Tread rubber composition of all-steel truck snow tire

A rubber composition, truck technology, applied in special tires, tire parts, vehicle parts, etc., can solve the problems of damaged road pavement, long snow season, heavy snowfall, etc., and achieve high snow index and tread hardness Moderate, good snow grip and adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of all-steel truck snow tire tread rubber composition, formula is as follows (in parts by weight):

[0014] 50 parts of natural rubber, 27.5 parts of oil-extended neodymium-based butadiene rubber, 30 parts of solution polystyrene butadiene rubber, 28 parts of highly dispersed white carbon black, 42 parts of carbon black N22042, 2.8 parts of coupling agent liquid Si69, 4 parts of aromatic oil, 5 parts of zinc oxide, 1.5 parts of stearic acid, 2.8 parts of anti-aging agent 6PPD, 1.8 parts of anti-aging agent RD, 3 parts of microcrystalline wax, 1.7 parts of oil-extended sulfur, 0.9 parts of accelerator NS, and 0.4 parts of accelerator DPG , anti-scorch agent CTP0.18 parts.

[0015] The above formula is mixed step by step in an internal mixer according to a certain process to obtain the required rubber compound.

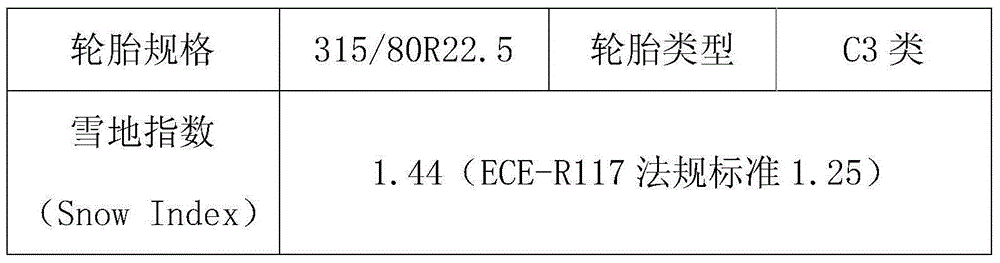

[0016] The main technical index of the tread rubber composition that uses embodiment 1 to make is as follows:

[0017] project

unit

...

Embodiment 2

[0023] A kind of all-steel truck snow tire tread rubber composition, formula is as follows (in parts by weight):

[0024] 50 parts of natural rubber, 27.5 parts of oil-extended neodymium-based butadiene rubber, 30 parts of solution-polymerized styrene-butadiene rubber, 23 parts of highly dispersed white carbon black, 48 parts of carbon black N22048, 2.3 parts of coupling agent liquid Si69, 7 parts of aromatic oil, 5 parts of zinc oxide, 1.5 parts of stearic acid, 2.8 parts of anti-aging agent 6PPD, 1.8 parts of anti-aging agent RD, 3 parts of microcrystalline wax, 1.7 parts of oil-extended sulfur, 0.9 parts of accelerator NS, 0.25 parts of accelerator DPG , anti-scorch agent CTP0.18 parts. Example 3

Embodiment 3

[0025] A kind of all-steel truck snow tire tread rubber composition, formula is as follows (in parts by weight):

[0026] 42 parts of natural rubber, 34.4 parts of oil-extended neodymium-based butadiene rubber, 33 parts of solution polystyrene butadiene rubber, 25 parts of highly dispersed white carbon black, 52 parts of carbon black N22052, 2.8 parts of coupling agent liquid Si69, 4 parts of aromatic oil, 5 parts of zinc oxide, 1.5 parts of stearic acid, 2.8 parts of anti-aging agent 6PPD, 1.8 parts of anti-aging agent RD, 3 parts of microcrystalline wax, 1.7 parts of oil-extended sulfur, 0.9 parts of accelerator NS, 0.25 parts of accelerator DPG , anti-scorch agent CTP0.18 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com