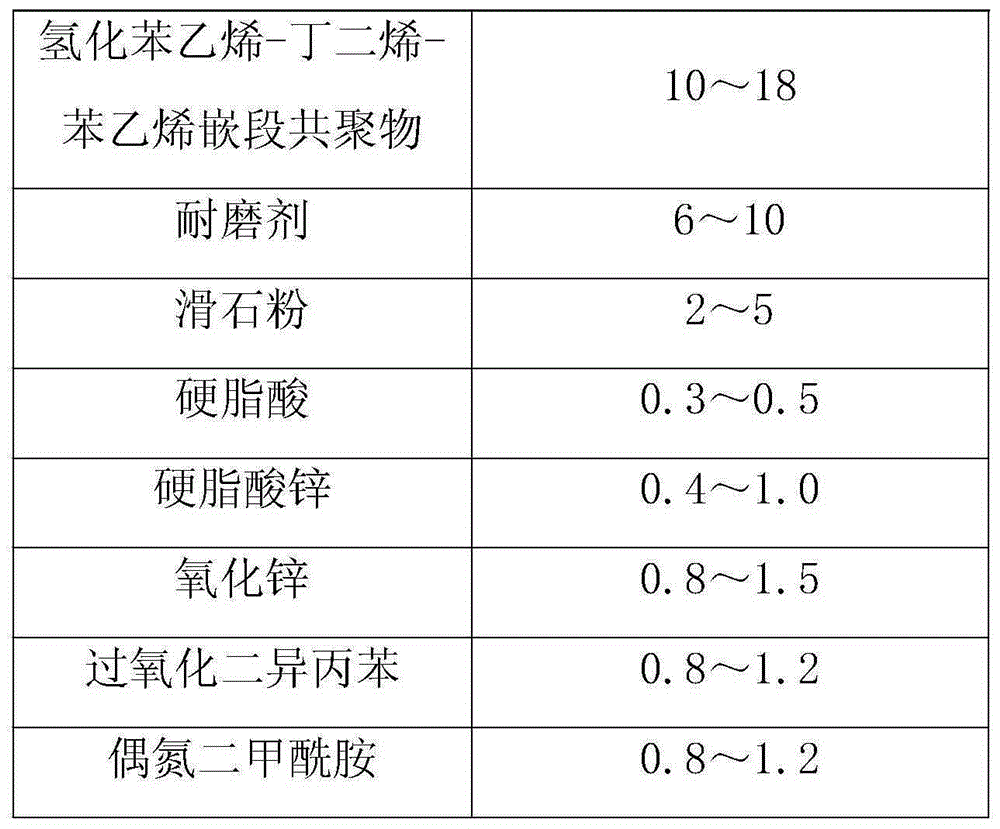

Method used

Image

Examples

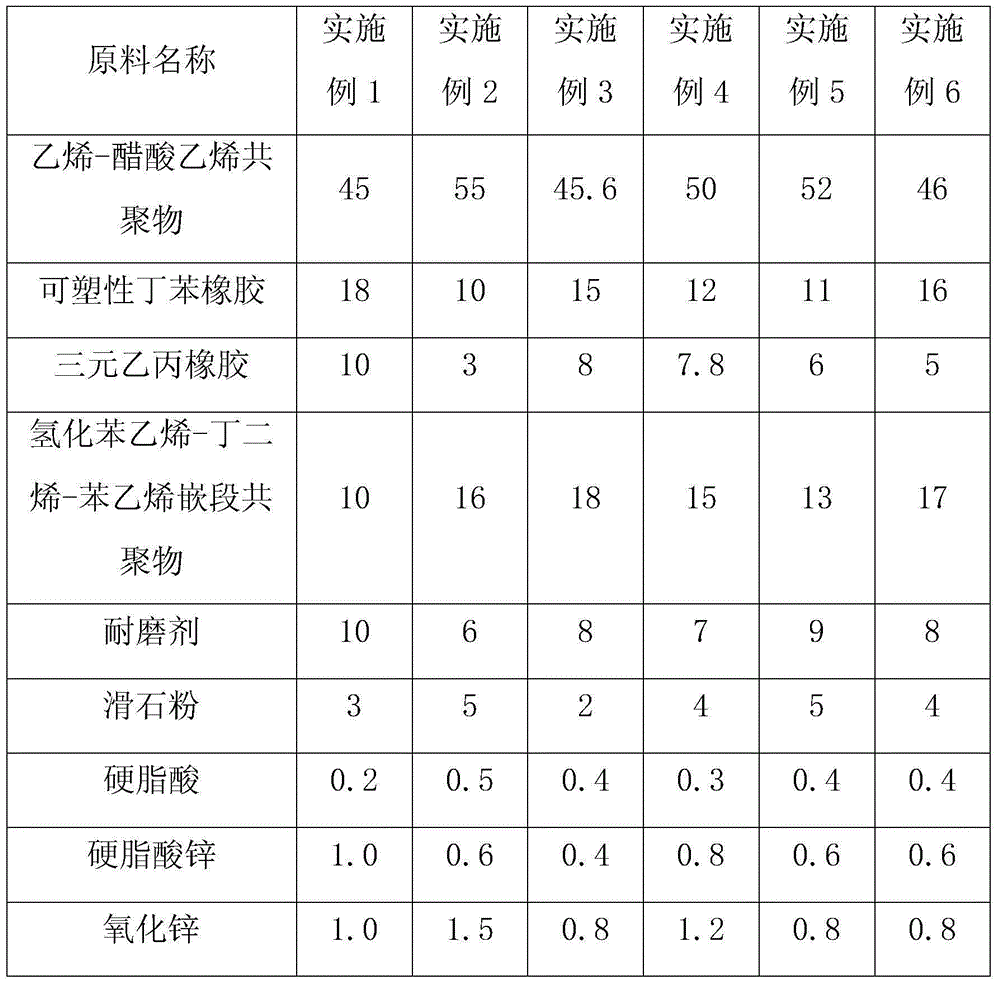

Embodiment Construction

[0024] For a better understanding of the present invention, the present invention will be further specifically described below through the following examples, but it should not be construed as a limitation of the present invention. For some non-essential improvements and adjustments made by those skilled in the art according to the above-mentioned content of the invention, It is also considered to fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com