Waste building multi-layer plate thickness sorting machine

A multi-layer board and sorting machine technology, applied in sorting, computer control, mechanical measuring devices, etc., can solve the problems of waste of raw materials, labor and energy consumption, and achieve the effects of power reduction, saving raw materials and energy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

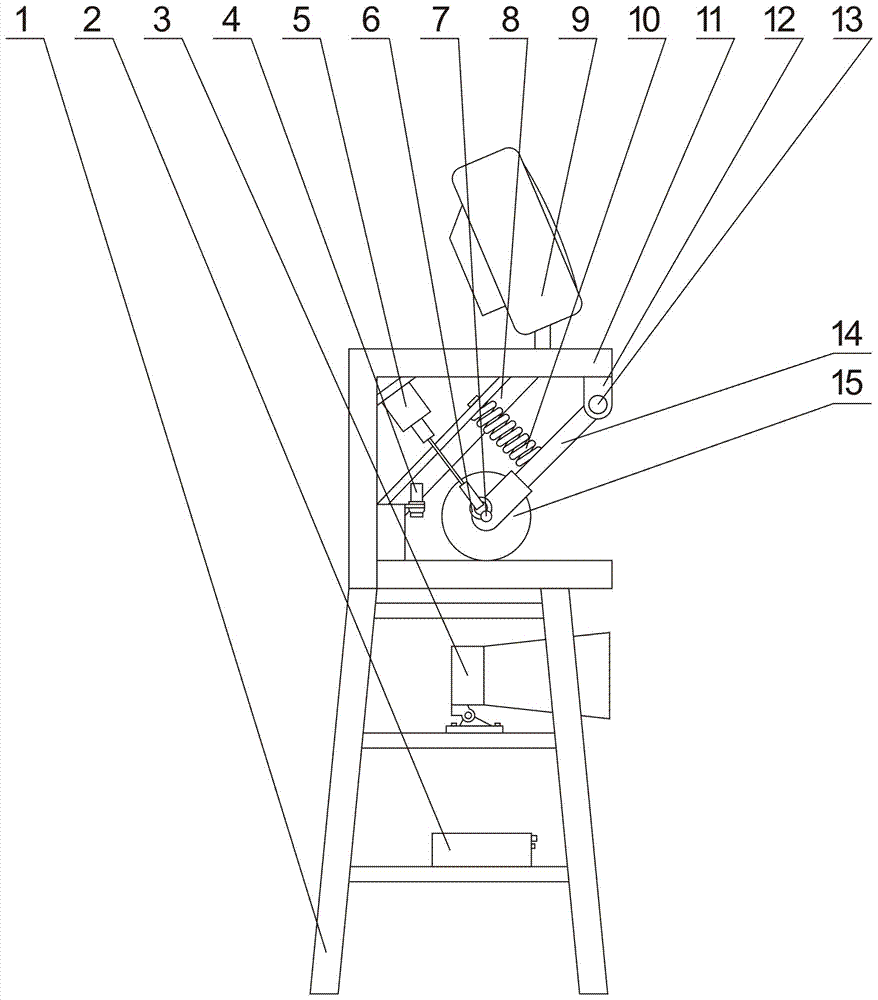

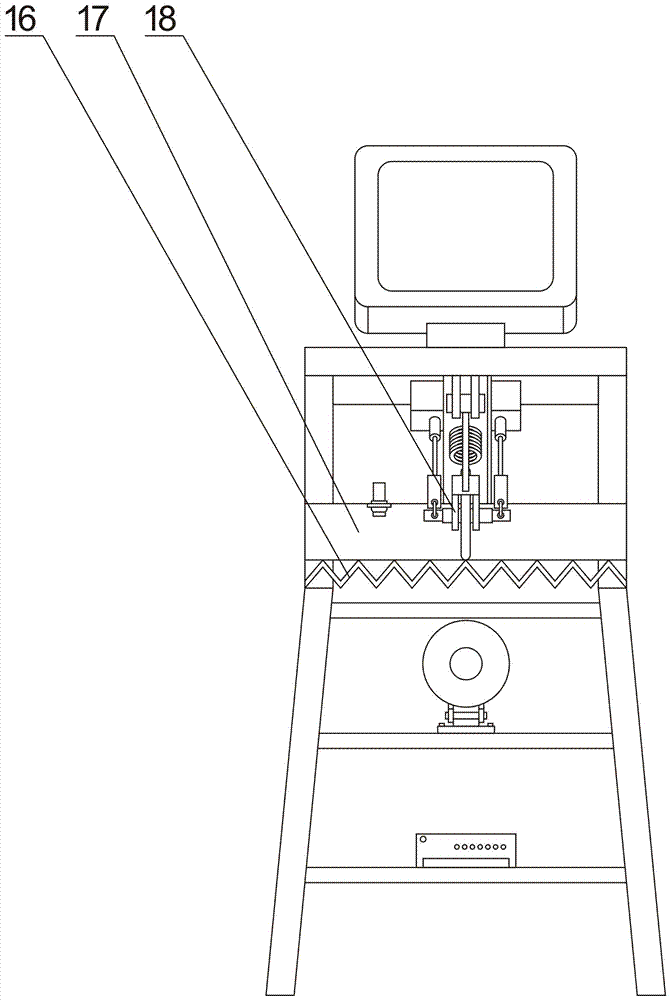

[0013] Embodiment 1, see attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , construction waste multi-layer board thickness sorting machine, comprises upper frame 11, lower frame 1, power amplifier 2, loudspeaker 3, display screen 9, is provided with a waveform console 16 on the plane that upper and lower frame connects, and waveform console A fixed plate 17 is fixedly connected to the rear end of the fixed plate, and a photoelectric switch 4 is installed on the upper edge of the fixed plate. Swing arm seat 12, one end of a swing arm is sleeved in the swing arm seat by bearing pin 13, a pressure spring 10 is fixedly connected to the middle part of the swing arm, the other end of the pressure spring is fixedly connected to the fixed frame, and the other end of the swing arm 14 is fixedly connected. Connect a roller frame 18, the roller 15 is sleeved in the roller frame by the roller shaft 7, the two ends of the roller shaft are all provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com