Pulverization matching-type multi-inlet medium ejector

An injector and multi-inlet technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of using passive, atomizing branch pipe flow can not be holed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

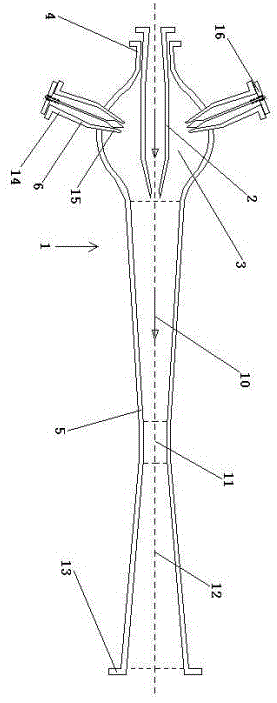

[0022] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

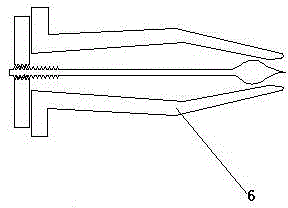

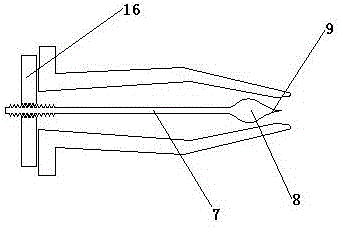

[0023] like Figure 1-6 As shown, the atomizing proportioning multi-entrance medium injector includes a pipe body 1 and a nozzle 2, and the pipe body 1 is provided with a vacuum chamber 3, a nozzle hole 4, a venturi tube 5 and an atomizing branch pipe 6, wherein the nozzle hole 4 and the Wen The pipe 5 is coaxially connected to both ends of the vacuum chamber, and two atomizing branch pipes 6 are connected to the side of the vacuum chamber 3 and obliquely to the axial side of the nozzle hole 4 . The angle between the axis of the atomizing branch pipe 6 and the axis of the venturi tube 5 is an obtuse angle, so that the steam flowing from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com