Flame-retardant PET (polyethylene terephthalate)/nanocarbon microsphere composite material and preparation method thereof

A technology of nano-carbon microspheres and composite materials, which is applied in the field of preparation of flame-retardant PET/nano-carbon microsphere composite materials, which can solve the problems of poor compatibility of polymer materials and low combustion performance, and achieve improved flame-retardant properties , maintain mechanical properties, improve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

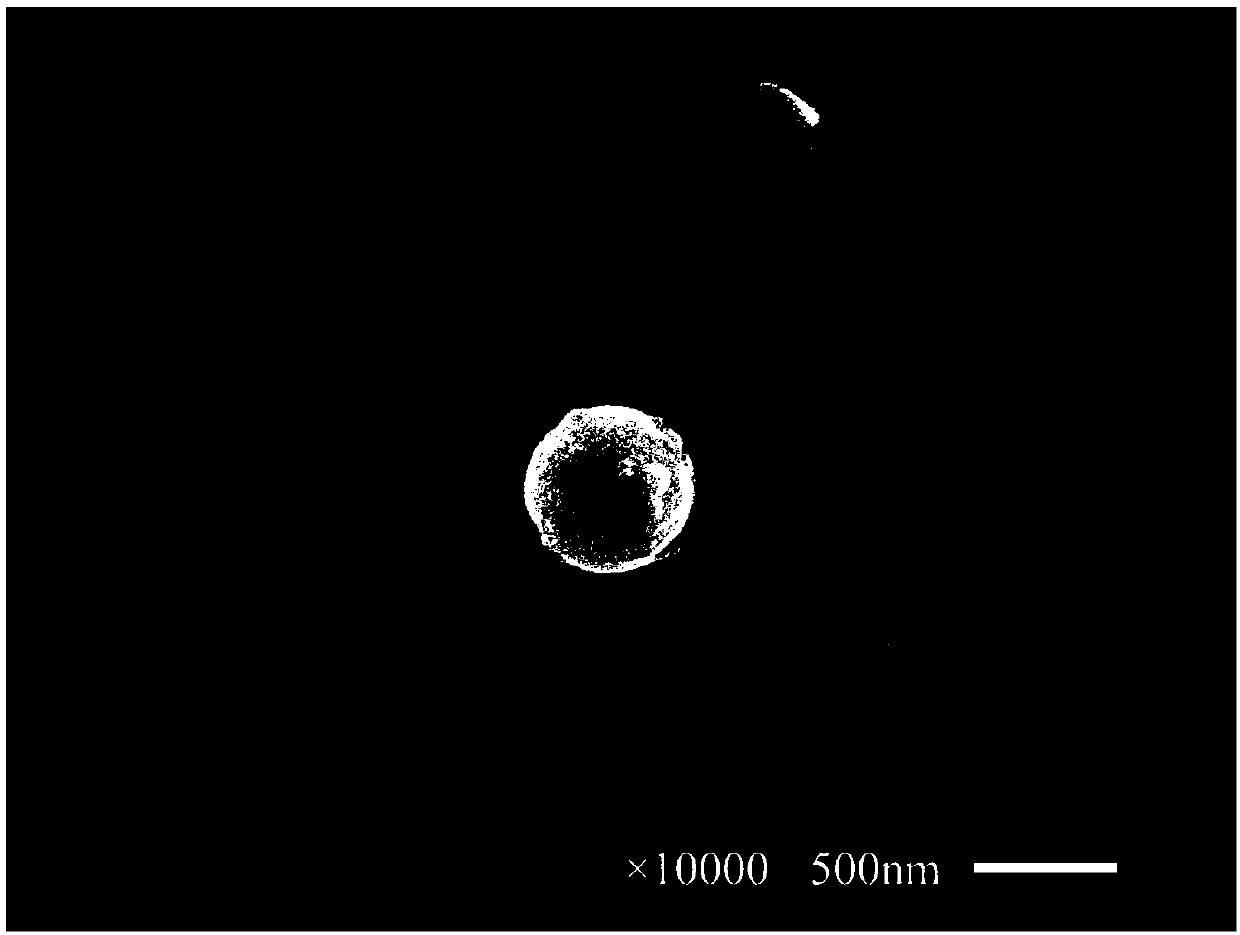

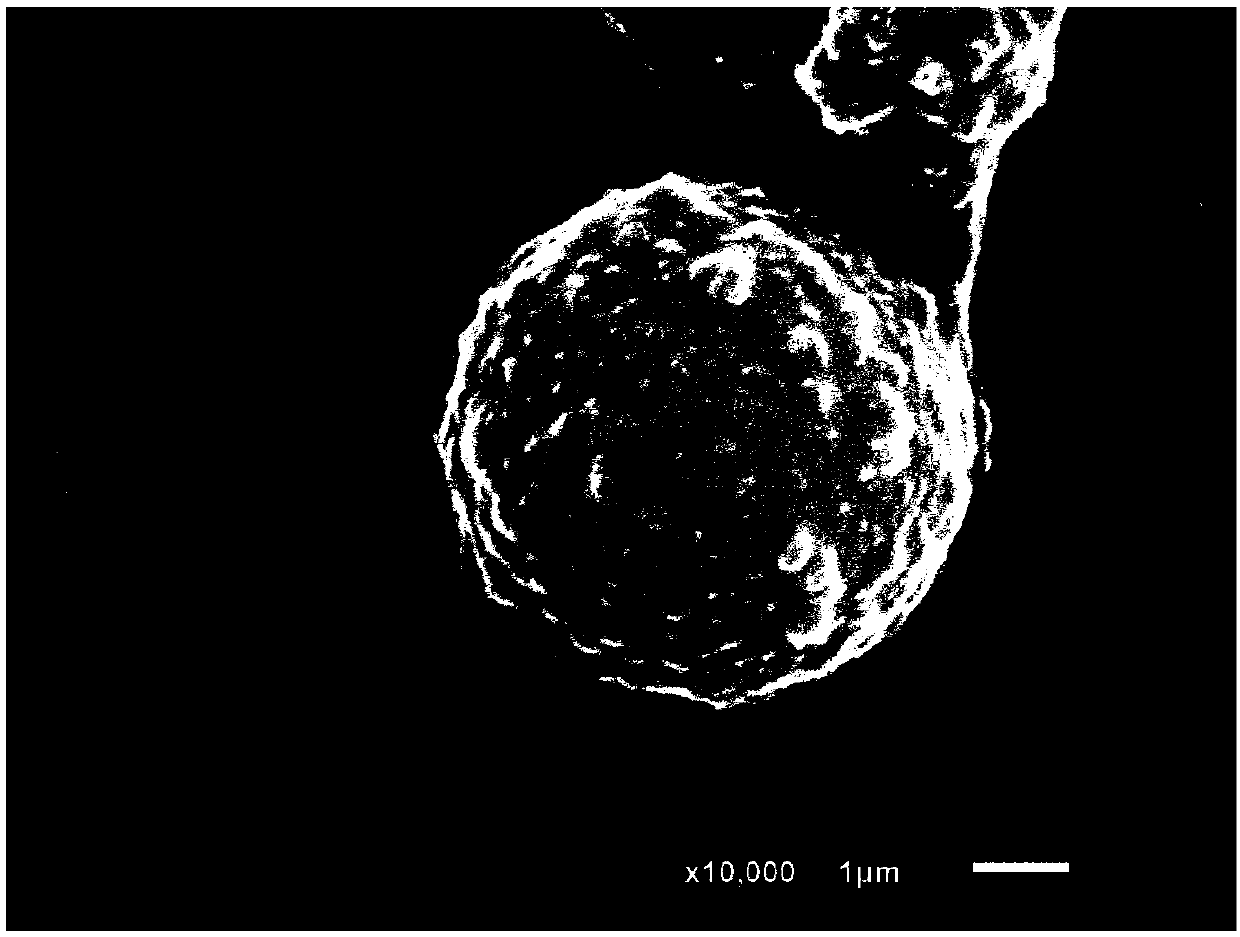

[0041] Add 0.5mol / L cyclodextrin solution into the Erlenmeyer flask, then heat it in a water bath until it is completely dissolved, quickly add it to the hydrothermal synthesis kettle, and react at 160°C for 10h. After the reaction is completed, put the carbon microspheres into put into a centrifuge tube, wash with ethanol, and disperse in an ultrasonic disperser, then place the dispersed carbon microspheres in an ultracentrifuge for centrifugation, repeat the above washing, disperse, and finally place them in a constant temperature drying oven at 80°C to dry overnight . Carbon microspheres with a smaller average particle size were prepared, and the average particle size was 420nm.

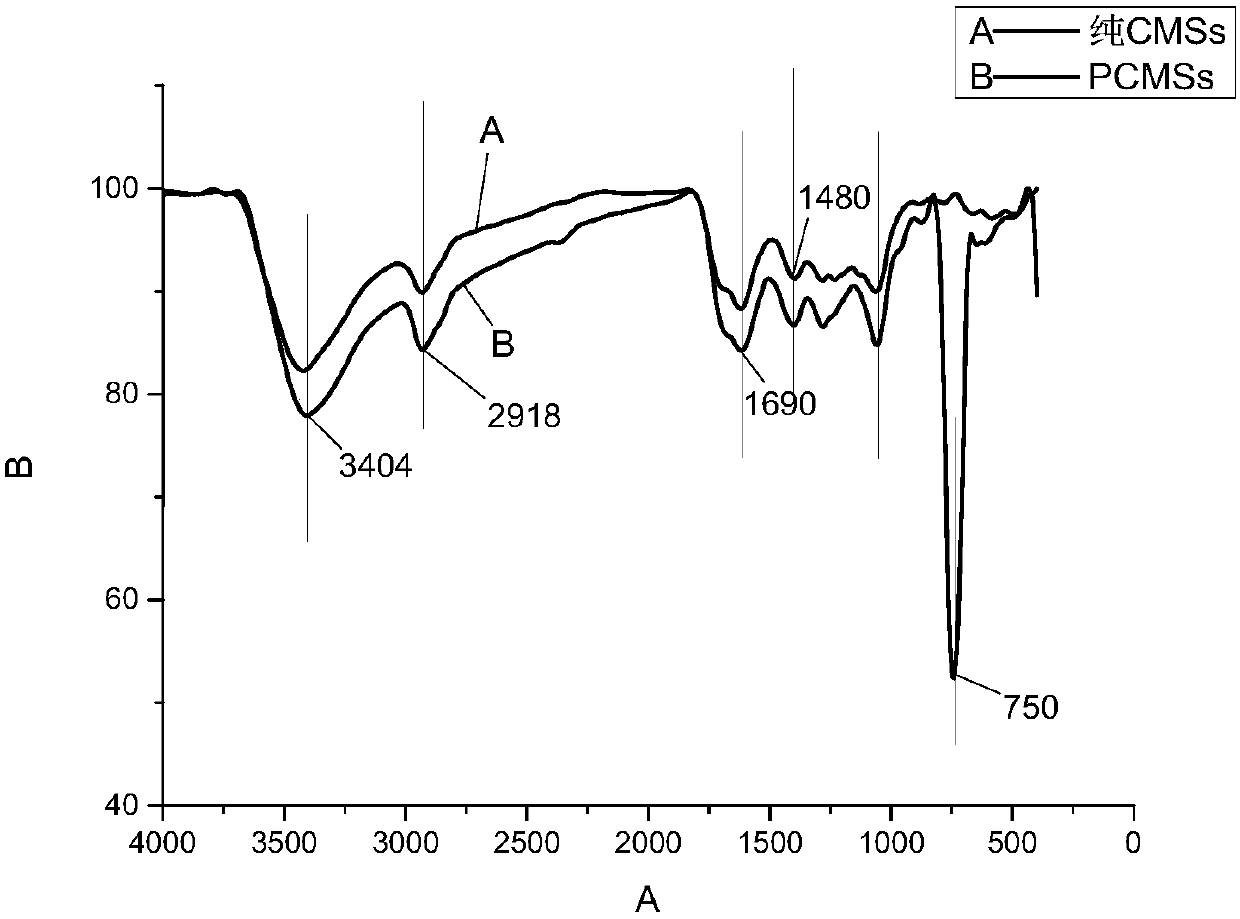

[0042] Then use a 250W low-temperature plasma device to discharge for 5 minutes to generate hydroxyl and carboxyl groups on the surface of the carbon microspheres;

[0043] React guanidine carbonate and concentrated phosphoric acid with a molar ratio of 1:1-1.25 at 65°C for 2 hours to obtain guan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com