Method and device for judging quality of mixed color points of recycled plastic

A technology for recycled plastics and quality judgment, applied in image analysis, image enhancement, instruments, etc., can solve the problems of low recognition accuracy of large-sized variegated dots and difficulty in identifying small-sized variegated dots, etc. Fast speed and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

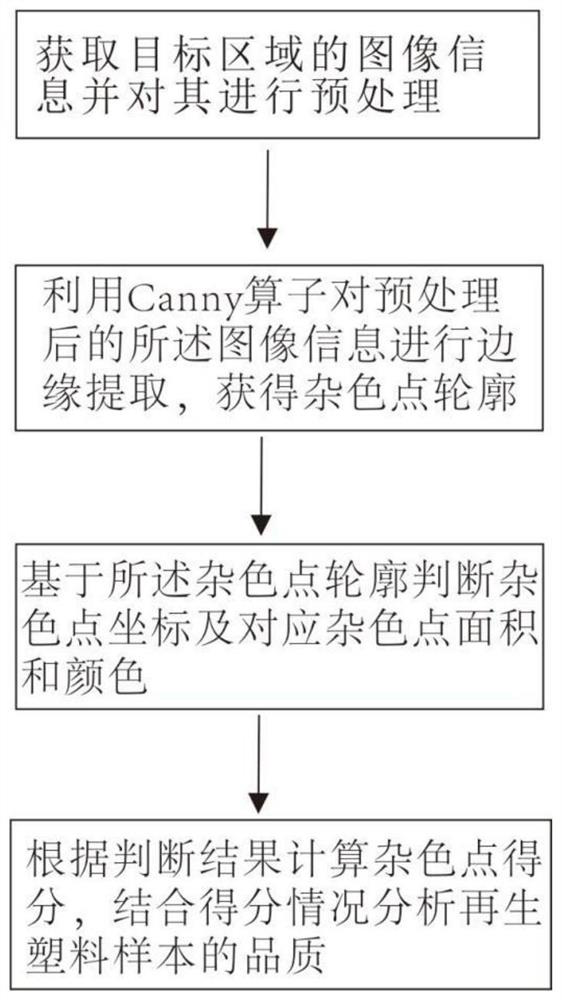

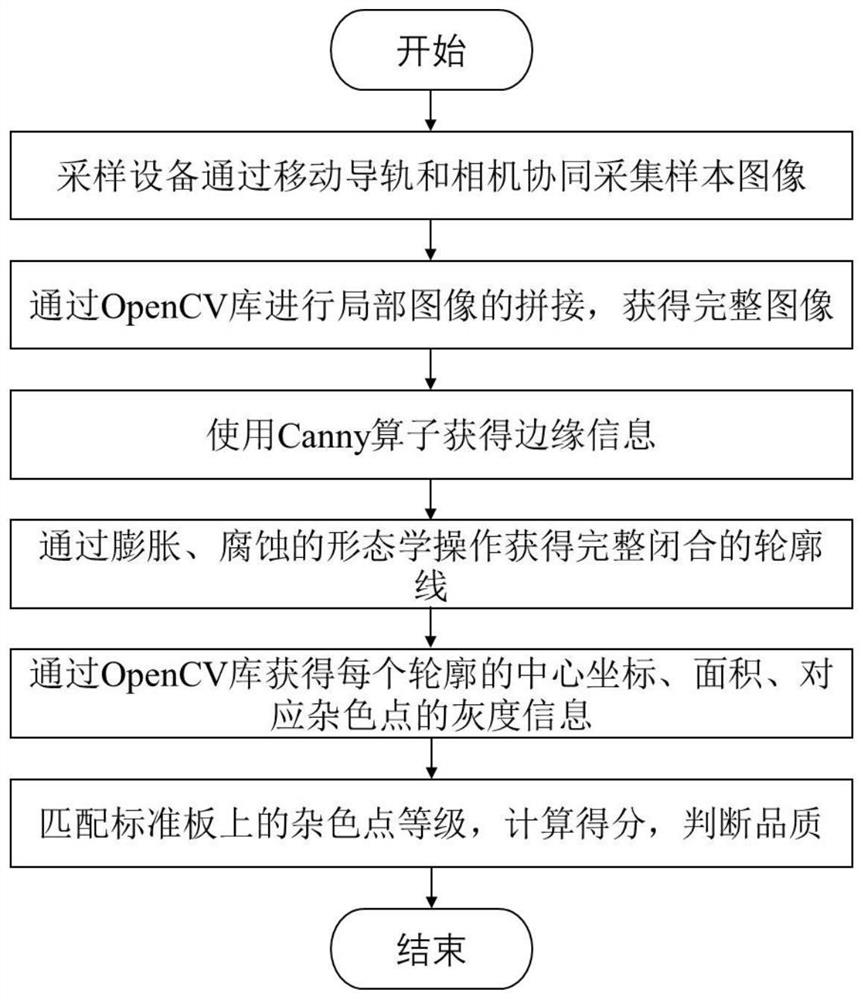

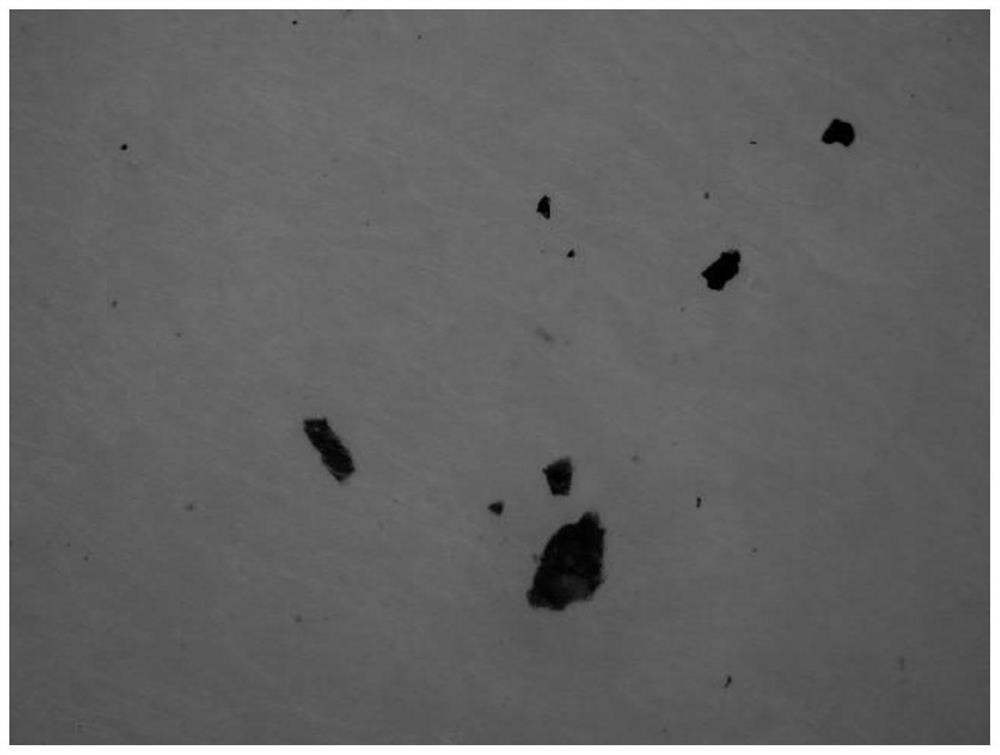

[0064] refer to Figure 1~6 As the first embodiment of the present invention, a method for judging the quality of variegated spots in recycled plastics is provided, which specifically includes:

[0065] S1: Obtain the image information of the target area and preprocess it. It should be noted that the preprocessing includes:

[0066] Use a CCD camera to obtain RGB images of recycled plastic samples;

[0067] If one image cannot cover all the sampling points, the CCD camera is used to obtain the block RGB image of the recycled plastic sample, and the image stitching is performed through the OpenCV library to obtain a complete sample image.

[0068] S2: Use the Canny operator to extract the edge of the preprocessed image information to obtain the contour of the noise point. What needs to be explained in this step is that obtaining the outline of noise points includes:

[0069] Convert the RGB three-channel image to a single-channel grayscale image;

[0070] Use the Canny ope...

Embodiment 2

[0129] refer to Figure 7 , is the second embodiment of the present invention, which is different from the first embodiment in that it provides a device for judging the quality of the variegated spots of recycled plastics, which specifically includes:

[0130] The material platform 100 is used to carry and fix the recycled plastic sample, on which a clamp 104 is arranged to fix the sample;

[0131] The camera 200 and the lens 203 are used to take images of plastic samples;

[0132] The focus knob 201 is used to focus the camera, and it needs to be adjusted to: the noise points that can be identified by the program meet the highest precision on the standard noise point comparison board;

[0133] The light source 202 is used to provide stable and fixed-brightness lighting, and the lighting brightness is uniform, which is beneficial to the stability of the edge extraction method;

[0134] The moving guide rail 101, on which the material platform is mounted, can move the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com