Micro concave roller and micro concave roller coating method

A technology of gravure roll and running direction, which is applied to the device for coating liquid on the surface, coating, textile and paper making, etc., and can solve the problems such as poor coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

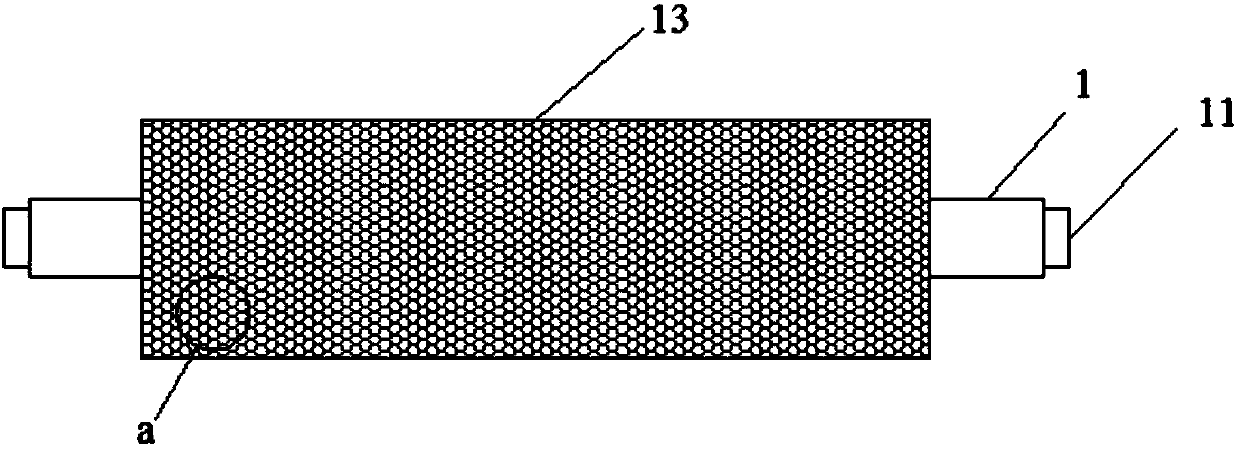

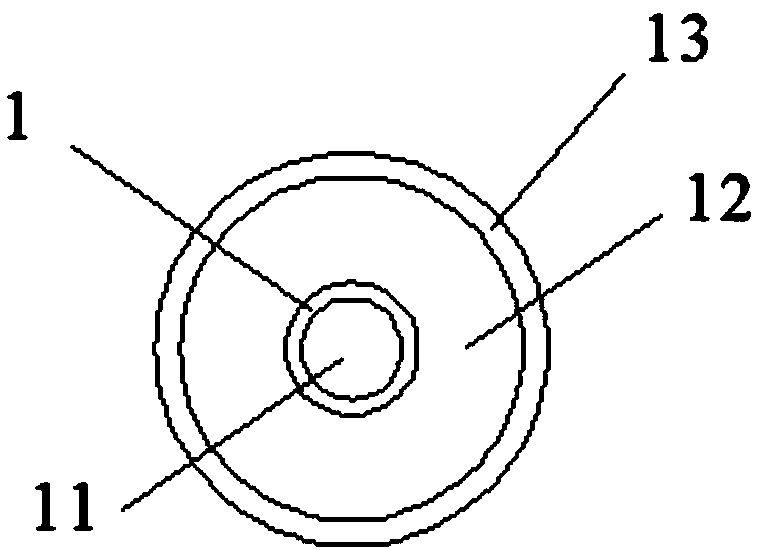

[0030] refer to Figure 1 to Figure 4 , a dimple roller according to the embodiment of the present application, including a main shaft 1;

[0031] Both ends of the main shaft 1 are fixed with bearing shafts 11;

[0032] A steel casing 12 is sheathed on the outside of the main shaft 1, and the length of the steel pipe casing 12 is shorter than the length of the main shaft 1;

[0033] The steel casing 12 is hard in texture, has a certain compressive capacity, and is not easy to be damaged during use or transportation.

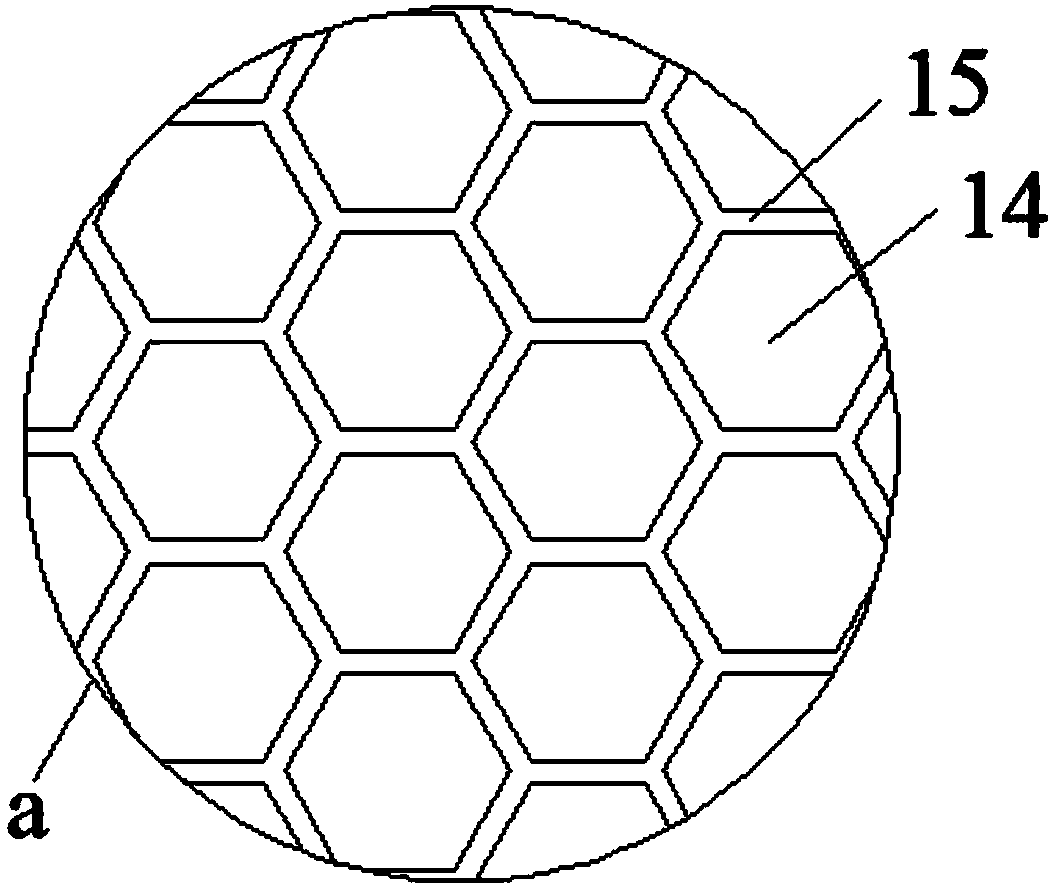

[0034] The axially outer surface of the steel casing 12 is covered with a hard ceramic tube 13;

[0035] The surface of the hard ceramic tube 13 is smooth and the friction force is small. When the paper is in contact with the hard ceramic tube 13, the damage to the paper can be reduced, thereby ensuring the quality of the product. In addition, ceramics have the advantages of almost no water absorption, high temperature resistance, corrosion resistance and wear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com