Preparation method of thin layer graphene polymer composite material

A thin-layer graphene and composite material technology, applied in the field of nanomaterials, can solve the problems of complex preparation process, difficult cycle life, comparison of activated carbon, etc., and achieve the effects of simple preparation process, environmental friendliness and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Further speaking, the preparation method of this thin-layer graphene polymer composite material may comprise the following steps:

[0027] The preparation method of this thin-layer graphene polymer composite material comprises the following steps:

[0028] Provide graphite intercalation compounds;

[0029] Using graphite intercalation compounds to catalyze the reaction with peroxides to prepare thin-layer graphene adsorbed with catalysts;

[0030] Or use the graphite intercalation compound and peroxide catalytic reaction, after purification, the prepared thin-layer graphene, and additionally support the catalyst on the thin-layer graphene, and prepare the thin-layer graphene adsorbed with the catalyst;

[0031] Add polymer monomers to graphite intercalation compounds or thin-layer graphene adsorbed with catalysts to form a mixed reaction system, catalyze polymerization reactions at different temperatures, purify, wash, and dry to obtain composite materials aft...

Embodiment 1

[0045] Example 1 The preparation method of this thin-layer graphene polymer composite material is:

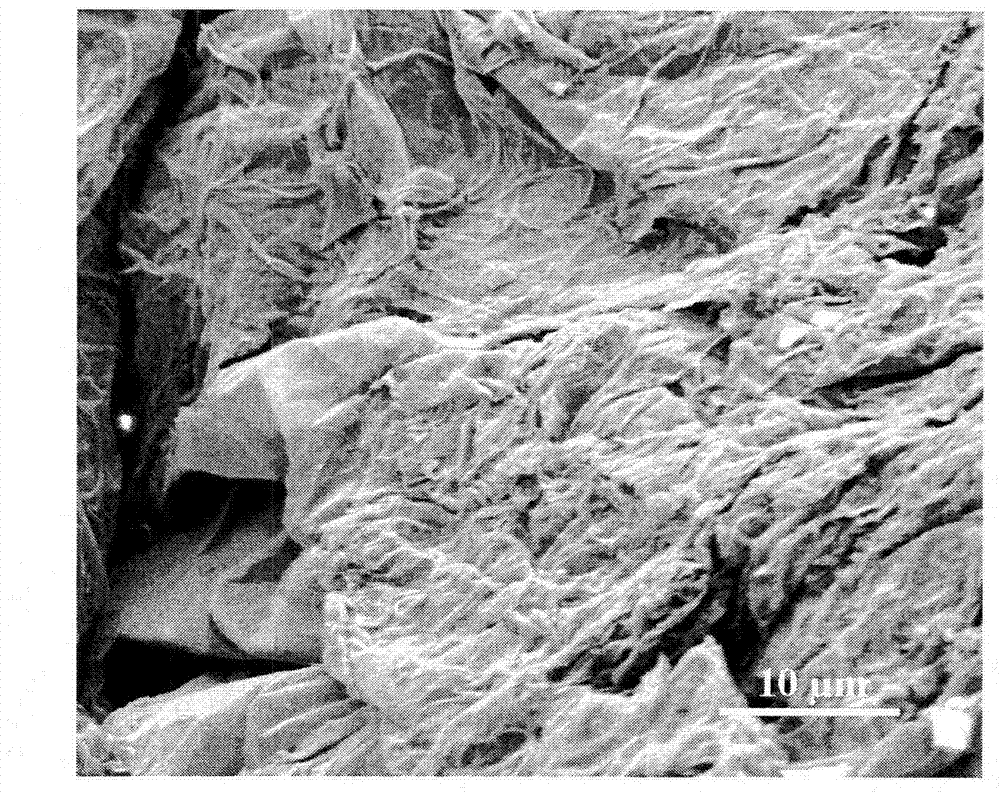

[0046]Graphite sheets are intercalated with concentrated sulfuric acid or metal salts, treated with hydrochloric acid, hydrogen peroxide, water, etc., and finally purified to obtain thin-layer graphene with catalysts adsorbed. React in the kettle at 280°C for 72 h, then soak in 30% hydrogen peroxide at room temperature for 24 h, add 0.5 ml of aniline, 0.5 ml of pyrrole, and 0.5 ml of thiophene to the aqueous solution mixture of 1 g of the product, react at 25°C for 12 h, wash with dilute hydrochloric acid Wash 5 times with aqueous solution, 100 ml each time, wash 5 times with ethanol, 100 ml each time, and then vacuum-dry the product, its form is as follows figure 1 Therefore, the lateral size of graphene is greater than 100 μm, and the polymer is uniformly distributed on the surface of graphene.

Embodiment 2

[0047] Example 2 The preparation method of this thin-layer graphene polymer composite material is:

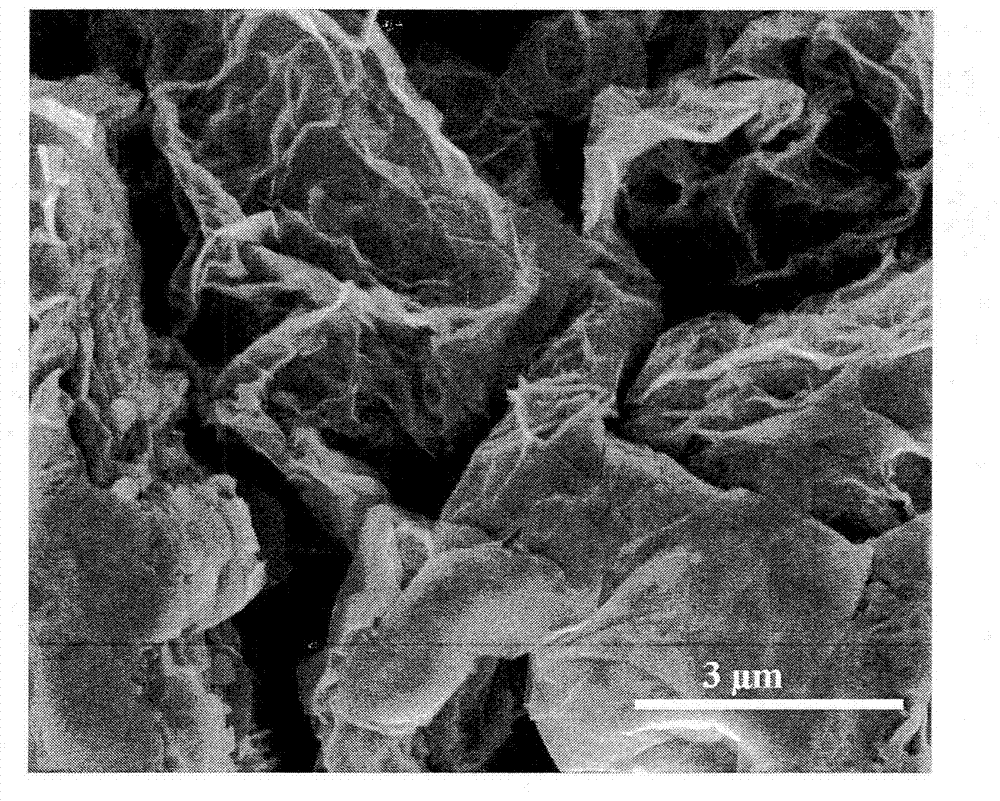

[0048] 5 g of graphite flakes of 325 mesh and 15 g of ferric chloride were added to an autoclave at 350 °C for 72 h, and then soaked in 30% hydrogen peroxide at room temperature for 24 h, and 1 g of the product was taken from the aqueous solution mixture, and 1 ml of aniline was added to it, 1 ml pyrrole, 1 ml thiophene, react at 50°C for 24 h, wash 10 times with dilute hydrochloric acid aqueous solution, wash 5 times with ethanol each time, 100 ml each time, and then vacuum-dry the product, its form is as follows figure 2 shown. The lateral size of graphene is greater than 100 μm, and the layers have been clearly separated, indicating that the graphene has been cleaved, and the polymers are distributed on the graphene surface in blocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com