Skid resistant composite structure of miniature pile and method for reinforcing side slope

A combined structure and micro-pile technology, which is applied in the direction of foundation structure engineering, excavation, and sheet pile walls, etc., can solve the problem of high cost of support and reinforcement structures, and achieve the effect of simple construction, low investment, and reinforcement of rock and soil slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

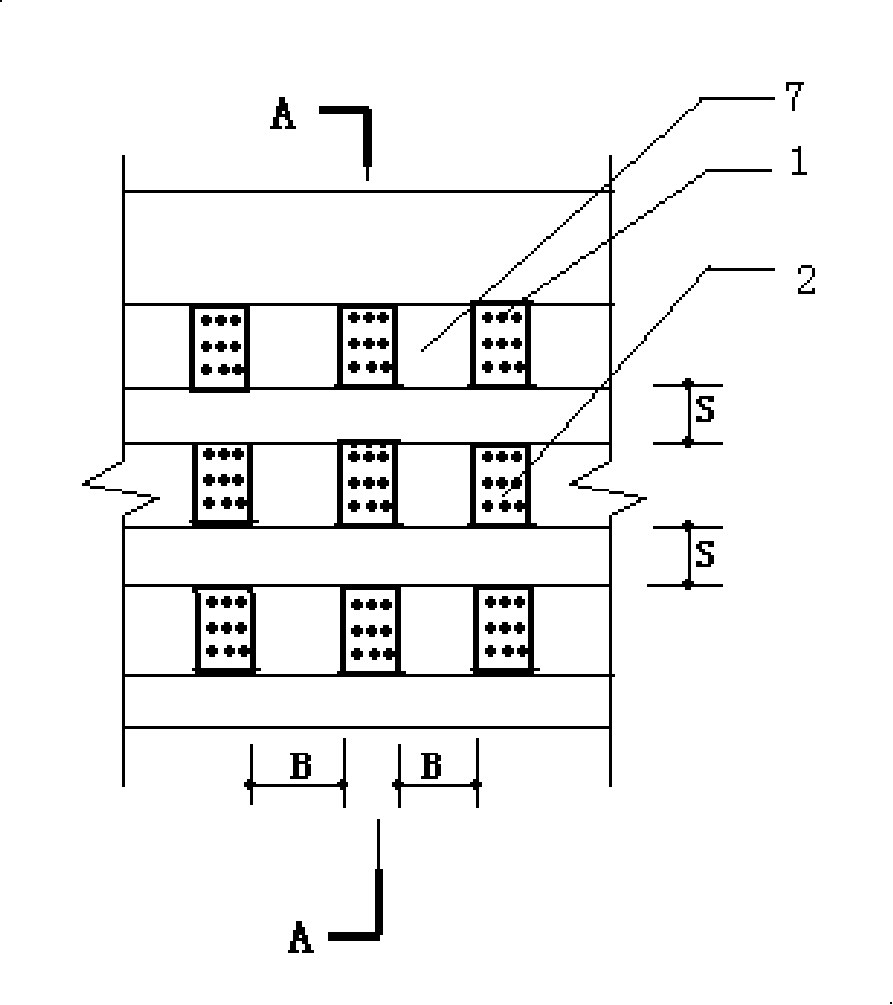

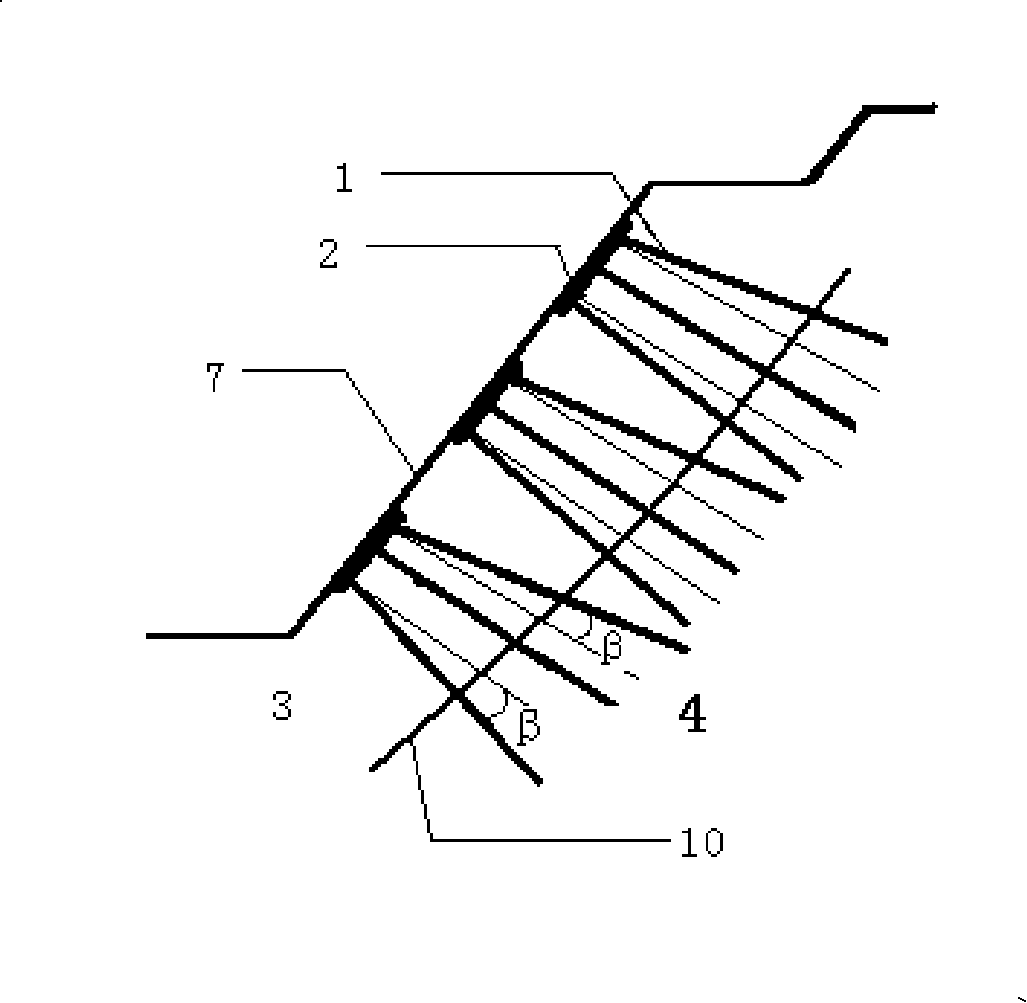

[0042] refer to figure 1 and figure 2 , the micropile anti-sliding combination structure of the present invention is arranged at 7 places on the slope surface, and it includes a plurality of top plates 2 arranged on the slope surface according to a certain row spacing S and spacing B, and the micro piles 1 fixed on each top plate 2 pass through The sliding body 3 and the sliding surface 10 are anchored in the bedrock 4 . Through the pile group effect formed by the anti-sliding micro piles arranged in rows and columns, the shear strength of the rock mass is improved, so that the entire unstable rock and soil mass becomes a whole without slipping.

Embodiment 2

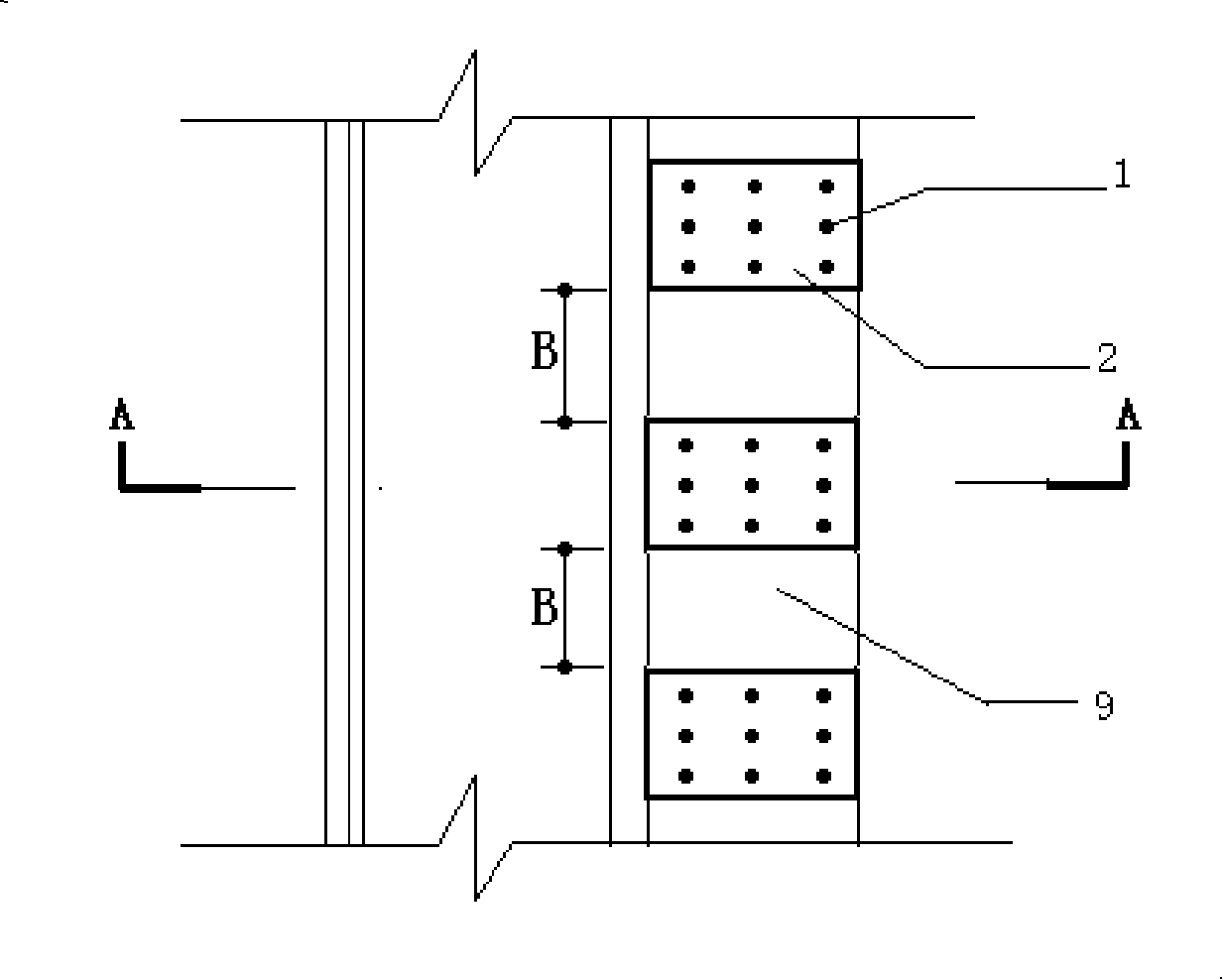

[0044] refer to image 3 , Figure 4 and Figure 5 , Figure 6 , the micro pile anti-sliding composite pile structure of the present invention is arranged at the toe platform 9 and the mid-slope platform 8, and it includes a plurality of top plates 2 arranged at a certain interval B at the toe platform 9 and the mid-slope platform 8, The micro-pile 1 fixed on each top plate 2 passes through the sliding body 3 and the sliding surface 10 and is anchored in the bedrock 4 . The pile group effect formed by the micro-pile anti-sliding composite structure arranged in rows and columns improves the shear strength of the rock mass, making the entire unstable rock and soil mass a whole without slipping.

[0045] On-site construction can usually be carried out in the following steps:

[0046] (1) construction preparation, prepare steel member 6;

[0047] (2) Level the slope or platform surface, arrange points, and drill holes;

[0048] (3) Drill the anchor hole to the design depth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com