Heavy-load open-type gear lubricating grease and preparation method thereof

A gear grease, heavy-duty technology, applied in the field of grease, can solve the problems of reduced frictional resistance and high power energy consumption, and achieve the effects of reducing power consumption, reducing oil resistance loss and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

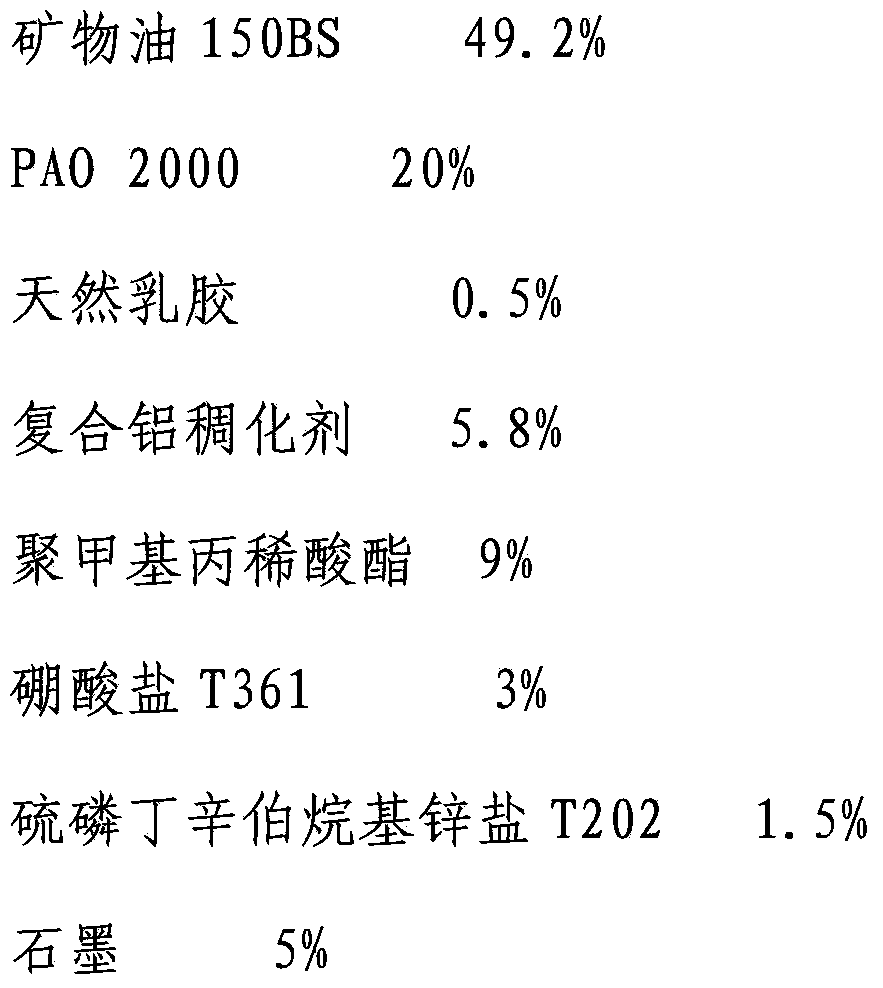

[0035] As a preferred embodiment, the composition of the heavy-duty open gear grease is as follows by weight percentage:

[0036]

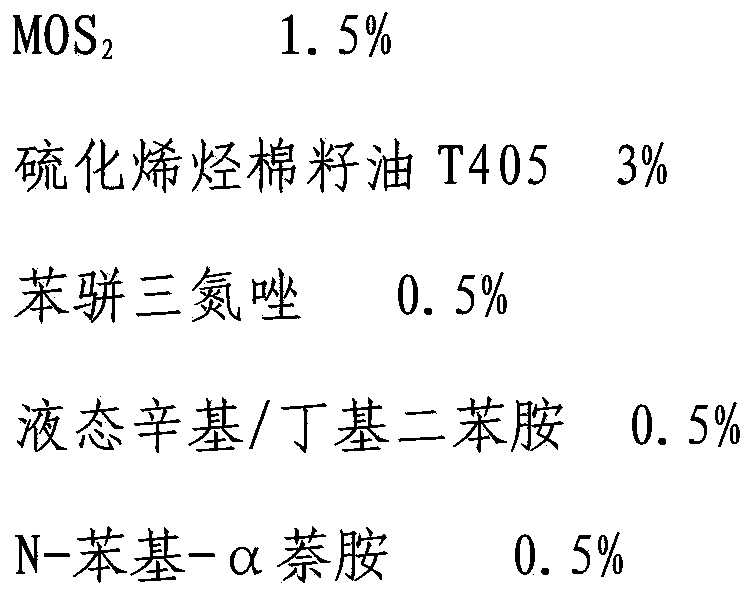

[0037]

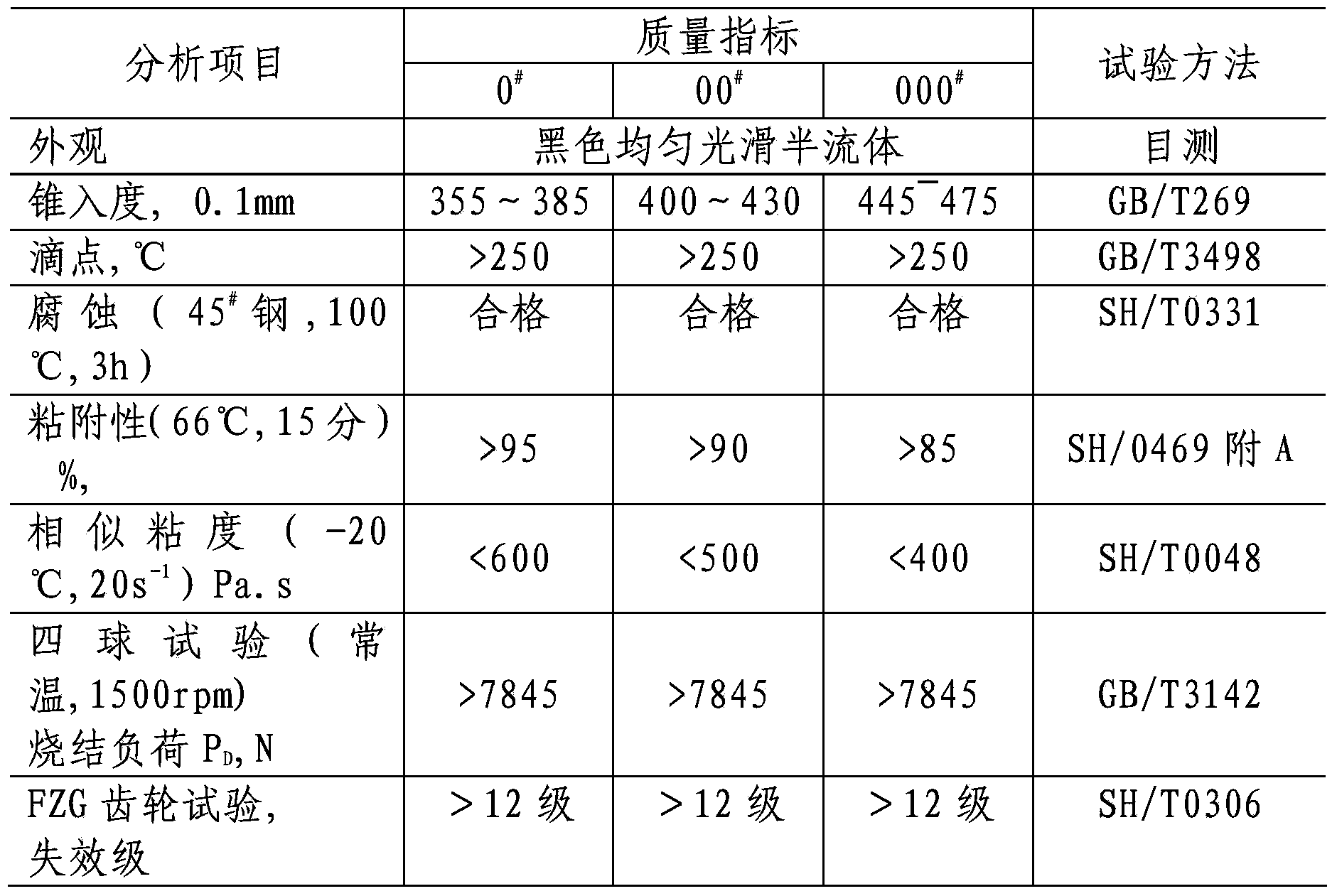

[0038] The invention is an energy-saving and environment-friendly heavy-duty open gear lubricating grease. The product is composed of high-viscosity refined mineral oil and high-viscosity synthetic oil thickened with a composite aluminum-based thickener, and multifunctional additives are added.

[0039] The base oil in the present invention is high-viscosity mineral oil and ultra-high-viscosity polyalphaolefin.

[0040] Thickening agent among the present invention is composite aluminum soap, is made by benzoic acid, fatty acid, aluminum isopropoxide trimer reaction, and benzoic acid is with C16 / C18 fatty acid together, with the aluminum in isopropoxide aluminum trimer The molar ratio is 1.9:1, and the molar ratio of benzoic acid to fatty acid is less than 1. .

[0041] The extreme pressure antiwear agent in the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com