Corrosion inhibitor for one-stage reverse osmosis water produced from sea water desalinization

A corrosion inhibitor and reverse osmosis technology, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of inhibiting pitting corrosion, alleviating corrosion effect, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

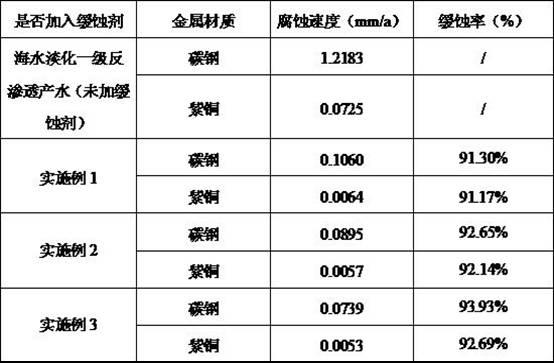

[0023] This example relates to a metal corrosion inhibitor in seawater desalination first-stage reverse osmosis product water. The compounded mass ratio of the corrosion inhibitor is 1:3, and the concentration of the compounded corrosion inhibitor is 20 mg / L, that is, sodium gluconate is 5 mg / L. L, sodium silicate is 15mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of the carbon steel and copper test pieces in the first-stage reverse osmosis product water of seawater desalination after 72 hours of couponing. The results are shown in Table 2.

Embodiment 2

[0025] This example relates to a carbon steel corrosion inhibitor in seawater desalination first-stage reverse osmosis product water. The mass compounding ratio of the corrosion inhibitor is 1:3, and the concentration of the compound corrosion inhibitor is 25mg / L, that is, sodium gluconate is 6.25 mg / L, sodium silicate is 18.75mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of the carbon steel and copper test pieces in the first-stage reverse osmosis product water of seawater desalination after 72 hours of couponing. The results are shown in Table 2.

Embodiment 3

[0027] This example relates to a carbon steel corrosion inhibitor in seawater desalination first-stage reverse osmosis product water. The compound mass ratio of the corrosion inhibitor is 1:2, and the concentration of the compound corrosion inhibitor is 30 mg / L, that is, sodium gluconate is 10 mg / L, sodium silicate is 20mg / L. Using the rotating coupon method, the corrosion rate and corrosion inhibition rate were calculated based on the weight loss of the carbon steel and copper test pieces in the first-stage reverse osmosis product water of seawater desalination after 72 hours of couponing. The results are shown in Table 2.

[0028] Table 2 Corrosion speed and corrosion inhibition rate of carbon steel in the above three examples

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com