Preparation method of glass fiber nonwoven fabric aramid coating diaphragm

A glass fiber and non-woven technology, which is applied to electrical components, circuits, battery pack components, etc., can solve the problems of excessive glass fiber non-woven pores, thermal shrinkage of diaphragms, and low mechanical strength of non-woven fabrics. The effect of improved thermal stability, good air permeability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

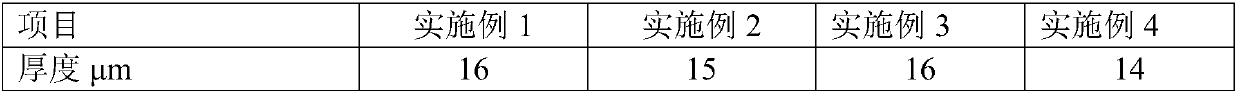

Embodiment 1

[0020] A kind of preparation method of glass fiber non-woven fabric aramid fiber coating diaphragm, comprises the following steps:

[0021] A. Preparation of aramid fiber slurry: by weight, take 6 parts of PMIA, 6 parts of alumina, 6 parts of methanol, and 6 parts of DMAC, heat and stir to dissolve, the dissolution temperature is 70 ° C, and mix evenly to obtain a mixture;

[0022] B. Preparation of the separator: the above mixture is coated on the glass fiber non-woven fabric by oil-based coating, and the aramid-coated separator is prepared through an extraction process.

[0023] Extraction process: 5 extraction tanks are set up, the extraction solvent is deionized water, and the extraction speed is 20m / min.

Embodiment 2

[0025] A kind of preparation method of glass fiber non-woven fabric aramid fiber coating diaphragm, comprises the following steps:

[0026] A. Preparation of aramid slurry: in parts by weight, take 10 parts of PMIA, 10 parts of alumina, 7 parts of propylene glycol, 8 parts of glycerin, and 15 parts of DMF, heat and stir to dissolve, and the dissolution temperature is 80 ° C. Mix Homogeneously, a mixture is obtained;

[0027] B. Preparation of the separator: the above mixture is coated on the glass fiber non-woven fabric by oil-based coating, and the aramid-coated separator is prepared through an extraction process.

[0028] Extraction process: set up 10 extraction tanks, the extraction solvent is ethanol, and the extraction speed is 60m / min.

Embodiment 3

[0030] A kind of preparation method of glass fiber non-woven fabric aramid fiber coating diaphragm, comprises the following steps:

[0031] A, the preparation of aramid fiber slurry: by weight, get 7 parts of PMIA, 8 parts of alumina, 3 parts of isoprene glycol, 4 parts of dipropylene glycol, 3 parts of tripropylene glycol, 4 parts of NMP, 4 parts of DMAC, 4 parts of DMF, heated and stirred to dissolve, the dissolution temperature is 90°C, mixed evenly to obtain a mixture;

[0032] B. Preparation of the separator: the above mixture is coated on the glass fiber non-woven fabric by oil-based coating, and the aramid-coated separator is prepared through an extraction process.

[0033] Extraction process: 7 extraction tanks are set up, the extraction solvent is acetone, and the extraction speed is 40m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com