Method for preparing electronic-grade nickel sulfate from nickel powder, crystallization device and control method of crystallization device

A crystallization device, technology of nickel sulfate, applied in the direction of crystallization adjustment/control, nickel sulfate, solution crystallization, etc., can solve the problems of increasing production cost and unable to meet the needs of nickel-cobalt-manganese ternary production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

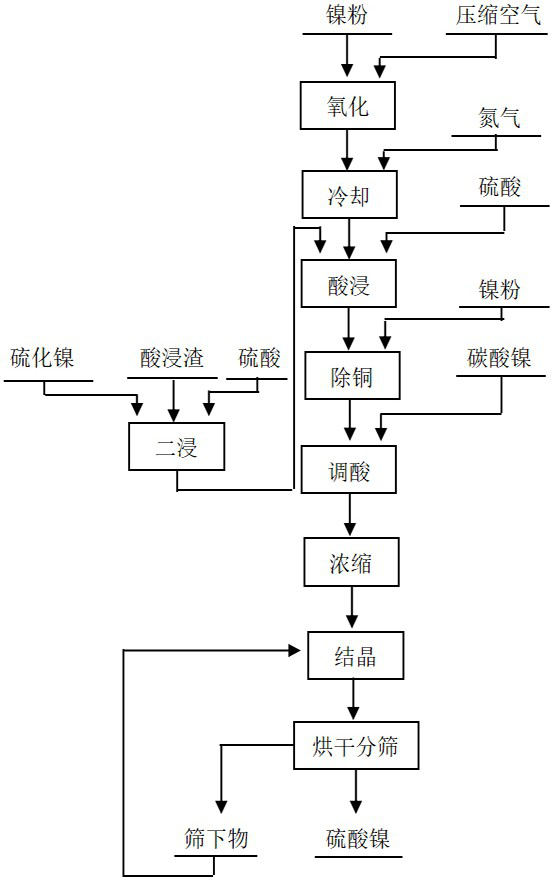

[0044] Implementation mode 1: if figure 1 A method for preparing electronic-grade nickel sulfate from nickel powder, comprising the following steps: oxidation, cooling, acid leaching, copper removal, acid adjustment, concentration, cooling crystallization, drying and sieving, and secondary immersion. The special features are:

[0045] Said oxidation: the temperature of nickel powder is controlled in the calcination furnace at 400-700°C, and 1-5m of compressed air is injected per kilogram of nickel powder 3 , react for 1.0-2.5 hours.

[0046]Further, the oxidation: the nickel powder is controlled in the calciner at a temperature of 450-600°C, preferably 500°C, and 3-4m of compressed air is injected per kilogram of nickel powder. 3 , react for 1.0-1.5 hours.

[0047] In some embodiments, the nickel powder is controlled at a temperature of 400°C, 450°C, 500°C, or 550°C in the calciner.

[0048] In some embodiments, the compressed air injected per kilogram of nickel powder is 1...

Embodiment approach 2

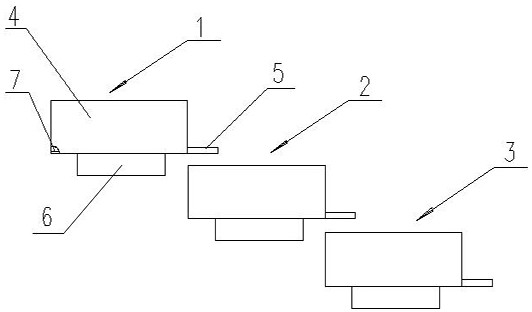

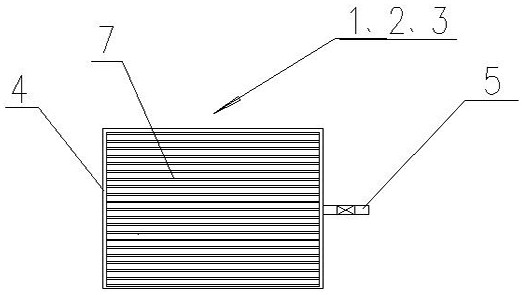

[0081] Implementation mode 2: if Figure 2-5 , a crystallization device for preparing electronic-grade nickel sulfate from nickel powder. The crystallization device is composed of three sets of crystallizers with the same structure connected in series, that is, the first-stage crystallizer 1, the second-stage crystallizer 2, and the third-stage crystallizer 3 are connected in series. The crystallizer is composed of a crystallization frame 4, an oscillator 6 arranged under the crystallization frame 4, and a liquid outlet 5 with a control valve at the liquid outlet of the crystallization frame 4. The crystallization frame 4 is made of a cuboid, and its special The advantage is that: the bottom of the crystallization frame 4 is evenly distributed with protruding strips 7 whose cross section is arc-shaped, and the distance S between two adjacent protruding strips 7 is 1 / 25-1 / 15 of the width of the crystallization frame 4 , the width b and height h of the raised strip 7 are both 1 / ...

Embodiment approach 3

[0090] Embodiment 3: the control method of the crystallization device of nickel powder preparation electronic grade nickel sulfate, take the following steps:

[0091] a. Start the first-stage crystallizer 1: the concentrated nickel sulfate solution flows into the first-stage crystallizer 1, open the oscillator 6, the frequency of the oscillator is based on the fact that the cobalt sulfate solution does not overflow the crystallization frame, and the temperature of the nickel sulfate solution After reaching 45°C, it flows into the second-stage crystallizer 2 from the liquid discharge port 5, and the crystallized matter in the crystallization frame 4 is collected and sieved to enter the next process.

[0092] b. Start the second-stage crystallizer 2: After the nickel sulfate liquid in the second-stage crystallizer 2 is put in, add the fine particle nickel sulfate crystallization of the sieved material of the screening process, and other operations are the same as the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com