Water-based super-amphiphobic paint as well as preparation method and application thereof

A super-amphiphobic and coating technology, which is applied in coatings and other directions, can solve the problems of volatile organic solvents, rising coating costs, and unfavorable transportation, etc., and achieve the effects of reducing production costs, low VOC, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

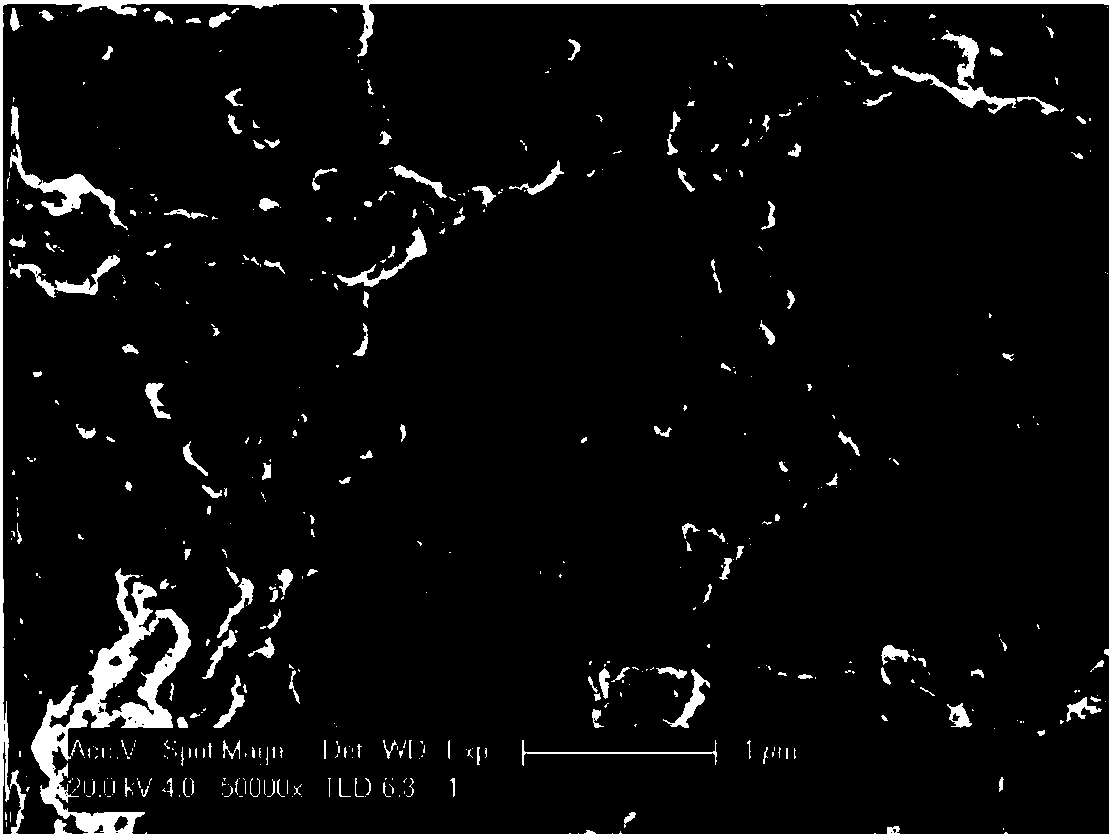

[0027] Mix 4mL ammonia water (mass fraction 28%, the same below) and 80mL deionized water, add 1.2g aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica mass concentration 10-20%) and 0.5g cationic fluorocarbon surfactant DuPont ForaperLe323, stir and disperse evenly. Afterwards, 0.6 mL of tetraethyl orthosilicate was added dropwise, and after stirring for 30 min, 0.6 mL of fluorosilane was added dropwise, and the aqueous superamphiphobic coating was obtained after magnetic stirring at 45° C. for 24 h. Then spray the coating on the glass slide at a high temperature of 160°C to obtain a water-based super-amphiphobic coating with a micro-nano composite structure. figure 1 A scanning electron microscope image of the coating.

Embodiment 2

[0029] The paint described in Example 1 was sprayed on the tinplate sheet and placed in a humid environment for 4 hours. Observe the formation of water droplets on the tinplate sheet every hour. The results show that part of the water vapor coated with the super-amphiphobic coating is difficult to grow on it, and there are only small water droplets on the surface after 4 hours. Whereas the water vapor nucleation speed was fast in the uncoated part, and the size of water droplets was large after 4 hours. This indicates that the superamphiphobic coating has excellent anti-condensation performance. figure 2 is an optical photograph of a partially coated tinplate sheet placed in a humid environment.

Embodiment 3

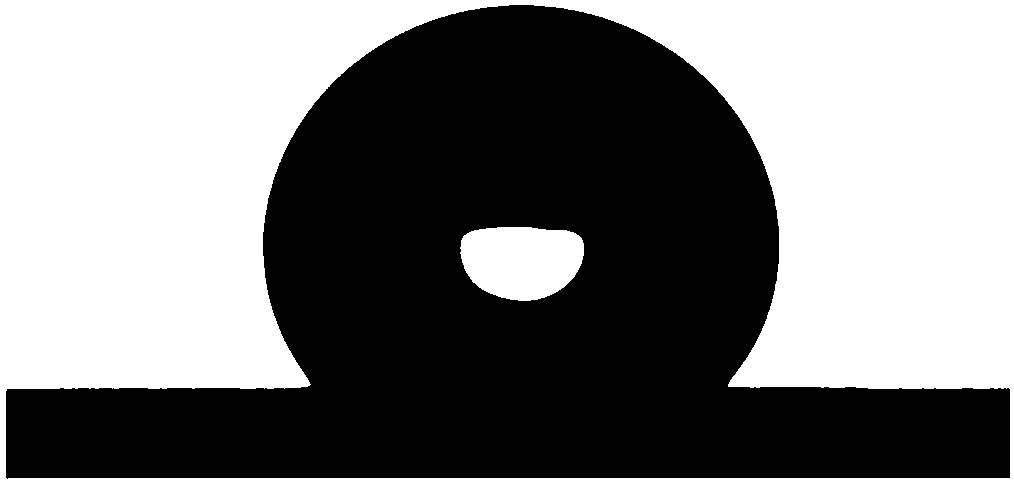

[0031] Mix 4mL ammonia water and 80mL deionized water evenly, add 1.2g aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica weight concentration 10-20%) and 0.5g anionic Fluorocarbon surfactant DuPontCapstoneFS-61, stir and disperse evenly. Afterwards, 0.6 mL of tetraethyl orthosilicate was added dropwise, and after stirring for 30 min, 0.6 mL of fluorosilane was added dropwise, and the aqueous superamphiphobic coating was obtained after magnetic stirring at 45° C. for 24 h. Then spray the coating on the glass slide at a high temperature of 300°C to obtain a water-based super-amphiphobic coating with a micro-nano composite structure. Its cetane contact angle is 160° and rolling angle is 3°. image 3 Optical picture of the contact angle of the coating (droplets are hexadecane).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com