Composite lithium ion battery ceramic diaphragm and preparation method thereof

A lithium-ion battery, ceramic diaphragm technology, applied in battery pack components, separators/films/diaphragms/spacers, circuits, etc. Powder drop and other problems, to achieve the effect of increasing rate discharge and cycle life, improving contact, and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Electrospinning solution preparation: PMMA is dissolved in NMP (N-methylpyrrolidone), the concentration of polyimide is 5wt%, and the viscosity of the polyimide solution is determined to be 100 mPa·S.

[0019] 2) Electrospinning: the prepared PMMA solution electrospinning solution is subjected to single-sided continuous electrospinning on a PET non-woven ceramic membrane through a nanofiber spinning machine, and the conditions for the electrospinning are: temperature 10°C , The voltage is 20kV, the spinning speed is 1g per minute per meter width, and the single-sided thickness of the nanofiber membrane is 1μm.

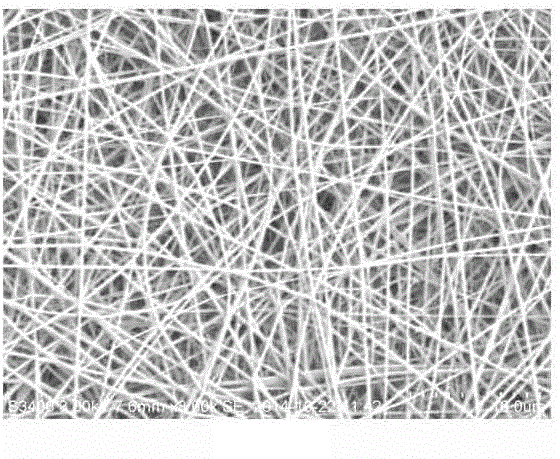

[0020] 3) Treat the composite membrane obtained after spinning: dry it in an oven at 120°C for 1 minute, to a composite lithium-ion battery ceramic separator, such as figure 1 Shown.

Embodiment 2

[0022] 1) Electrospinning solution preparation: PVA is dissolved in deionized water, the PVA mass volume ratio concentration is 5wt%, and the viscosity of the PVA solution is determined to be 1500 mPa.S.

[0023] 2) Electrospinning: The prepared PVA solution electrospinning solution is subjected to double-sided continuous electrospinning on a polyethylene ceramic diaphragm through a nanofiber spinning machine. The conditions for the electrospinning are: temperature 40°C, voltage 50kV, spinning speed is 10g per minute per meter width, and the single-sided thickness of nanofiber membrane is 10μm.

[0024] 3) The composite membrane obtained after spinning is processed: dried in an oven at 120°C for 5 minutes, to a composite lithium ion battery ceramic separator.

Embodiment 3

[0026] 1) Electrospinning solution preparation: Electrospinning solution preparation: Dissolve polyimide in DMAc (N,N-dimethylacetamide), the polyimide mass volume ratio concentration is 30wt%, measure the The viscosity of the polyimide solution was 3000 mPa.S.

[0027] 2) Electrospinning: The prepared polyimide solution electrospinning solution is subjected to double-sided continuous electrospinning on a PP / PE / PP ceramic coating diaphragm through a nanofiber spinning machine. The electrostatic spinning The conditions are: a temperature of 30°C, a voltage of 40kV, a spinning speed of 5g per minute per meter of width, and a single-sided thickness of the nanofiber membrane of 5μm.

[0028] 3) The composite membrane obtained after spinning is processed: dried in an oven at 120°C for 5 minutes to obtain a composite lithium ion battery ceramic separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com