Hot rolling pickle sheet with high yield ratio

A technology of hot-rolled pickling and high yield ratio, applied in the field of hot-rolled pickled plates, to achieve the effects of eliminating yield platforms, reducing development costs, and shortening development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A variety of parts have been stamped and loaded into the vehicle, and the results show that GQRS can completely replace the ordinary cold plate, and it shows good mechanical properties and stamping performance. At present, the cabs of FAW J5 series trucks use ordinary cold plates St13 and St14. We applied the hot-rolled pickled plates with high yield ratio to this vehicle. Firstly, the chemical composition and mechanical properties of the materials were designed. The production process is under control. In addition, under a certain tensile strength, it is composed of the following chemical elements by weight ratio (Wt%): C 0.04, S 0.007, P0.015, Mn0.18, Si0.02, Als 0.040. In order to obtain a higher yield ratio, the rolling process strictly controls various conditions to obtain relatively fine grains, and the metallographic structure is ferrite plus a small amount of pearlite.

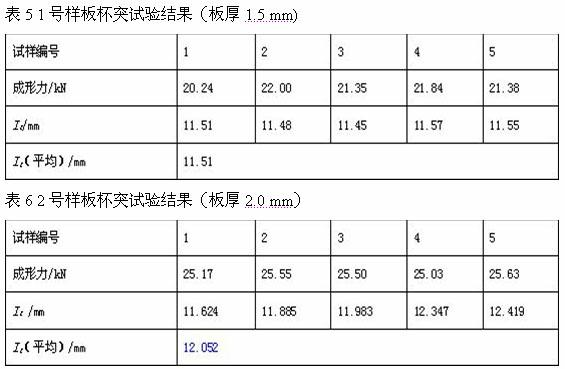

[0014] The hole expansion test and cupping test of simulated forming prove that GQRS materi...

Embodiment 2

[0022] With the help of CAE analysis means, the whole process of sheet metal stamping forming is simulated for the designed parts, so as to judge the rationality of product design and stamping process plan. The analysis of the formability and structural strength of the same parts under old and new materials shows that the developed GQRS can completely replace the traditional cold-rolled sheet, and shows good formability and mechanical properties, and can achieve the purpose of reducing weight to a certain extent .

[0023] Firstly, the CAE simulation analysis of the suspension reinforcement plate with relatively simple deformation and low formability requirements was carried out. The results show that both materials can meet the forming conditions mechanically, and can be completely replaced. After stamping with GQRS, they have been loaded and tested run.

[0024] Afterwards, CAE simulation analysis was carried out on beam parts with more complex deformation. Under the same b...

Embodiment 3

[0027] The hot-rolled pickled plate with high yield ratio is composed of the following chemical elements by weight ratio (Wt%): C 0.06, S 0.010, P 0.020, Mn 0.35, Si 0.03, Als 0.060.

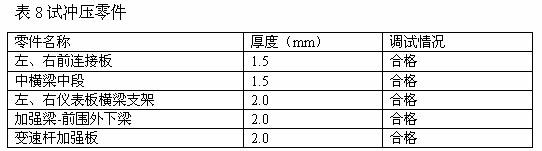

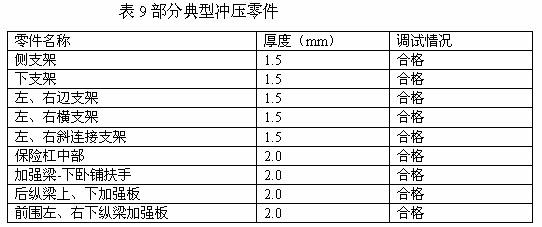

[0028] A variety of parts have been stamped and formed, and loaded and run. The results show that the performance is good. GQRS can completely replace the ordinary cold plate, and it shows good mechanical properties and stamping properties. Table 8 shows some complex and typical stamping parts processed by this kind of high yield ratio hot-rolled pickling plate.

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com