Glass anti-reflection coating liquid and application method of glass anti-reflection coating liquid in anti-reflection glass preparation

A technology of coating liquid and glass, applied in the direction of coating, etc., can solve the problem of reducing organic compounds and other problems, and achieve the effect of good adhesion performance of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Disperse 62.6 g of tetraethoxysilane in 90 g of ethanol, add 43.2 g of 0.5N nitric acid aqueous solution and stir at room temperature for 24 hours, and then concentrate the obtained silica sol by rotary evaporation to obtain 121 g of nano silica sol. 1.

[0021] Disperse 17.8 g of tetraethoxysilane in 108 g of ethanol, add 9.8 g of 0.16N ammonia water and stir for 24 hours at room temperature, and then concentrate the obtained silica sol by rotary evaporation to obtain 63 g of nano silica sol. 2.

[0022] The obtained nano-silica sol 2 is added to the nano-silica sol 1, and then 450 g of water is added, and the reaction is stirred at room temperature for 1 hour. Then, 0.2-1.2 g of oxalic acid is added, and the aqueous antireflection coating solution is obtained after uniform stirring.

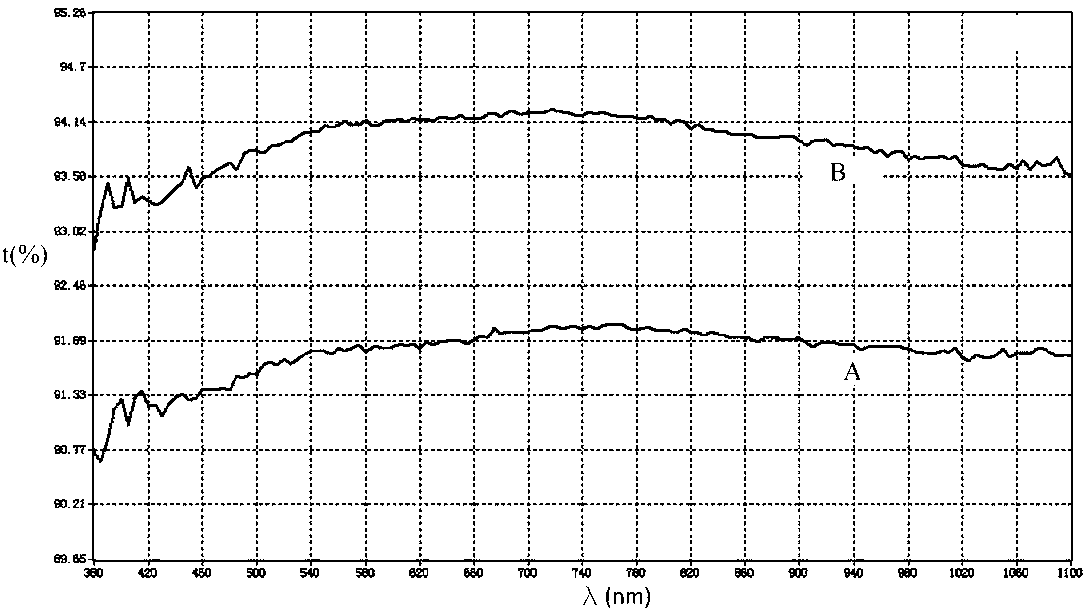

[0023] The glass substrate was washed with pure water and dried in an oven. After cooling, the colloidal solution was used to coat the glass substrate by roller coating, and then the film was ...

Embodiment 2

[0026] Disperse 62.1 g of triethoxymethylsilane in 80 g of isopropanol, add 37.8 g of 0.5N hydrochloric acid aqueous solution and stir at room temperature for 24 hours, and then concentrate the resulting silica sol by rotary evaporation to obtain 110 g Nano silica sol 3.

[0027] Disperse 17.8 grams of tetraethoxysilane in 108 grams of ethanol, add 9.8 grams of 0.1N ammonia water and stir at room temperature for 24 hours, and then concentrate the resulting silica sol by rotary evaporation to obtain 60 grams of nano silica sol 4 .

[0028] The obtained nano-silica sol 3 is added to the nano-silica sol 4, and 460 grams of water are added, and the reaction is stirred at room temperature for 1 hour, and then 0.2-1.2 terephthalic acid is added and stirred uniformly to obtain an aqueous antireflection coating solution.

[0029] The glass substrate is washed with pure water and dried in an oven. After cooling, the resulting colloidal solution is coated on the glass substrate by roll coatin...

Embodiment example 4

[0032] Disperse 62.1 grams of triethoxymethylsilane in 80 grams of isopropanol, add 37.8 grams of 0.5N hydrochloric acid aqueous solution, stir at room temperature for 24 hours, and concentrate the resulting silica sol by rotary evaporation to obtain 110 grams of nano silica sol 3.

[0033] Disperse 17.8 g of tetraethoxysilane in 108 g of ethanol, add 9.8 g of an aqueous solution containing 0.3 g of ethylamine to the above solution, heat the solution to 40°C, and stir the reaction for 24 hours. The resultant is obtained by rotary evaporation. The silica sol was concentrated to obtain 65 grams of nano silica sol 5.

[0034] Add the nano silica sol 3 to the nano silica sol 5, add 480 grams of water, stir at room temperature for 1 hour, add 0.2-1.2 m-tribenzoic acid, and stir evenly to obtain an aqueous antireflection coating solution.

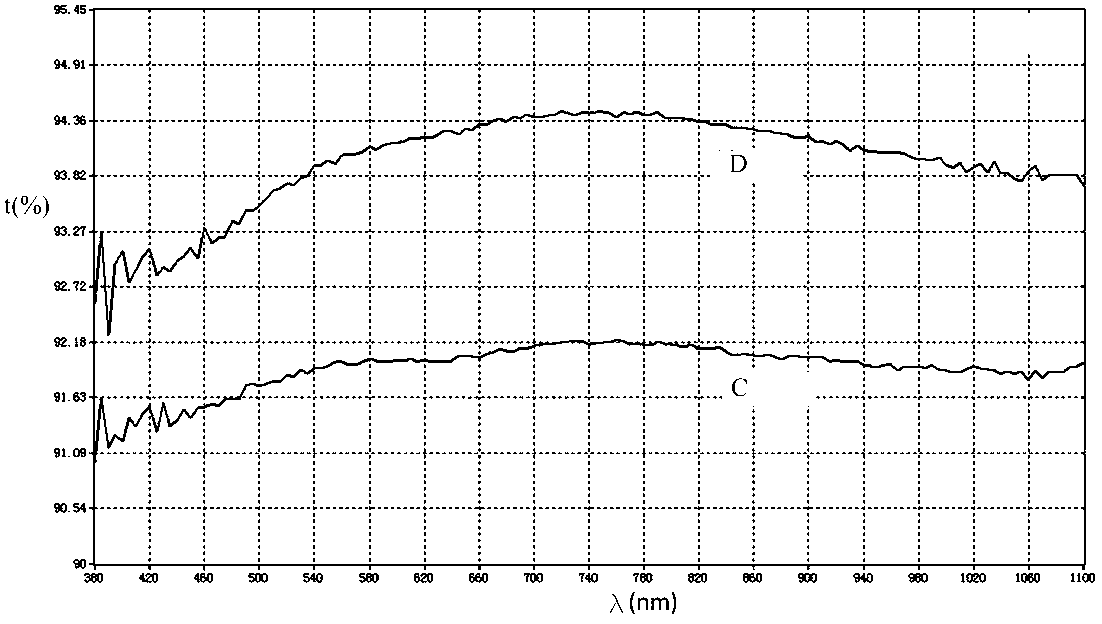

[0035] The glass substrate is washed with pure water, dried in an oven, and after cooling, the colloidal solution is applied to the glass substrate by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com