Silicone Gloves

a technology of silicone gloves and silicone sheets, applied in the field of silicone gloves, can solve the problems of inconvenience for users, inability to project the effect of existing gloves, and inability to be done, and achieve the effect of high resistance to heat and moisture, and high resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0095]Example 1 is an embodiment of the silicone compositions disclosed herein. Example 1 was prepared by mixing or milling a mixture of 24.25 wt. % of ZY7821, 24.25 wt. % of QT910U, and 48.5 wt. % of ZY7817 (all of the three ingredients are silicone rubbers; obtained from Shin-Etsu Chemical Co., Ltd., Tokyo, Japan); 1.5 wt. % of SKH-158B (a cross-linking agent; obtained from Shin-Etsu Chemical Co., Ltd., Tokyo, Japan); and 1.5 wt. % of SA924, SB330, and SB400 (all are colorants and were obtained from Holland Colours NV, Apeldoorn, the Netherlands). All the wt. % amounts are based on the total weight of Example 1.

example 2

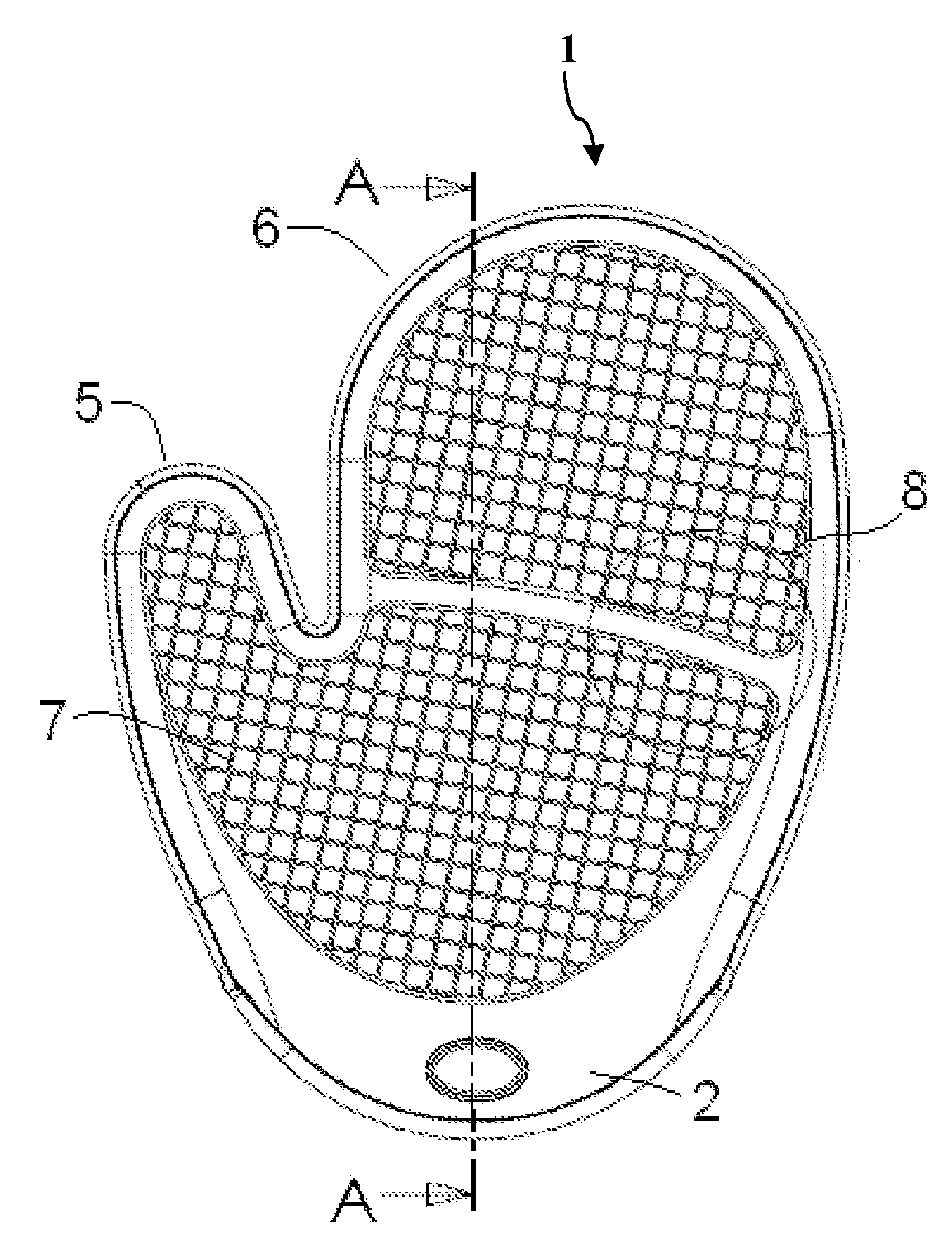

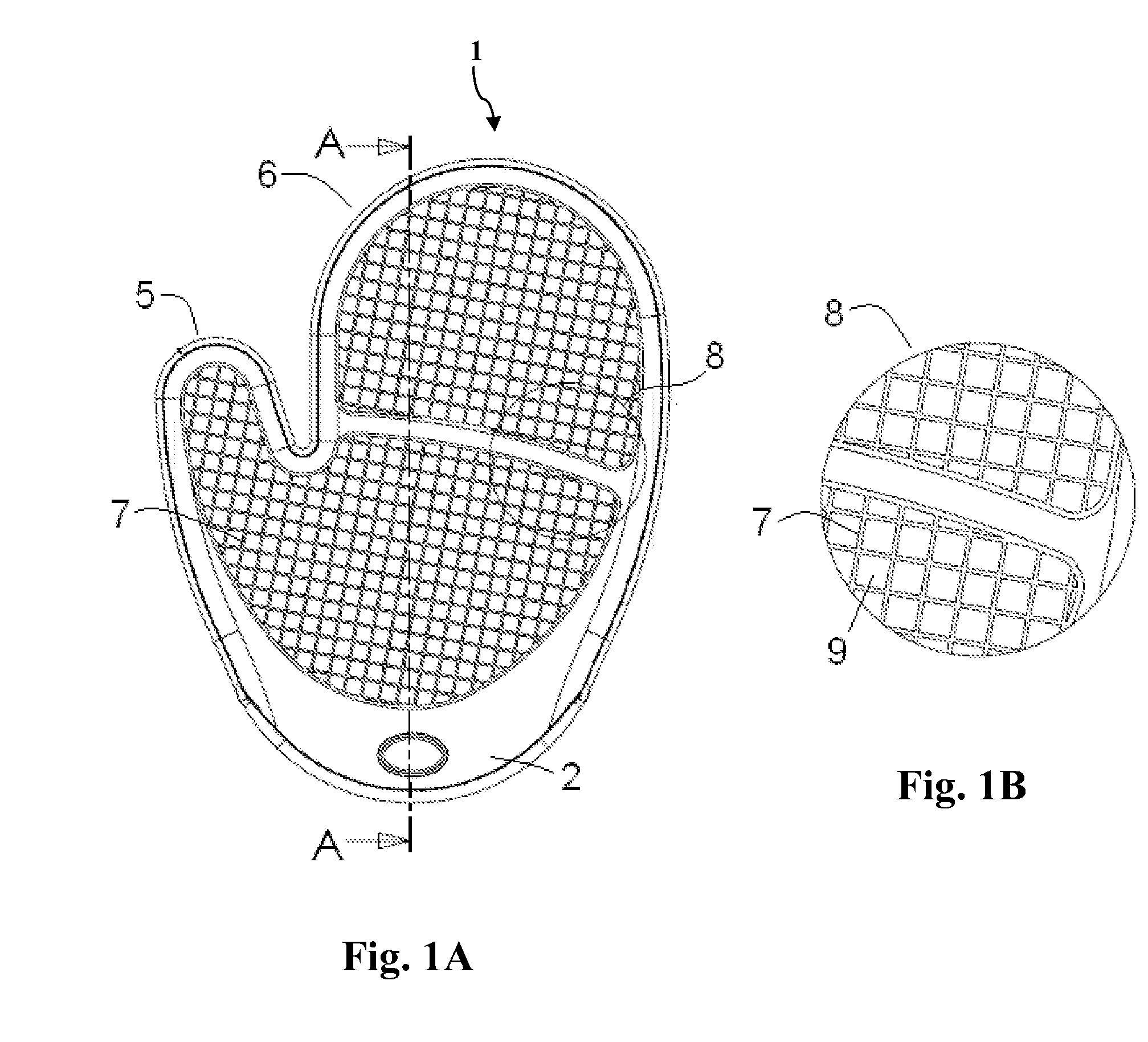

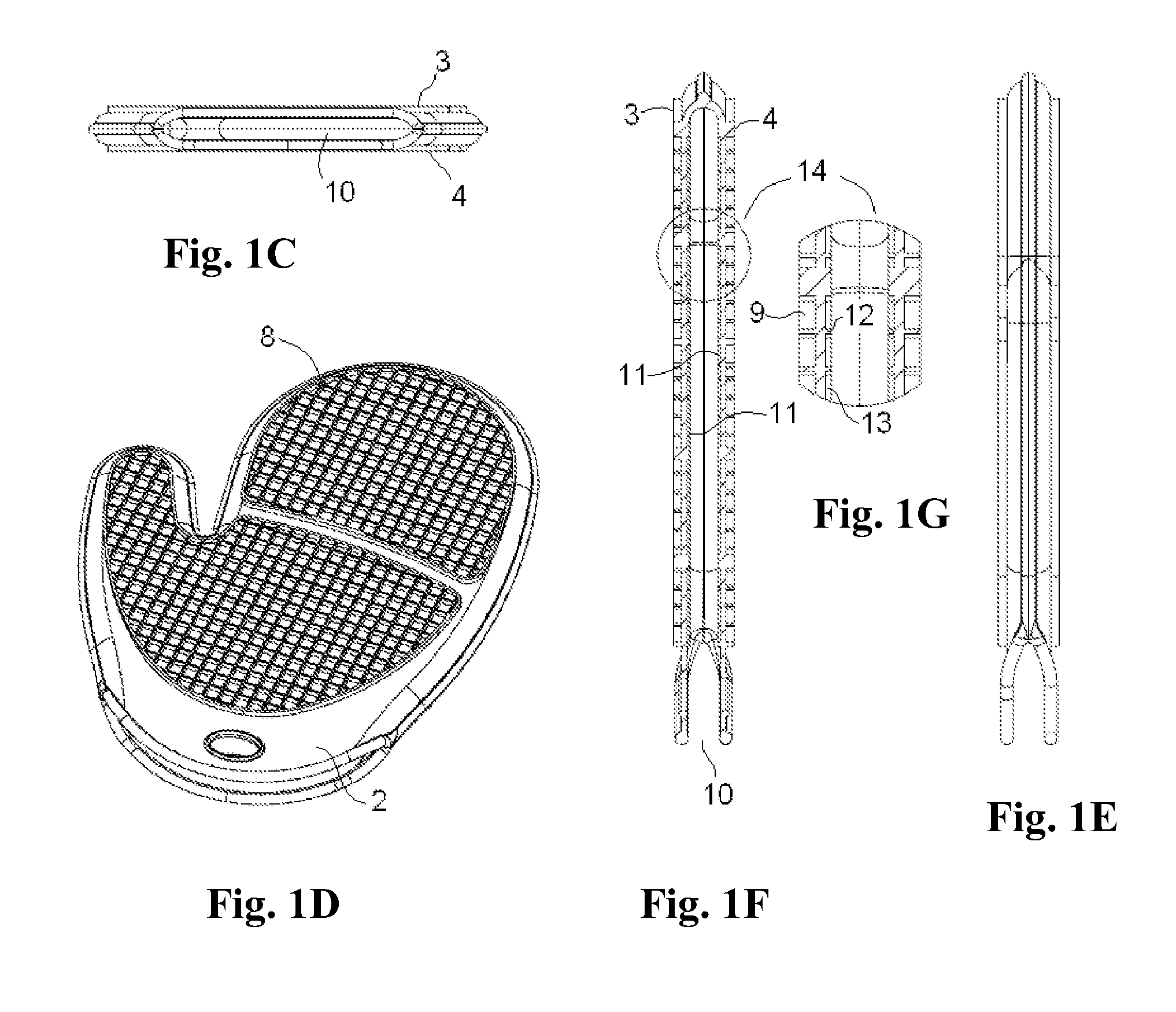

[0096]Example 2 is an embodiment of the silicone gloves disclosed herein. Example 1 was made into a flat sheet with a thickness of about 2 mm for use in Example 2. Four glove-shaped pieces of an identical glove shape were carved out from the flat sheet, each of which weighed about 55 g. A glass-fiber sheet corresponding to the shape of the glove piece with a size slightly smaller than the glove piece was placed on top of one glove piece. Then, another glove piece was placed on top of the glass-fiber sheet, producing a first layer of the glove. Then, the same steps were repeated to produce a second layer of the glove. The molding machine is commercially available from X. L. B. Rubber Machinery Corporation, Guangzhou, Model No. XLS-1. The mold had 2 tooling cavities and each comprised an upper portion, a lower portion and a mandrel between the upper portion and the lower portion. The first layer of the glove was placed on the upper side of the mandrel; the second layer of the glove wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com