Ecological permeable pavement brick and preparation method thereof

A permeable pavement brick and ecological technology, applied in the field of construction, can solve the problems of uneven mixing of mortar and brick, low average strength, poor wear resistance, etc., to reduce production costs, high flexural strength and split tensile strength, Good slip resistance and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

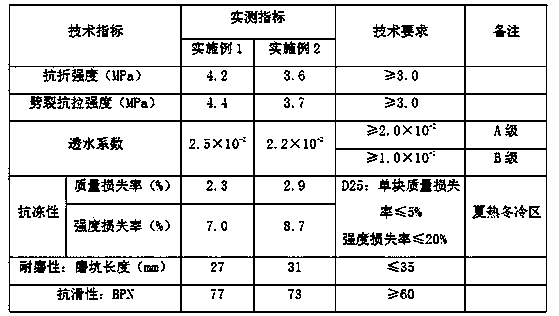

Examples

Embodiment 1

[0020] An ecological permeable pavement brick, made of the following raw materials in parts by weight: cement: fly ash: building slag coarse aggregate: steel slag coarse aggregate: sand: water: water reducer = 1:0.25:1.60:1.70: 0.9:0.50:0.031.

[0021] In this embodiment, the cement is ordinary Portland cement with a strength grade of 42.5R; the fly ash is Class I fly ash of Zouping Power Plant; the water absorption rate of the building slag coarse aggregate is 15%, the apparent density is 2.35g / cm 3 , the particle size is 5-10mm; the steel slag coarse aggregate has a water absorption rate of 2.0% and an apparent density of 3.5g / cm 3 , the particle size is 10-15mm; the sand is natural river sand with a fineness modulus of 2.8. ; The water reducer is a polycarboxylate water reducer.

[0022] According to the preparation method of the ecological permeable pavement brick described in the present embodiment 1, comprises the following steps:

[0023] a. Use mechanical mixing, f...

Embodiment 2

[0026] An ecological permeable pavement brick is made of the following raw materials in parts by weight: cement: fly ash: building slag coarse aggregate: steel slag coarse aggregate: sand: water: water reducer =1:0.30:1.8:1.7:0.7:0.52:0.038.

[0027] Described cement is the composite portland cement that strength grade is 32.5R; Described fly ash is Jinan Huangtai Power Plant II class fly ash; The apparent density is 2.30g / cm 3 , the particle size is 5-10mm. The steel slag coarse aggregate has a water absorption rate of 2.5%, an apparent density of 3.4g / cm3, and a particle size of 10-15mm; the described sand is natural river sand with a fineness modulus of 2.9; the described water reducing The agent is a naphthalene-based water reducer.

[0028] The preparation method of described ecological permeable pavement brick, comprises the following steps:

[0029] a. Use mechanical mixing, first add sand to the concrete mixer, then add cement and fly ash, dry mix for 1-2 minutes u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com