Method for preparing high-toughness eutectic high-entropy alloy based on selective laser melting technology

A technology of laser selective melting and high-entropy alloys, which is applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve problems such as the inability to achieve high dimensional accuracy and geometric complexity of metal components, and limit engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

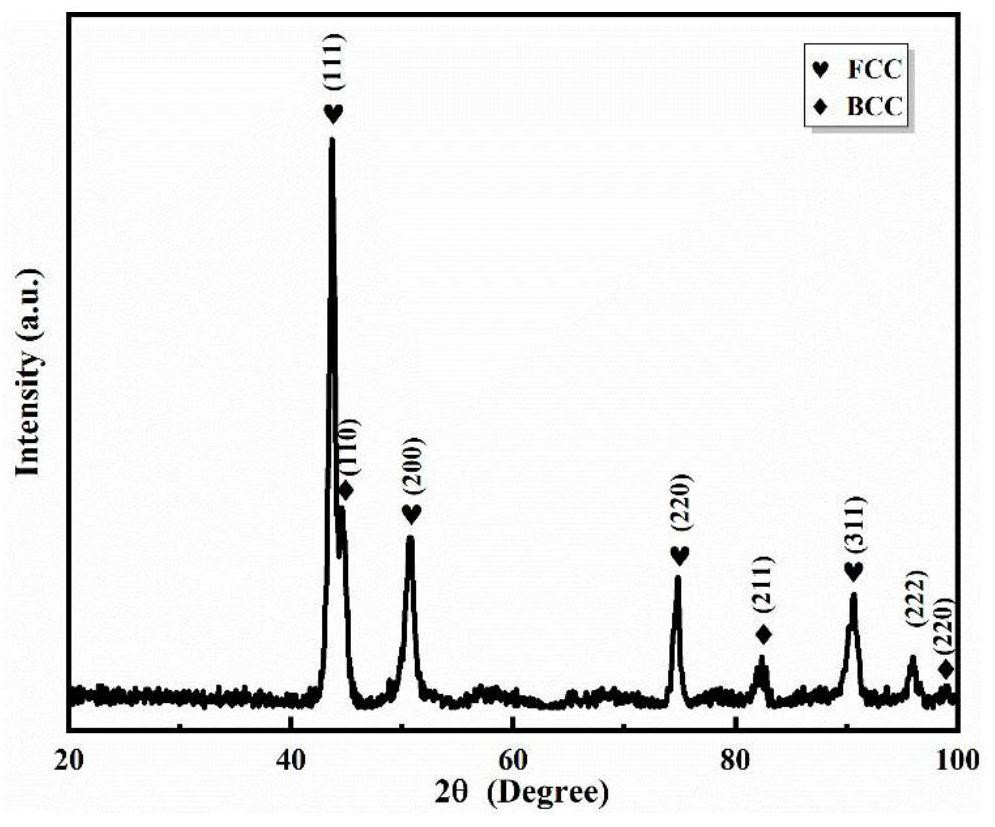

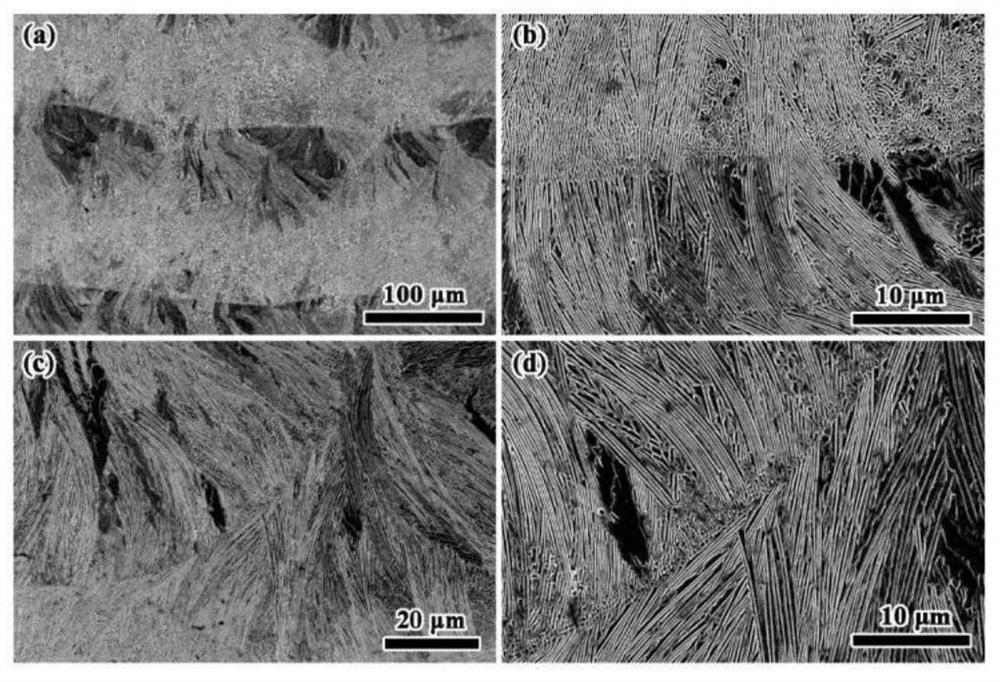

[0044] A method for preparing a high-strength and toughness eutectic high-entropy alloy based on laser selective melting technology, comprising the following steps:

[0045] (1) Put the gas-atomized AlCoCrFeNi pre-alloyed powder and Ni powder with a purity >99% into the ball mill tank of the planetary ball mill, then pour analytical pure alcohol to submerge the powder, control the ball-to-material ratio to 1:1, and use 200r / Min speed ball milling 4h, after ball milling, the product of ball milling is put into oven, is dried at 100 ℃ for 10h, obtains mixed powder; According to mole percentage, the content of AlCoCrFeNi pre-alloyed powder in described mixed powder is 48%, Ni The powder content is 52%; the particle size distribution of the gas-atomized AlCoCrFeNi pre-alloyed powder and the Ni powder with a purity >99% is independently 13-53 μm;

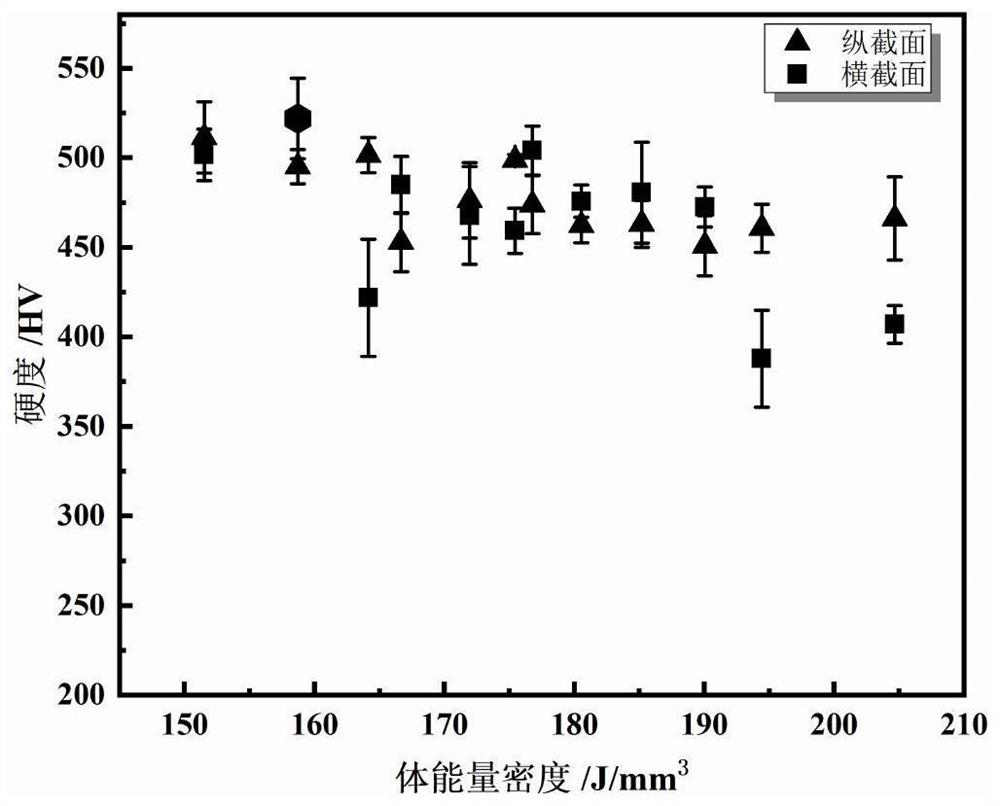

[0046] (2) Use Magics. software to establish a three-dimensional model of the formed part and set slices, and save it as a CLI. file; ...

Embodiment 2

[0048] The process parameters of laser selective melting and forming are set as follows: laser power is 350W, scanning speed is 660mm / s, powder layer thickness is 40μm, scanning distance is 75μm, and other conditions are the same as in Example 1.

Embodiment 3

[0050] The process parameters of selective laser fusion forming are set as follows: laser power 300W, scanning speed 630mm / s, powder layer thickness 50μm, scanning distance 75μm, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com