Dry-granular glazed ceramic tile and preparation method thereof

A dry granule glaze and ceramic tile technology, applied in the field of ceramic tile preparation, can solve the problems of cumbersome preparation methods, pollution, high consumption of materials and energy, etc., and achieve the goals of easy consumption of materials and energy, reduction of pollution, and control of consumption of materials and energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

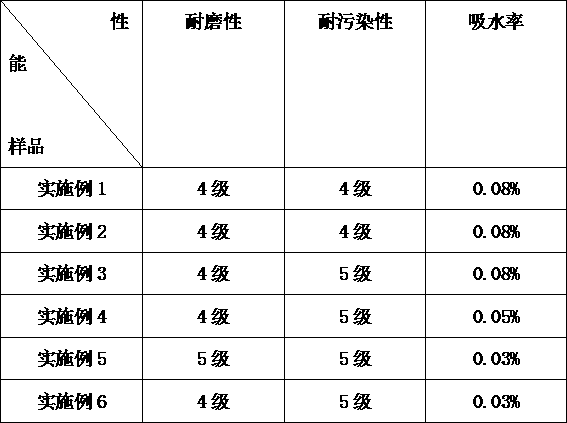

Examples

Embodiment 1

[0020] A dry-grained glaze ceramic tile, which includes a ceramic body, on which a surface glaze and a dry-grained glaze are sequentially applied.

[0021] A method for preparing dry glaze tiles, the preparation steps of which are as follows: (1) spray water on the dried ceramic body to a wet state with a surface water content of 5-10%, and then apply the surface glaze; (2) The dry glaze is printed on the glazed ceramic body with a rubber roller engraved with granular patterns; (3) After being calcined in a kiln for 1 hour, the dry glaze tiles are obtained, and the calcination temperature is 1190°C.

[0022] The ceramic body adopts a general ceramic glaze body, and the surface glaze can be realized by using a bell jar type glazer in the prior art.

[0023] The surface glaze is prepared from the following raw materials in parts by weight: 8 parts of milky white frit glaze, 35 parts of feldspar, 5 parts of calcite, 10 parts of spodumene, 7 parts of washed kaolin, 8 parts of calc...

Embodiment 2

[0026] A kind of preparation method of dry glaze ceramic tile, its preparation steps are as follows:

[0027] (1) Spray water on the dried ceramic body to a wet state with a surface water content of 5-10%, and then apply the surface glaze; (2) Use a rubber roller engraved with granular patterns to print the dry granular glaze on the On the glazed ceramic body; (3) After calcination in a kiln for 1 hour, the dry glaze tiles are obtained, and the calcination temperature is 1190°C.

[0028] The ceramic body adopts a general ceramic glaze body, and the surface glaze can be realized by using a bell jar type glazer in the prior art.

[0029] The surface glaze is prepared from the following raw materials in parts by weight: the surface glaze is prepared from the following raw materials in parts by weight: 15 parts of opalescent frit glaze, 38 parts of feldspar, 18 parts of calcite, and 13 parts of spodumene 7 parts of washed kaolin, 12 parts of calcined kaolin, 12 parts of aluminum ...

Embodiment 3

[0032] A kind of preparation method of dry glaze ceramic tile, its preparation steps are as follows:

[0033] (1) Spray water on the dried ceramic body to a wet state with a surface water content of 5-10%, and then apply the surface glaze; (2) Use a rubber roller engraved with granular patterns to print the dry granular glaze on the On the glazed ceramic body; (3) After calcination in a kiln for 1 hour, the dry glaze tiles are obtained, and the calcination temperature is 1190°C.

[0034] The ceramic body adopts a general ceramic glaze body, and the surface glaze can be realized by using a bell jar type glazer in the prior art.

[0035] The surface glaze is prepared from the following raw materials in parts by weight: 12 parts of frit, 36 parts of feldspar, 15 parts of calcite, 12 parts of spodumene, 7 parts of washed kaolin, 10 parts of calcined clay, 11 parts of alumina, 6 parts of barium carbonate, 2 parts of zinc oxide, 7 parts of zirconium silicate, 1.5 parts of sodium tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com